What are river water level transmitters?

What are river water level transmitters?

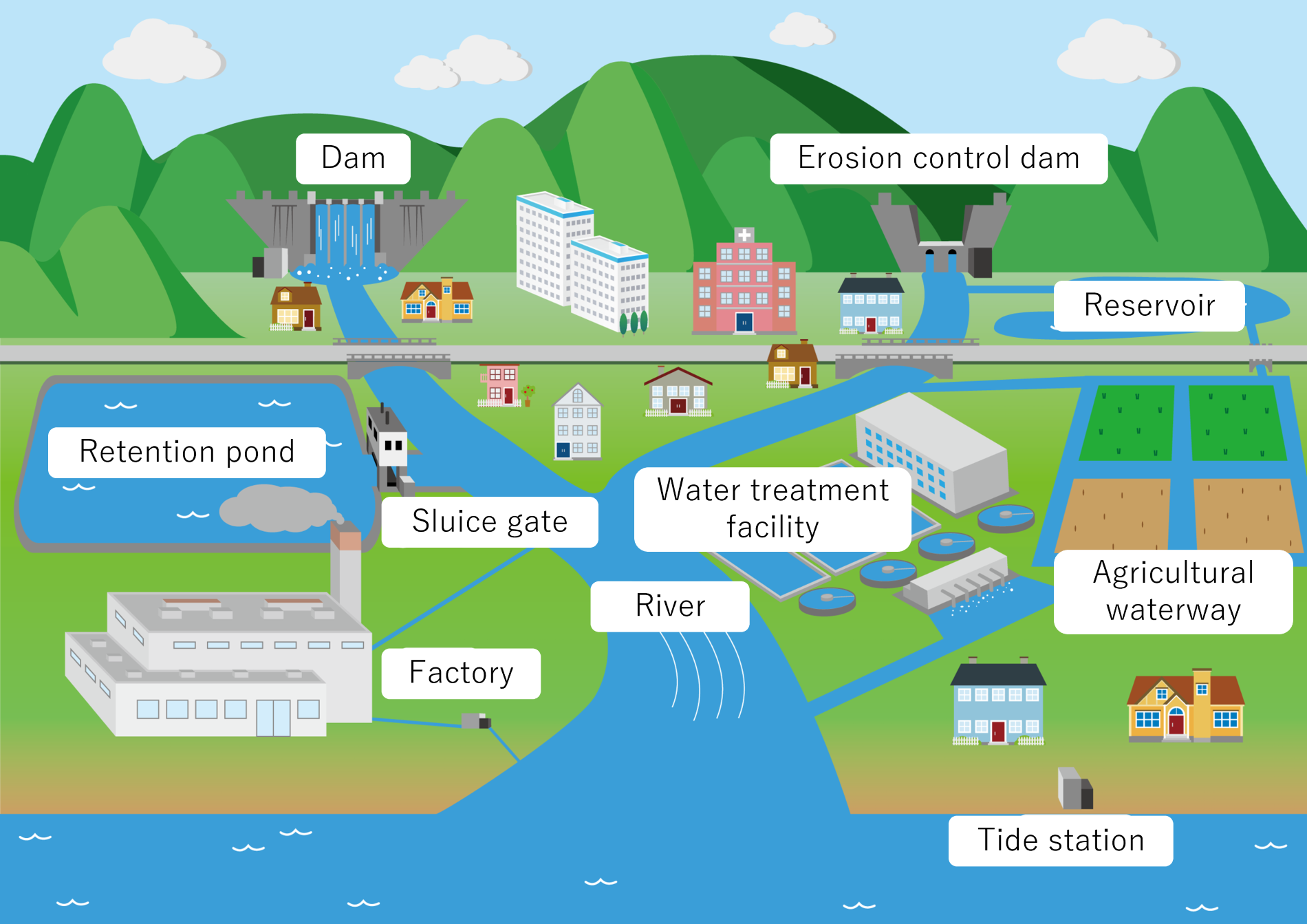

River water level transmitters are instruments used to measure and monitor water levels in rivers, dams, tidal areas and other bodies of water.

There are seven (7) popular types of transmitters such as radar type, ultrasonic type, float type, guide rope type, capacitance type, pressure type and differential pressure type.

Radar type river water level transmitter is the latest technology and known as the most reliable system.

There are seven (7) popular types of transmitters such as radar type, ultrasonic type, float type, guide rope type, capacitance type, pressure type and differential pressure type.

Radar type river water level transmitter is the latest technology and known as the most reliable system.

Type of River Water Level Transmitters

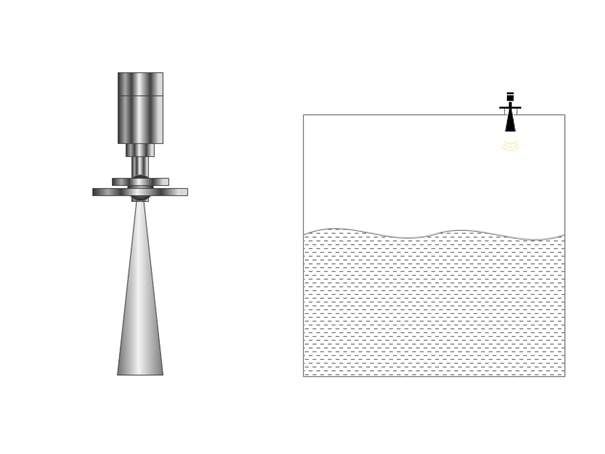

1. Radar Level Transmitter

■Principle

Radar Type River Water Level Transmitter is non-contact level meter. It is also called Microwave Level Transmitter.

It measures time it takes for microwave pulses emitted from sensor to be reflected from object to be measured and return to the sensor, and converts it to an empty scale distance.

■Features

- The sensor is not affected by temperature or gases.

- Radio waves are permeable, so they are not easily affected by dust or vapor.

- Radio waves are insensitive to small particles such as vapor.

- Since propagation principle is not based on air vibration, the measurement is not affected by wind.

■Disadvantages

- Reflected wave may penetrate weakly through measured object with low relative permittivity, making it impossible to measure.

- Vapor may be affected by condensation on tank ceiling. Especially when internal pressure is high, condensation is not water droplets but a water film.

Radio waves cannot penetrate the water film and cannot be measured. In such cases, air purging is effective.

Radar Type River Water Level Transmitter is non-contact level meter. It is also called Microwave Level Transmitter.

It measures time it takes for microwave pulses emitted from sensor to be reflected from object to be measured and return to the sensor, and converts it to an empty scale distance.

■Features

- The sensor is not affected by temperature or gases.

- Radio waves are permeable, so they are not easily affected by dust or vapor.

- Radio waves are insensitive to small particles such as vapor.

- Since propagation principle is not based on air vibration, the measurement is not affected by wind.

■Disadvantages

- Reflected wave may penetrate weakly through measured object with low relative permittivity, making it impossible to measure.

- Vapor may be affected by condensation on tank ceiling. Especially when internal pressure is high, condensation is not water droplets but a water film.

Radio waves cannot penetrate the water film and cannot be measured. In such cases, air purging is effective.

Matsushima Measure Tech Radar Type River Water Level Transmitter is a registered product of NETIS (New Technology Information System) authorized by the government (MLIT), and also the disaster prevention system at STePP (Sustainable Technology Promotion Platform) of UNIDO (United Nations Industrial Organization).

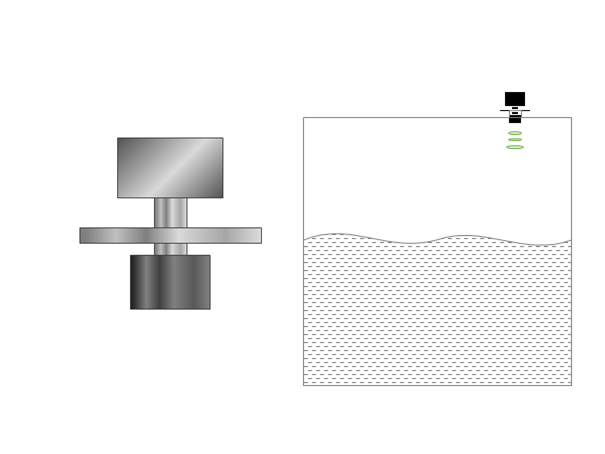

2. Ultrasonic Level Transmitter

■Principle

This is non-contact level meter that uses ultrasonic waves. Ultrasonic level meter measures time it takes for ultrasonic pulse to be emitted from sensor, reflected from object to be measured, and returned to sensor, and converts it into an empty distance.

■Features

Level measurement can be done relatively inexpensively and without contact.

■Disadvantages

- If dust, steam, or gas is generated, it will interfere with air vibrations and attenuate ultrasonic waves, leading to phenomena such as skipped instructions and erratic instructions.

We do not recommend using ultrasonic waves in environments where visibility is poor due to dust or steam and the liquid level cannot be seen.

- Steam also causes condensation on transmitting surface, leading to unnecessary reflections and attenuation of reflected waves, which can cause skipped indications or erratic indications.

- If there is temperature gap or generation of gas within measurement area, speed of sound will change and an error will occur.

This is non-contact level meter that uses ultrasonic waves. Ultrasonic level meter measures time it takes for ultrasonic pulse to be emitted from sensor, reflected from object to be measured, and returned to sensor, and converts it into an empty distance.

■Features

Level measurement can be done relatively inexpensively and without contact.

■Disadvantages

- If dust, steam, or gas is generated, it will interfere with air vibrations and attenuate ultrasonic waves, leading to phenomena such as skipped instructions and erratic instructions.

We do not recommend using ultrasonic waves in environments where visibility is poor due to dust or steam and the liquid level cannot be seen.

- Steam also causes condensation on transmitting surface, leading to unnecessary reflections and attenuation of reflected waves, which can cause skipped indications or erratic indications.

- If there is temperature gap or generation of gas within measurement area, speed of sound will change and an error will occur.

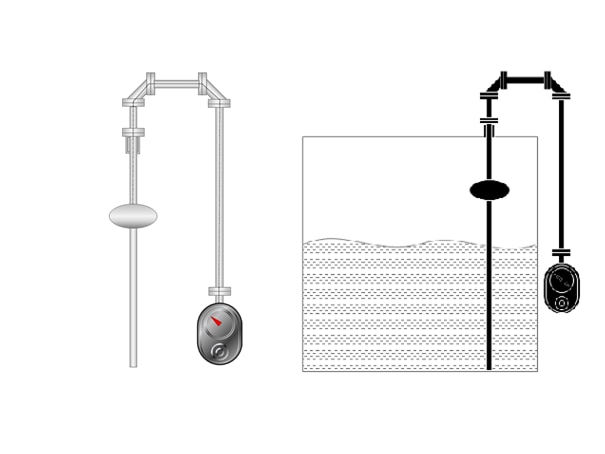

3. Float Level Transmitter

■Principle

Float type level meter uses float suspended from stainless steel tape to float on liquid surface and follow fluctuations in liquid level. Empty distance is measured by constantly measuring length of tape. There are float spring balance type, sealed pipe type, and counterweight type.

■Features

It has a simple structure and is widely used for liquid level detection in large and small tanks due to its accuracy and durability.

■Disadvantages

- Affected by adhesion.

If there is dirt or floating matter in liquid, it will gradually adhere to or stick to moving parts, obstructing movement of the float, and leading to false detection or failure to detect.

For example, when used for dosing control, the float does not move, so the liquid level cannot be recognized and there is a risk of overflow.

In the case of chemical liquid tanks, crystallization occurs in areas exposed to air, and a similar phenomenon may occur.

- Lack of maintainability due to many consumables.

- There is an error due to the accumulation of solids on the float.

- When used inside a breakwater pipe, float may not move properly due to adhesion and may malfunction.

Float type level meter uses float suspended from stainless steel tape to float on liquid surface and follow fluctuations in liquid level. Empty distance is measured by constantly measuring length of tape. There are float spring balance type, sealed pipe type, and counterweight type.

■Features

It has a simple structure and is widely used for liquid level detection in large and small tanks due to its accuracy and durability.

■Disadvantages

- Affected by adhesion.

If there is dirt or floating matter in liquid, it will gradually adhere to or stick to moving parts, obstructing movement of the float, and leading to false detection or failure to detect.

For example, when used for dosing control, the float does not move, so the liquid level cannot be recognized and there is a risk of overflow.

In the case of chemical liquid tanks, crystallization occurs in areas exposed to air, and a similar phenomenon may occur.

- Lack of maintainability due to many consumables.

- There is an error due to the accumulation of solids on the float.

- When used inside a breakwater pipe, float may not move properly due to adhesion and may malfunction.

4. Guided Wave Level Transmitter

■Principle

Guided Wave Level Transmitter emits microwave pulses along a lobe hanging from tank ceiling into tank, measures time it takes for microwaves reflected from object to return to sensor, and converts it into an empty distance. doing.

■Features

Like non-contact ultrasonic or microwave Level Transmitters, there is no radiation angle, making it suitable for installation in narrow spaces.

■Disadvantages

- Severe adhesion to probe may result in erroneous measurements.

- If wire kinks, wire breaks, or adhesion occur, noise will be reflected, making it easier to make incorrect measurements.

- If there is dirt, floating matter, or crystallized components in liquid, they will gradually grow to adhere to the probe, leading to generation of incorrect reflected waves.

As a result, there is a risk that correct reflected waves may not be detected and measurements may be made incorrectly, leading to events such as emptying tank without realizing it.

Guided Wave Level Transmitter emits microwave pulses along a lobe hanging from tank ceiling into tank, measures time it takes for microwaves reflected from object to return to sensor, and converts it into an empty distance. doing.

■Features

Like non-contact ultrasonic or microwave Level Transmitters, there is no radiation angle, making it suitable for installation in narrow spaces.

■Disadvantages

- Severe adhesion to probe may result in erroneous measurements.

- If wire kinks, wire breaks, or adhesion occur, noise will be reflected, making it easier to make incorrect measurements.

- If there is dirt, floating matter, or crystallized components in liquid, they will gradually grow to adhere to the probe, leading to generation of incorrect reflected waves.

As a result, there is a risk that correct reflected waves may not be detected and measurements may be made incorrectly, leading to events such as emptying tank without realizing it.

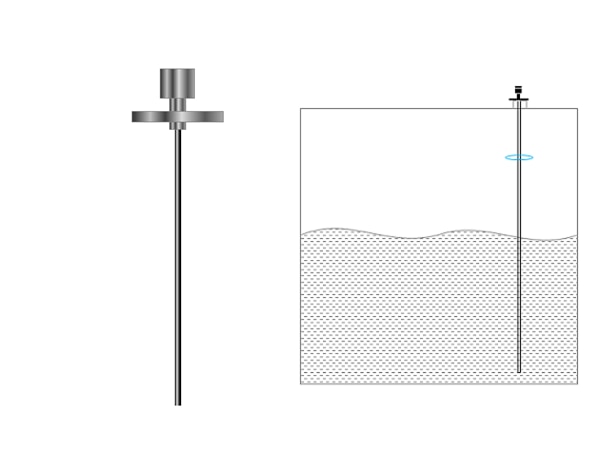

5. Capacitance Level Transmitter

■Principle

A capacitance level meter is also called a capacitance level meter. A capacitor is formed by the probe electrode hanging from the tank ceiling into the tank and the tank wall. When an object to be measured enters between the electrodes, the capacitance changes in proportion to the amount. This is measured and converted into storage level.

■Features

Suitable for measurements in narrow spaces.

■Disadvantages

- Since it is a contact type, there is a possibility of contamination by foreign matter.

- It is necessary to empty the tank and perform zero adjustment.

- Errors occur when measuring objects whose relative permittivity changes.

A capacitance level meter is also called a capacitance level meter. A capacitor is formed by the probe electrode hanging from the tank ceiling into the tank and the tank wall. When an object to be measured enters between the electrodes, the capacitance changes in proportion to the amount. This is measured and converted into storage level.

■Features

Suitable for measurements in narrow spaces.

■Disadvantages

- Since it is a contact type, there is a possibility of contamination by foreign matter.

- It is necessary to empty the tank and perform zero adjustment.

- Errors occur when measuring objects whose relative permittivity changes.

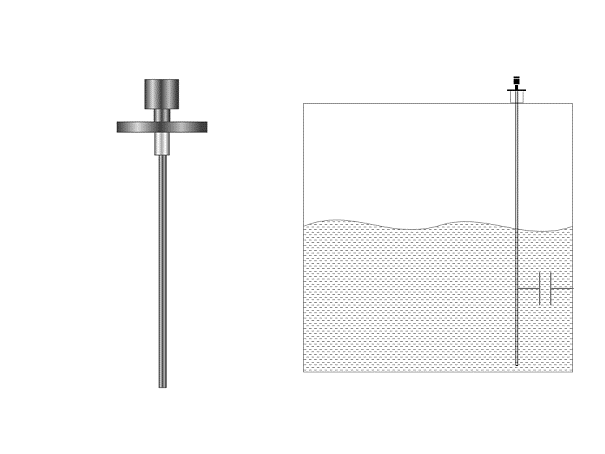

6. Pressure Level Transmitter

■Principle

A pressure type Level Transmitter (Throwing type Radar Type River Water Level Transmitter) uses a diaphragm to capture changes in liquid pressure due to liquid level and converts it into a storage level.

However, it must be used under condition that pressure inside tank is atmospheric pressure.

■Features

Easy to install even in places with limited installation space.

■Disadvantages

- If there are many foams in liquid, pressure will be uneven and accuracy will deteriorate.

- Accuracy will deteriorate if there is a lot of adhesion or solid matter settling. - If liquid pressure changes depending on specific gravity of the liquid, adjustment is required.

- When performing maintenance, tank must be emptied.

- When used to measure water levels in rivers, etc., there is a risk that debris or driftwood washed away by muddy currents caused by heavy rain may collide with the sensor and cause it to malfunction.

A pressure type Level Transmitter (Throwing type Radar Type River Water Level Transmitter) uses a diaphragm to capture changes in liquid pressure due to liquid level and converts it into a storage level.

However, it must be used under condition that pressure inside tank is atmospheric pressure.

■Features

Easy to install even in places with limited installation space.

■Disadvantages

- If there are many foams in liquid, pressure will be uneven and accuracy will deteriorate.

- Accuracy will deteriorate if there is a lot of adhesion or solid matter settling. - If liquid pressure changes depending on specific gravity of the liquid, adjustment is required.

- When performing maintenance, tank must be emptied.

- When used to measure water levels in rivers, etc., there is a risk that debris or driftwood washed away by muddy currents caused by heavy rain may collide with the sensor and cause it to malfunction.

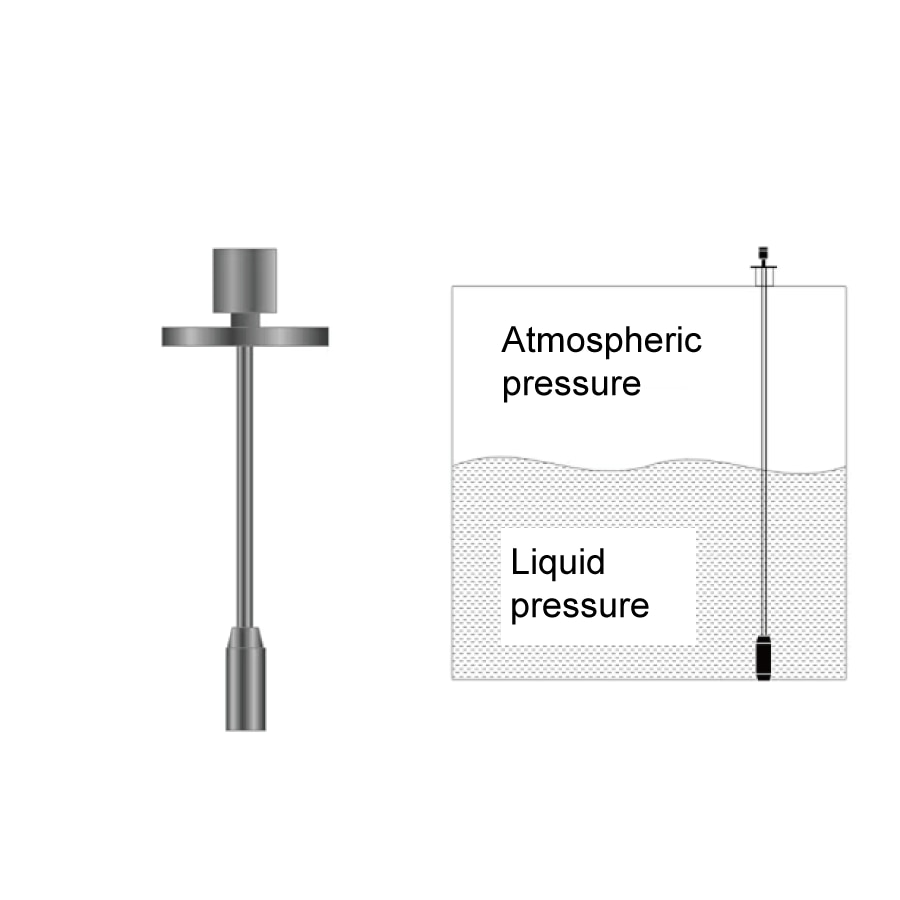

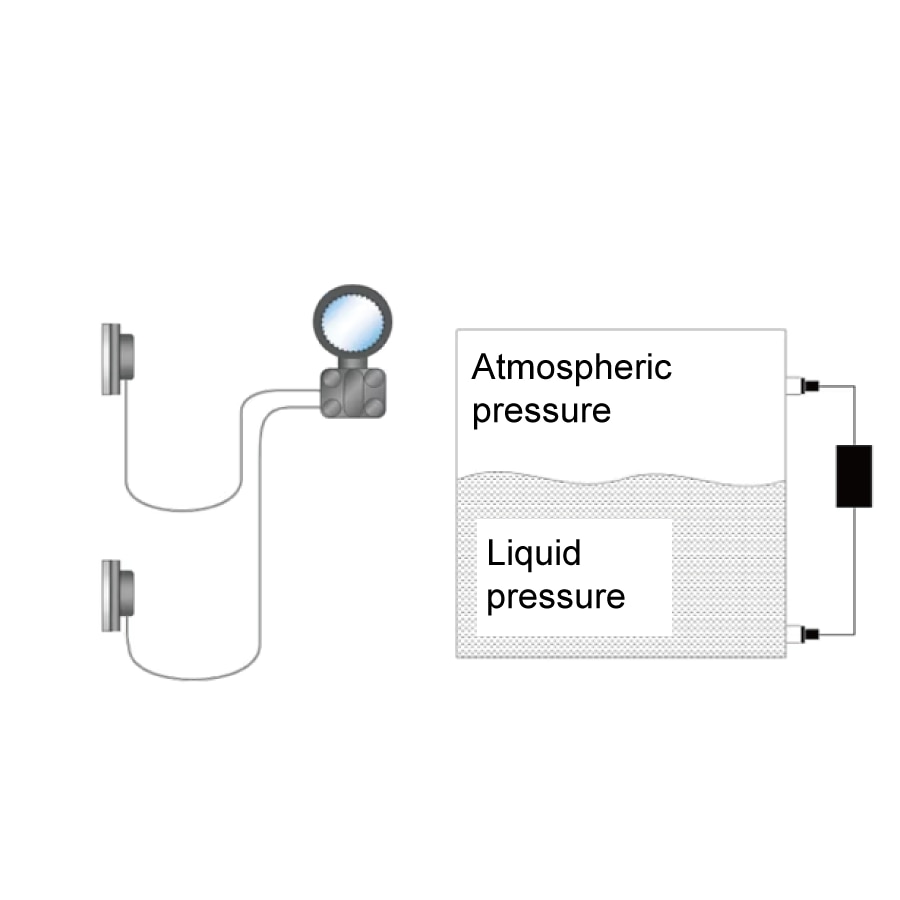

7. Differential Pressure Level Transmitter

■Principle

A differential pressure gauge consists of two parts: a diaphragm that measures liquid pressure and a diaphragm that measures tank internal pressure. Calculate storage level by subtracting tank internal pressure from liquid pressure.

■Features

Measurements can be made without being affected by pressure changes inside tank.

■Disadvantages

- If there are many air foams inside, pressure will be uneven and accuracy will deteriorate.

- Accuracy will deteriorate if there is a lot of adhesion or sedimentation of solid matter.

- If liquid pressure changes depending on specific gravity of liquid, adjustment is required.

- When performing maintenance, tank must be emptied.

A differential pressure gauge consists of two parts: a diaphragm that measures liquid pressure and a diaphragm that measures tank internal pressure. Calculate storage level by subtracting tank internal pressure from liquid pressure.

■Features

Measurements can be made without being affected by pressure changes inside tank.

■Disadvantages

- If there are many air foams inside, pressure will be uneven and accuracy will deteriorate.

- Accuracy will deteriorate if there is a lot of adhesion or sedimentation of solid matter.

- If liquid pressure changes depending on specific gravity of liquid, adjustment is required.

- When performing maintenance, tank must be emptied.

Related products

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

Please feel free to contact us if you have any inquiries.

Click here to download documents.

© Matsushima Measure Tech Co., Ltd.