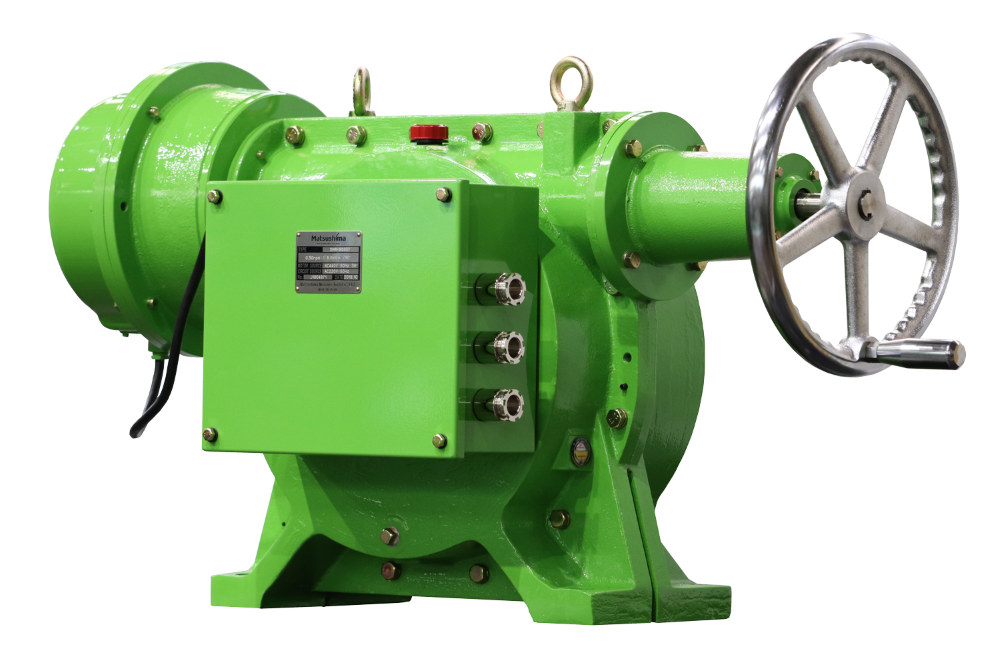

Damper driver

Advantages

-

It can remotely control dampers and machinery even under adverse conditions such as high altitude, high temperature, and dust generation.

- Because of its easy maintenance management and high durability, it has been used for a long time in industrial fields such as iron and steel, cement, nonferrous metals, and electric power. There is a track record of 30 to 40 years of use if overhauled .

\ Download or Request for quote /

Features of Damper Actuator

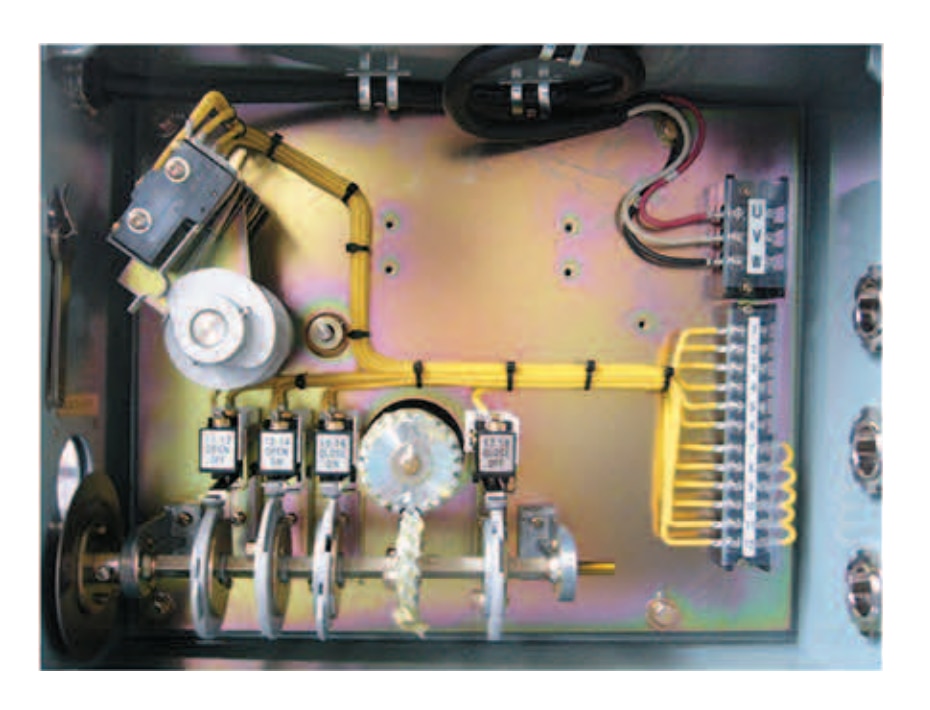

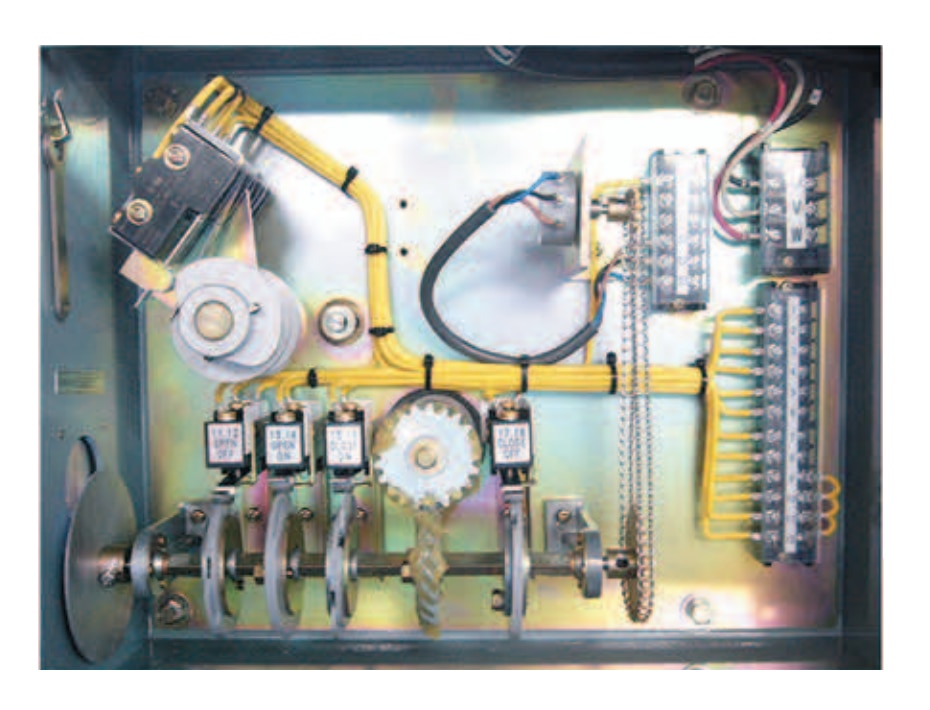

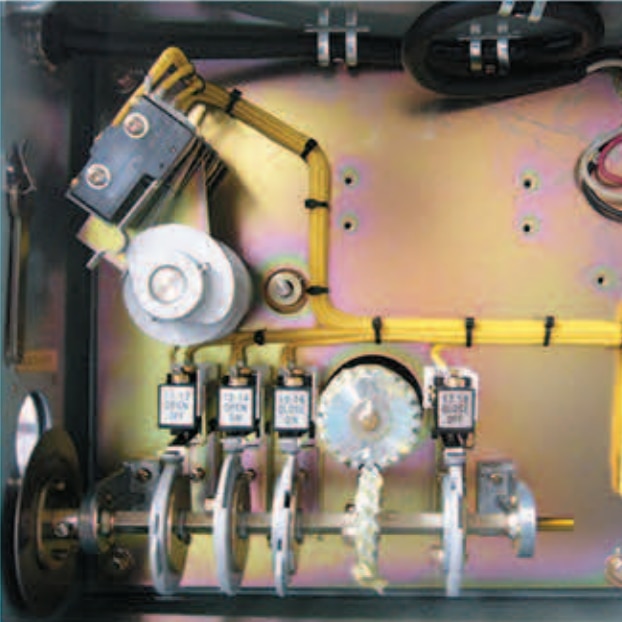

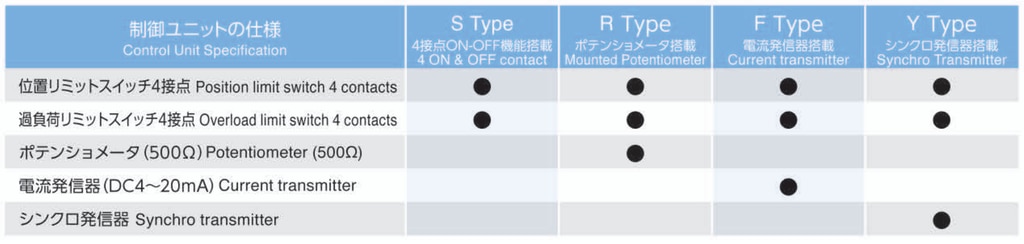

Select from 4 types of control units

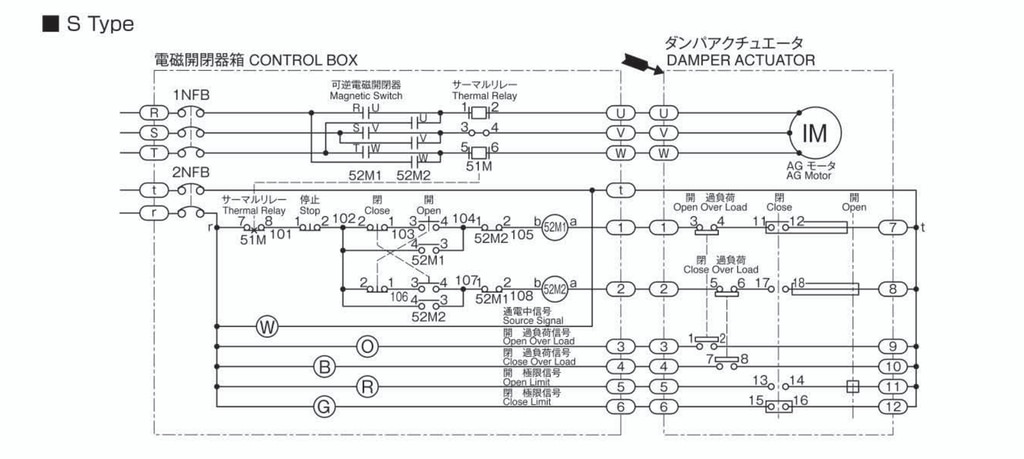

S type

4 ON-OFF contact

function

Position signal: 2 contacts each for fully open and fully closed

Torque signal: 2 contacts each for fully open and fully closed

Opening transmitter: None

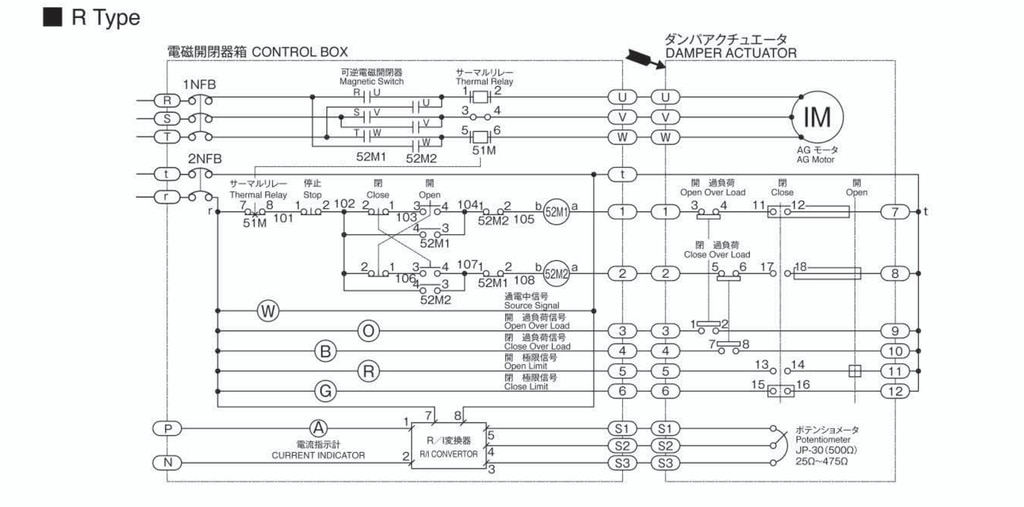

R type

Mounted

Potentiometer

Position signal: 2 contacts each for fully open and fully closed

Torque signal: 2 contacts each for fully open and fully closed

Opening transmitter: Potentiometer

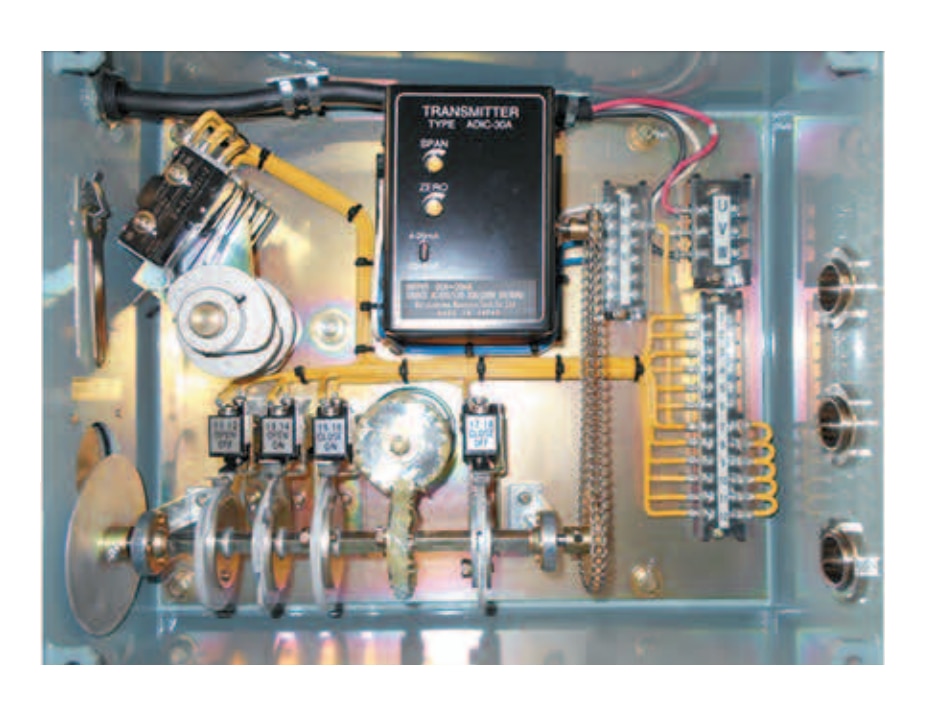

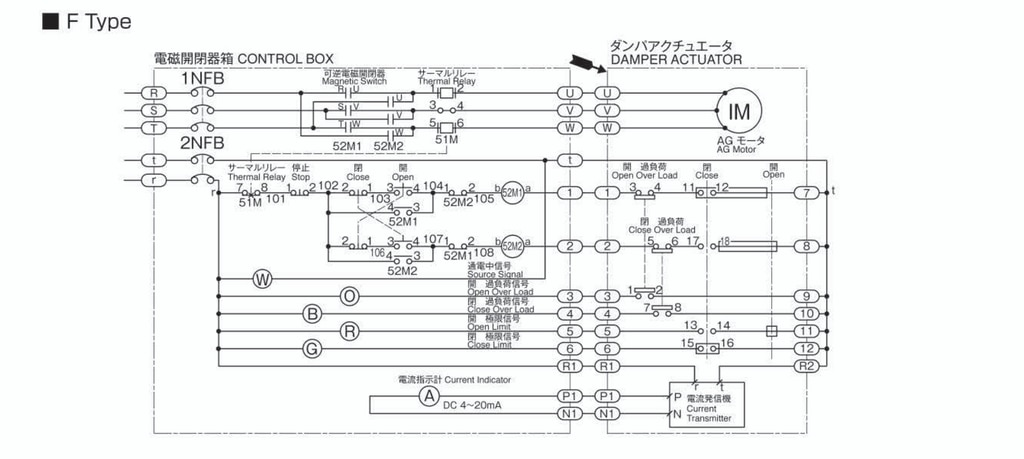

F type

Current Transmitter

Position signal: 2 contacts each for fully open and fully closed

Torque signal: 2 contacts each for fully open and fully closed

Opening transmitter: Current transmitter

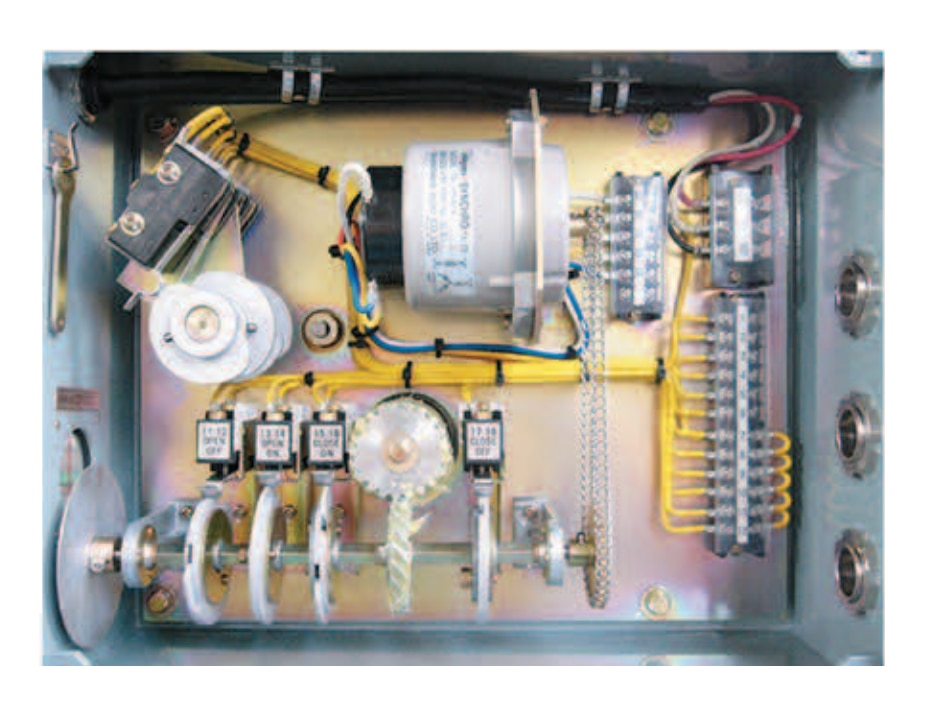

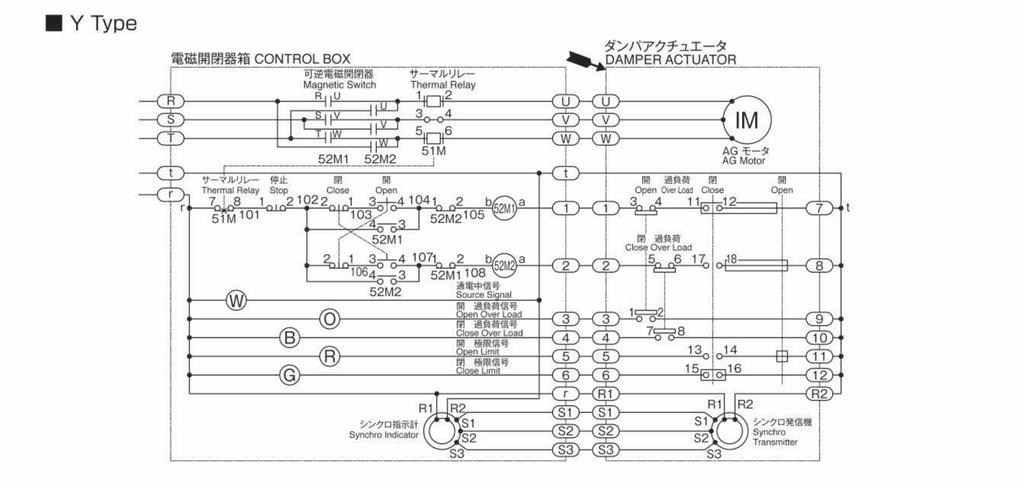

Y type

Synchro transmitter

Position signal: 2 contacts each for fully open and fully closed

Torque signal: 2 contacts each for fully open and fully closed

Opening transmitter: Synchro transmitter

◉Options

We also manufacture a model with a built-in inverter positioner that automatically operates based on the customer's opening command (4 to 20 mA DC). (Output torque 200N・m to 4000N・m limited)

Please consult us separately.

Other features

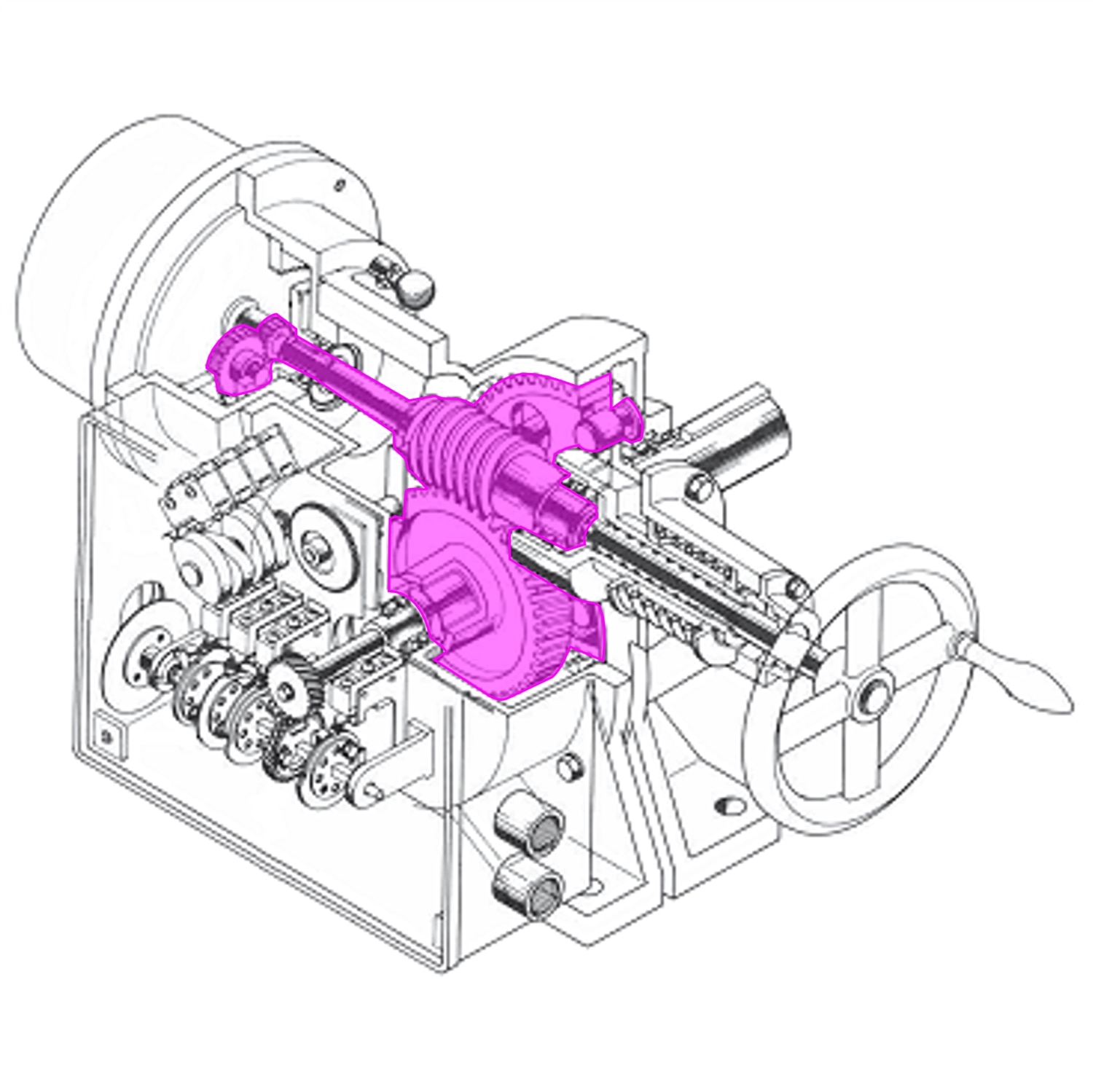

High reduction ratio

The reducer is a compact actuator that is composed of three types of reduction mechanisms: planetary gears, worm gears, and eccentric gears, achieving a reduction ratio of approximately 1/3600.

Equipped with overload detection mechanism as standard

Safe design that detects overload torque and stops the motor before it is damaged.

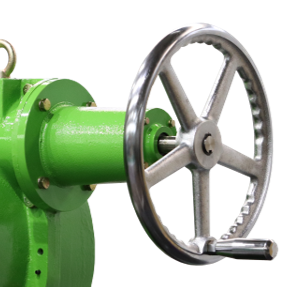

Equipped with manual handle as standard

Even in emergencies where electricity cannot be supplied, such as power outage, the damper can be moved and controlled using the included manual handle.

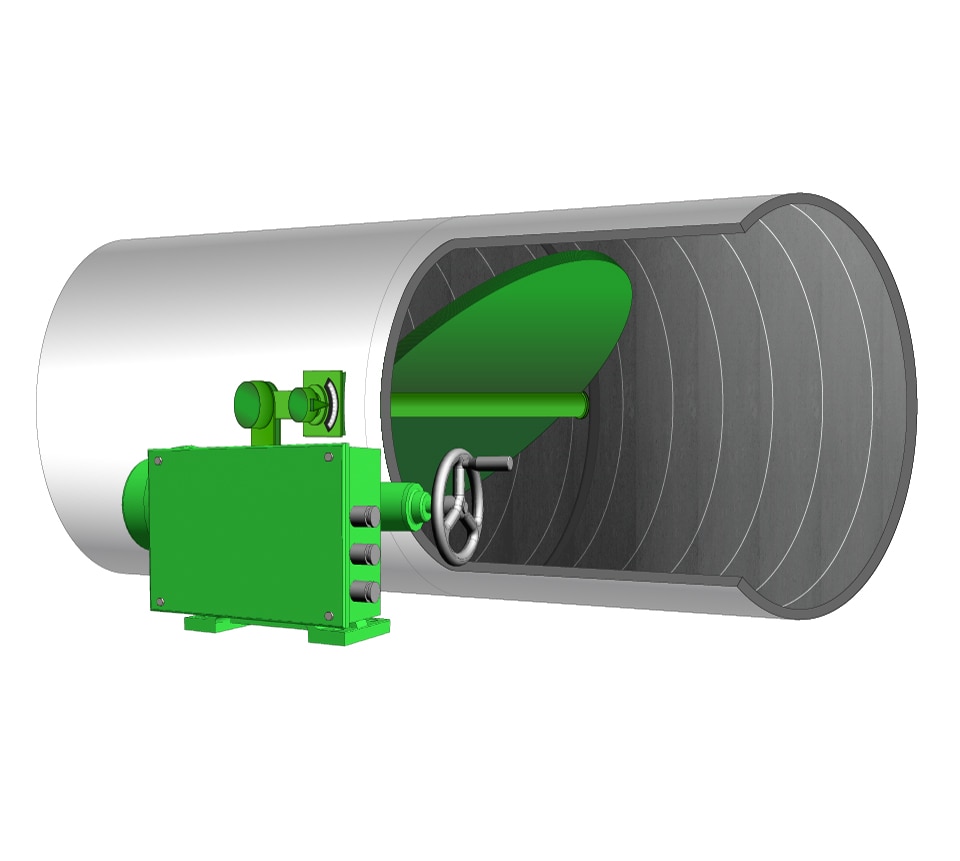

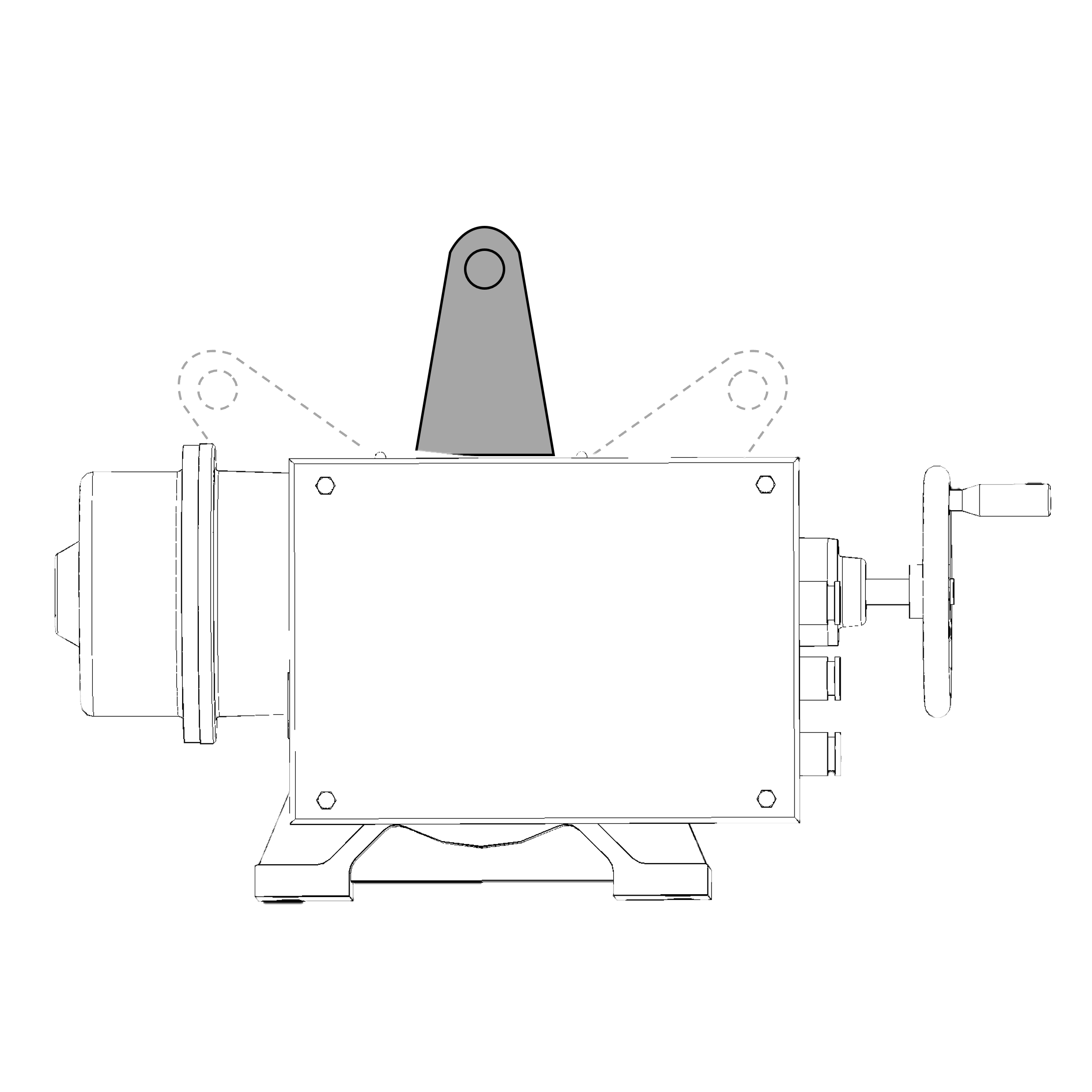

Operating principle

The motor's power is reduced to approximately 1/3600 by a reducer, producing a large torque that moves damper.

When damper reaches fully open or fully closed position, built-in limit switch automatically stops the motor.

It is also possible to install a transmitter. You can check the opening status in real time.

How to use?

1.Determine

mounting position

Due to restrictions on heat resistance of operating motor, control equipment, lubricating oil, etc., ambient temperature should

preferably be 40°C or less, and should not exceed 45°C at the most.

2. Mounting

When connecting output shaft and load shaft, align and install them so that midpoint of their operating angles match.

Turn manual handle so that indication on indicator scale plate is at 45 degrees, and then connect when it matches middle position of load shaft.

3. Wiring

Please check interconnection diagram and wiring diagram of panel before wiring.

4. Adjustment

After checking wiring, check motor rotation direction so that it can be stopped at any time. Cam is adjusted before shipping, but adjustments are required if the cam is fully open or fully closed or if transmitter position is not correct. Please adjust according to instruction manual.

*Please see the instruction manual for details.

\ Download or Request for quote /

Maintenance

Regular maintenance recommended

The damper actuator has several lubrication points, so please lubricate it regularly.

Please refer to instruction manual for the types and timing of lubrication and lubrication.

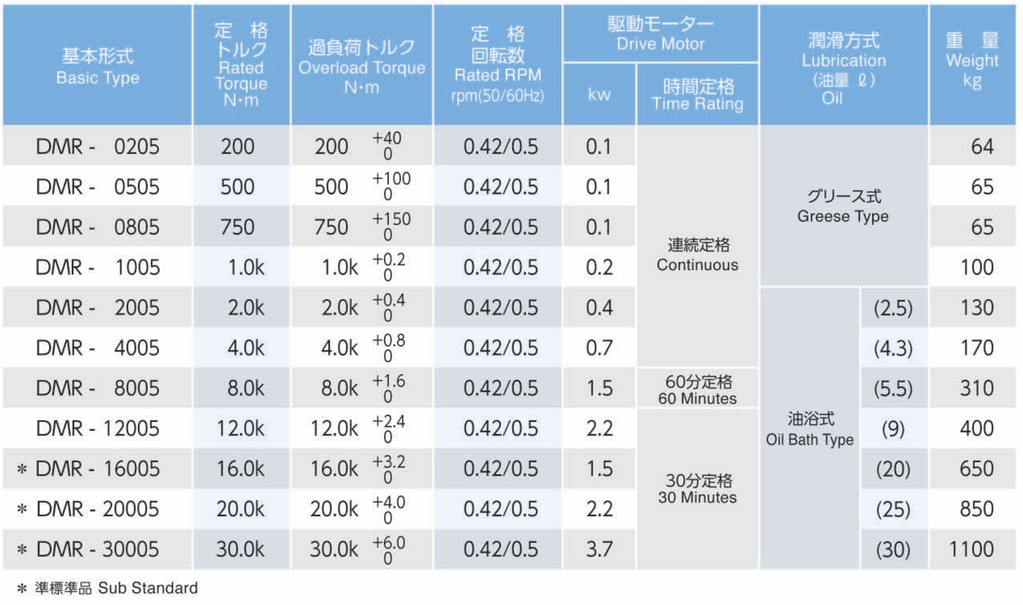

Model lineup

Specificatios

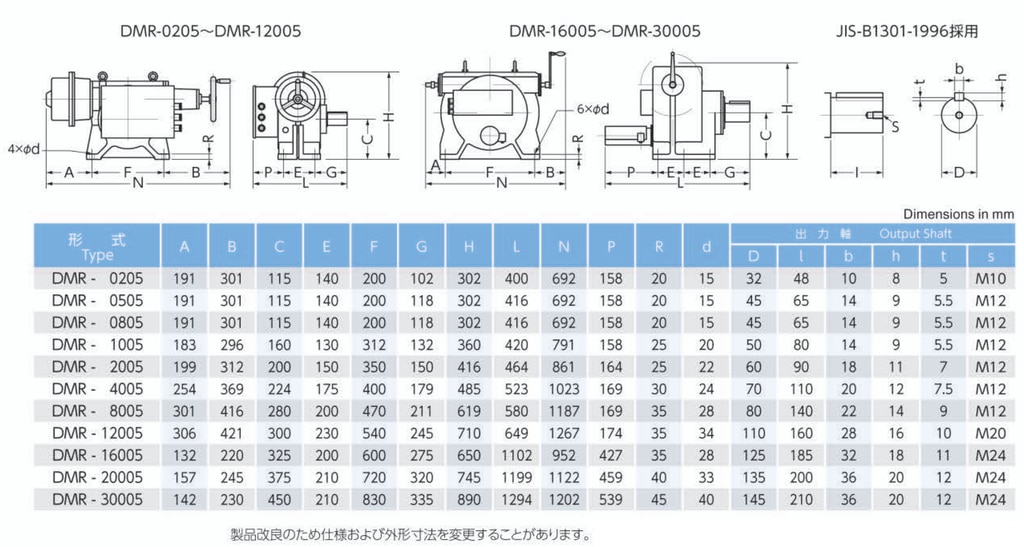

Dimensions

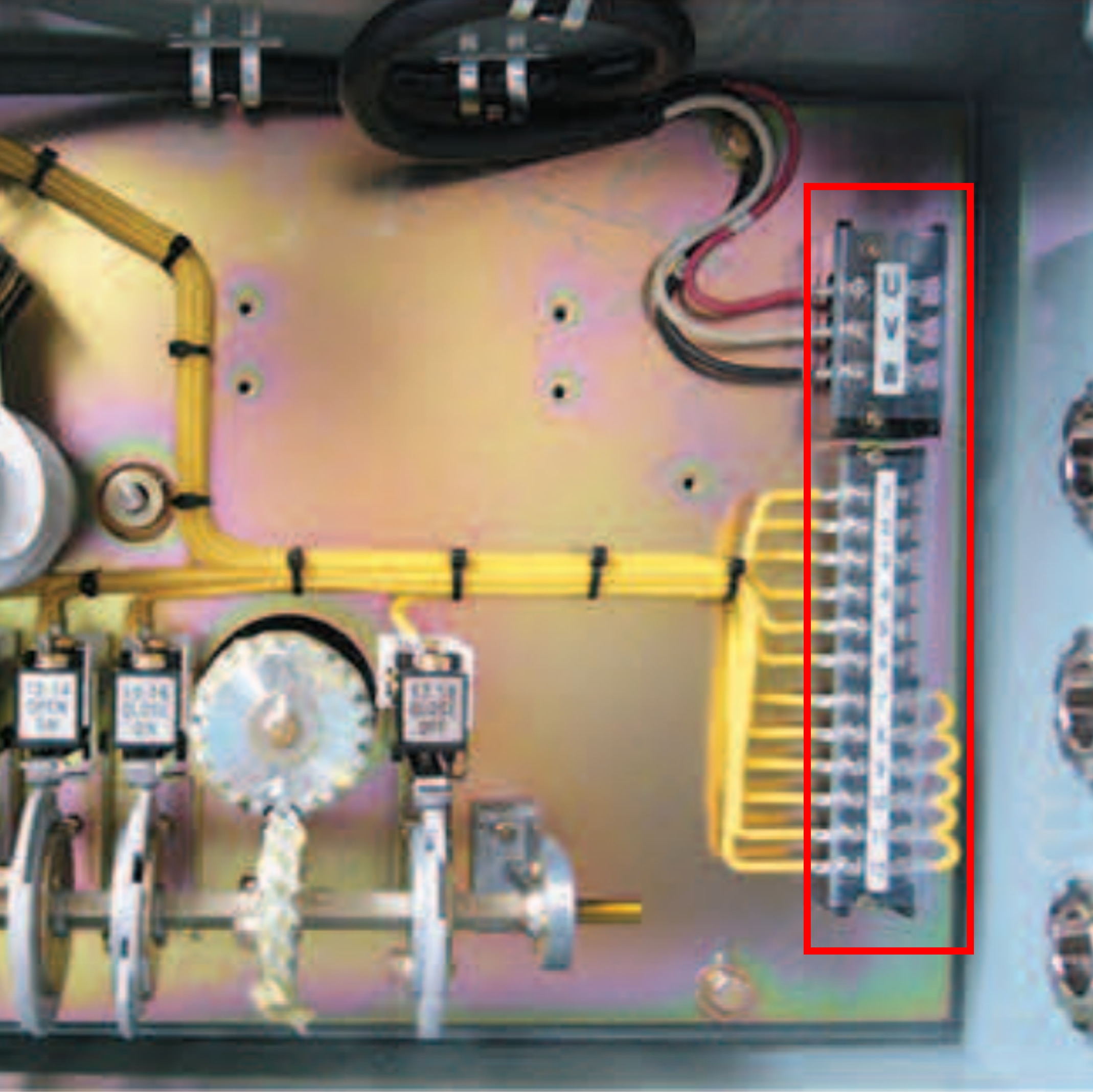

Connection diagram

S type: 4 ON-OFF contact function

R type: Mounted Potentiometer

F type: Current Transmitter

Y type: Synchro transmitter

\ Downloar or Request for quote /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.