What are dust monitors?

What are dust monitors?

Dust monitors are measuring instruments that measure dust concentration (mg/m3) in the air and there are 3 types which are triboelectric, light scattering and light transmission principles.

A Particle counter is one of the kind but it measures number of physical microparticles (pcs/m3) instead of concentration (mg/m3).

A Particle counter is one of the kind but it measures number of physical microparticles (pcs/m3) instead of concentration (mg/m3).

1. Working principle of dust monitors

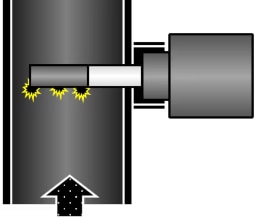

Triboelectric Dust Monitor

Triboelectric charging occurs when two materials are brought into contact then separated or slide against each other. Triboelectric dust monitor receives the electrostatic movement at the probe and converts them into analog signal in proportion to the dust concentration.

Triboelectric charging occurs when two materials are brought into contact then separated or slide against each other. Triboelectric dust monitor receives the electrostatic movement at the probe and converts them into analog signal in proportion to the dust concentration.

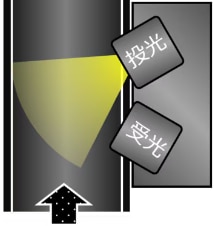

Light Scattering Dust Monitor

Light scattering dust monitor emits light into the process, receives light scattered from particles and count them as dust concentration signal. Basic principle is same as the particle counter. Refer to the below "2. Working principle of particle counter".

Light scattering dust monitor emits light into the process, receives light scattered from particles and count them as dust concentration signal. Basic principle is same as the particle counter. Refer to the below "2. Working principle of particle counter".

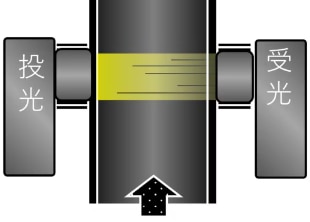

Light Transmission Dust Monitor

Light transmission dust monitor emits light from emitter and the receiver receives the light attenuated by flying dust in between. This attenuation is in proportion to the dust concentration.

Light transmission dust monitor emits light from emitter and the receiver receives the light attenuated by flying dust in between. This attenuation is in proportion to the dust concentration.

2. Working principle of particle counter

Particle counters use the light scattering method.

It sucks ambient air from the inlet nozzle and emits laser light to the area.

Then, emitted light scatters when it interacts with particles.

A photodiode in the particle counter detects the scattered light and converts into an electrical signal.

Particle size is determined based on the strength of the voltage signal and number of particles is calculated by number of waveforms.

It sucks ambient air from the inlet nozzle and emits laser light to the area.

Then, emitted light scatters when it interacts with particles.

A photodiode in the particle counter detects the scattered light and converts into an electrical signal.

Particle size is determined based on the strength of the voltage signal and number of particles is calculated by number of waveforms.

3. Difference between particle counters and dust monitors

Main difference between particle counters and dust monitors is the unit of measurement.

Particle counters measure "number of particles in the air (pcs/m3)" and dust monitors measure "particle concentration in the air (mg/m3)".

In case of low dust concentration situation, it is better to use particle counters (pcs/m3) because it's resolution is high and dust concentration value (mg/m3) is too low to use dust monitors.

But on the other hand, particle counter value (pcs/m3) becomes too high and difficult to make judgement in case of high dust concentration.

In this case, it is better convenient to use dust monitors (mg/m3).

Easier way to make judgement whether particle counters or dust monitors should be used is whether the dust concentration to be measured is higher or lower than the concentration level of general office or suburban outdoor.

Dust monitors are better in case it's higher than it.

Particle counters are better if it's lower than it.

In addition, particle counters are single measurement method.

Dust monitors are continuous method generally equipped with analog signal (DC4-20mA) for the continuous measurement output and have a few types to suit for each application.

Please refer to the positioning map below for more details.

Particle counters measure "number of particles in the air (pcs/m3)" and dust monitors measure "particle concentration in the air (mg/m3)".

In case of low dust concentration situation, it is better to use particle counters (pcs/m3) because it's resolution is high and dust concentration value (mg/m3) is too low to use dust monitors.

But on the other hand, particle counter value (pcs/m3) becomes too high and difficult to make judgement in case of high dust concentration.

In this case, it is better convenient to use dust monitors (mg/m3).

Easier way to make judgement whether particle counters or dust monitors should be used is whether the dust concentration to be measured is higher or lower than the concentration level of general office or suburban outdoor.

Dust monitors are better in case it's higher than it.

Particle counters are better if it's lower than it.

In addition, particle counters are single measurement method.

Dust monitors are continuous method generally equipped with analog signal (DC4-20mA) for the continuous measurement output and have a few types to suit for each application.

Please refer to the positioning map below for more details.

Positioning map

Application comparison between particle counters and dust monitors

|

Applications for particle counters |

Applications for dust monitors |

|

① Clean room in semiconductor factories |

① Dust collector leakage monitoring |

|

② Clean room in precision equiment producers |

② Dust generating work place like tunnels, domolition work, factories, etc. |

|

③ Clean room in pharmaceutical, food processing and beverage producers |

③ Welding fume |

|

④ Hospital operating room, etc. |

④ Offices, commercial facilities, etc. |

Generally particle counters are used to monitor cleanliness in the place where cleaner condition (than normal) is required and dust monitors are used to monitor abnormal dust concentration raise in the normal place.

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

Please feel free to contact us if you have any inquiries.

Click here to download documents.

© Matsushima Measure Tech Co., Ltd.