Powder Measuring Instrument

Air Particle Monitor continuously monitors the number and mass concentration of fine particles such as dust, aerosols floating in space.

It is ideal for managing manufacturing and working environments such as precision work rooms and clean booths.

Advantages

\ Download or Request for quote /

Features of Air Particle Monitor

Air Particle Monitor adopts the light scattering method. Its main features are:

24-hour monitoring

on behalf of people

Never miss

a microparticle!

Continuous measurement with high sensitivity of 35 to 1,000 μg/m3 does not miss even the slightest intrusion of microparticles. Continuous measurement of cleanliness is also possible and functions as a class 10000 particle counter.

Labor saving by

controlling the cleaning device with external

output

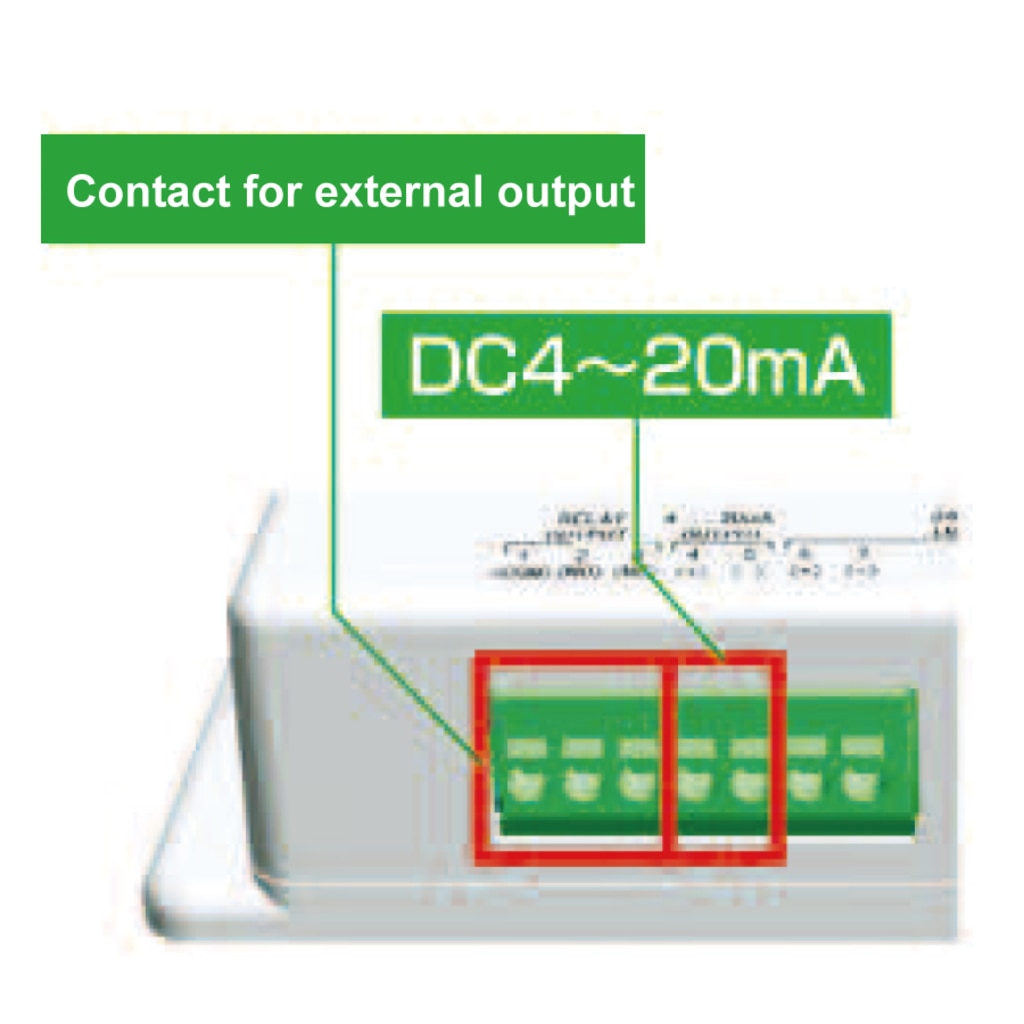

Equipped with analog output (4 to 20mA DC) and contact signal (1c). It monitors dust concentration trends and detects abnormalities. Also, if this signal is used to control the operation of the purifier, an energy saving effect can be expected.

Ascertain the situation

anytime, anywhere using a PC or smartphone from a remote location

Equipped with Wi-Fi function. Measured values and abnormalities can be checked at any time on a PC or smartphone from a remote location. Labor saving is achieved without the need for on-site confirmation and on-site measurement.

Operating principle

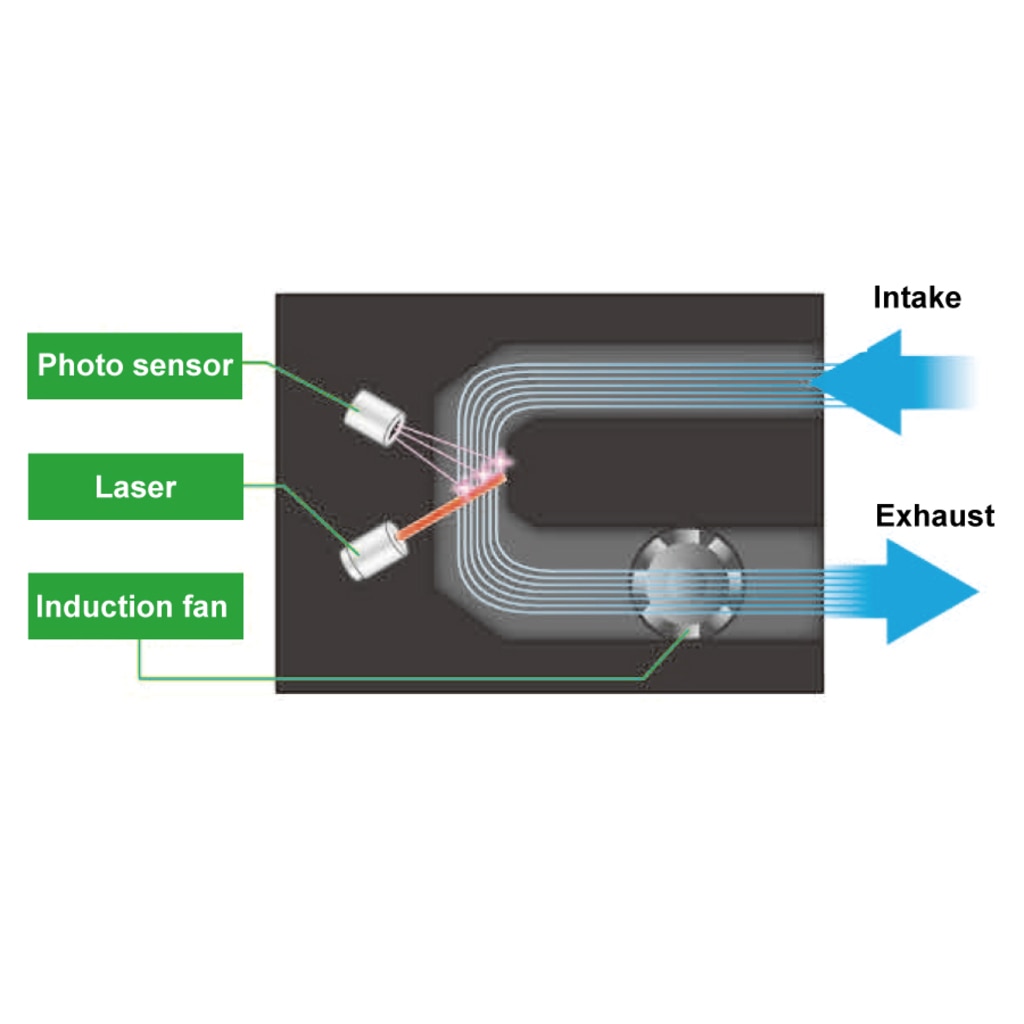

Air Particle Monitor uses a light scattering method.

For example, if you illuminate the darkness with a flashlight, you can see dust floating in the space. This is because the light emitted from the flashlight hits dust in the air and the scattered light reaches your eyes. This is the basic principle of the light scattering method.

By using a laser diode instead of a flashlight and a photodiode that receives specific light instead of a human eye, the light scattered from dust is converted into electrical signals to measure the concentration and number of fine particles.

In addition, an induction fan is installed in order to take in floating microparticles into the sensor.

\ Download or Request for quote /

How to use?

1. Select

installation

location

Decide where you want to monitor airborne particles in your room. It is best near where particulate originates or flows. And please secure the power supply.

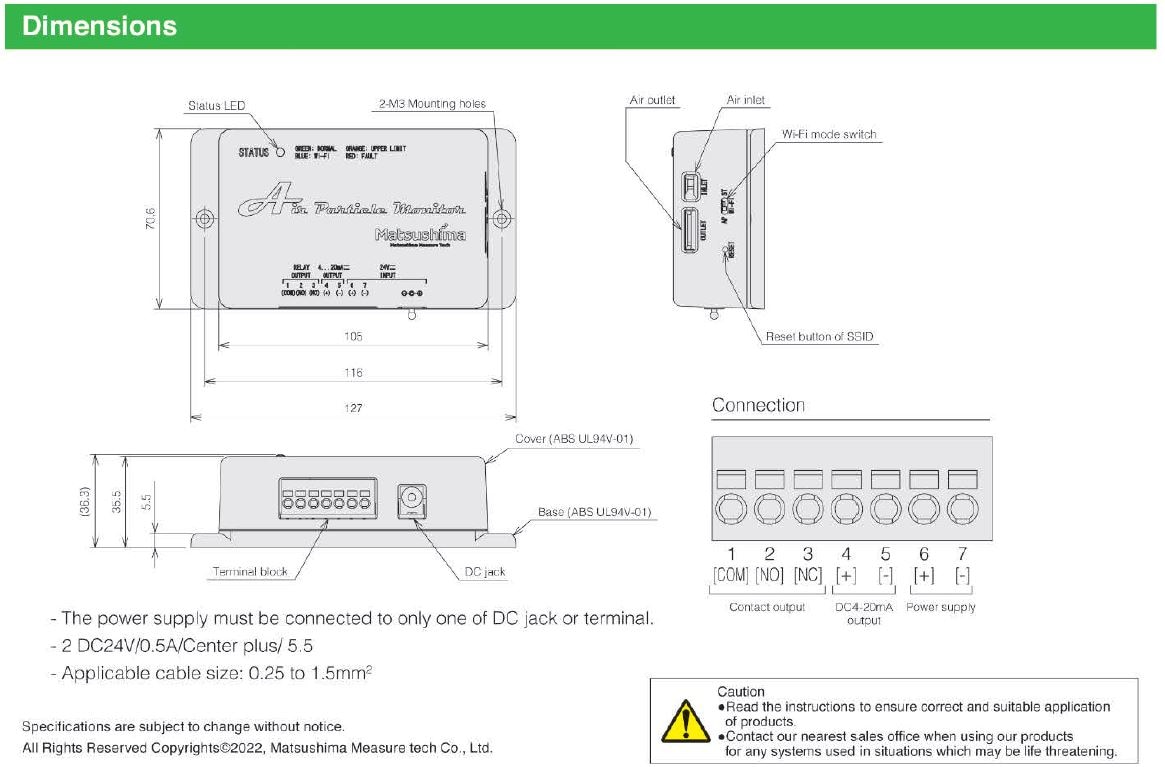

2. Installation

Since it uses Wi-Fi, install it in an environment with good visibility and few obstacles. Check the top and bottom of the main unit and point the suction port in the direction where fine particles are generated.

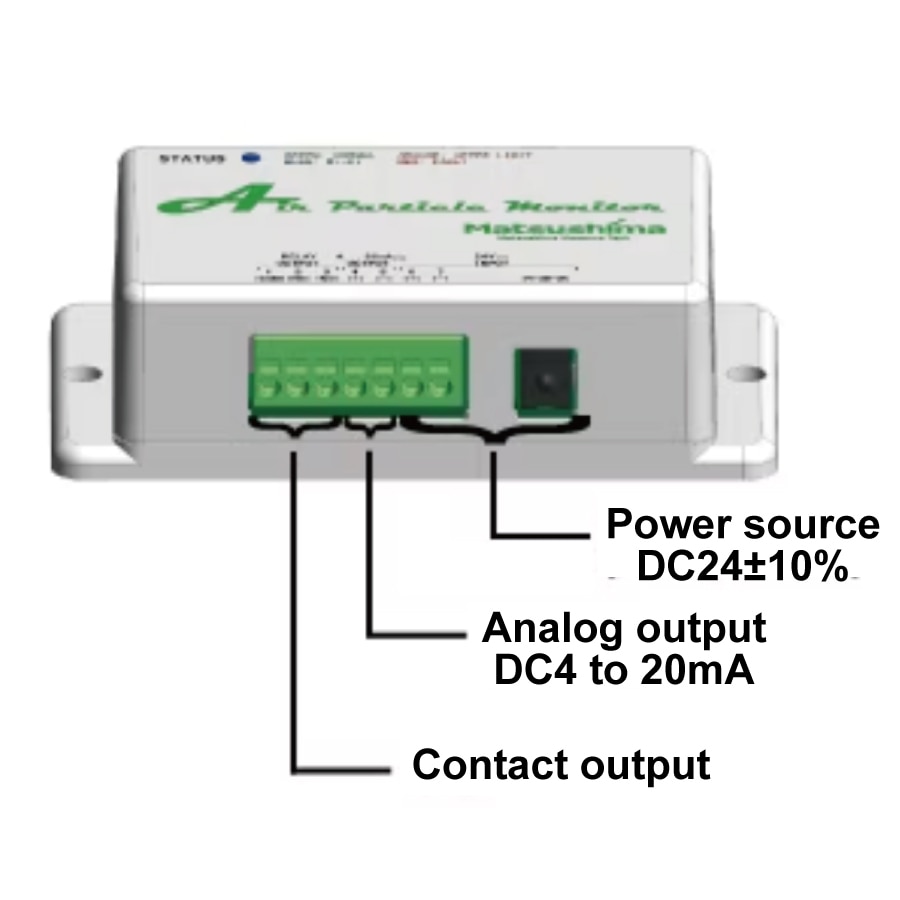

3. Wiring

Wire the power supply and, if necessary, the analog output and contact output. An optional power jack allows connection to an electrical outlet.

4. Settings

Connect your PC or smartphone to the main unit using Wi-Fi. Access from a PC or smartphone browser to check and set measurements.

\ Download or Request for quote /

Maintenance

If you use it for a long time, you may be concerned about the soundness of the air particle monitor.

We designs products with maintenance in mind.

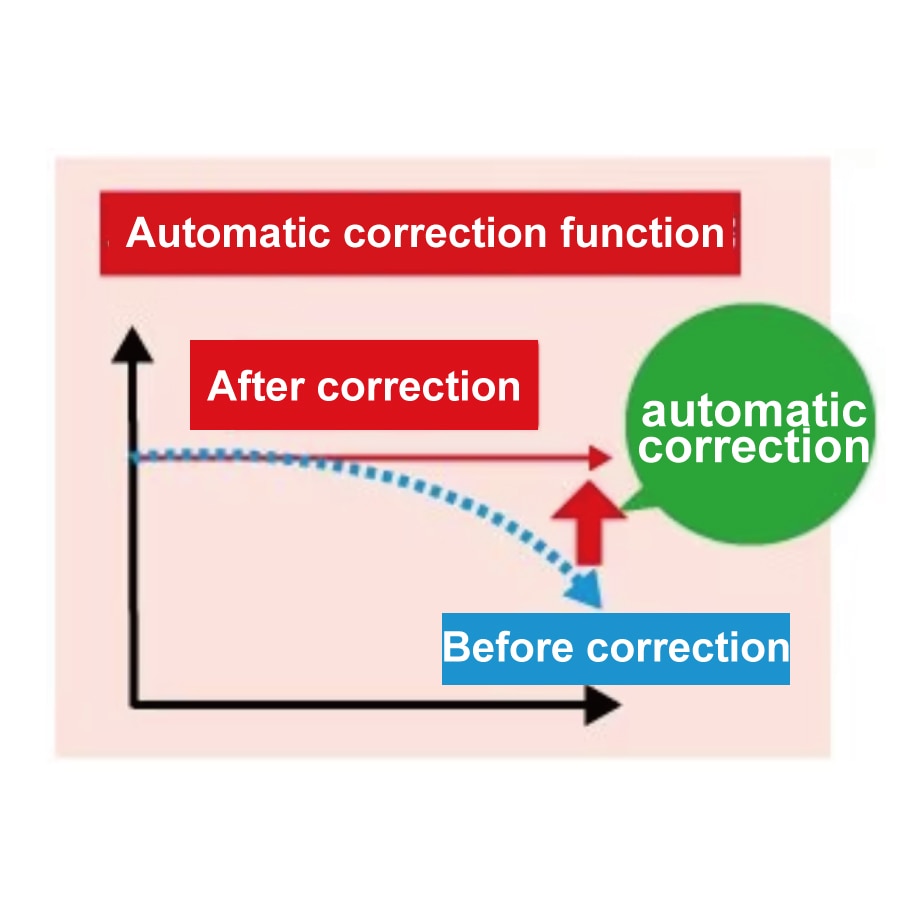

Auto-calibration function

Long term stability

As the usage time increases, the measurement performance such as laser output, light receiving sensitivity, and suction power will decrease. The auto-calibration function is a function that detects this and automatically corrects it. Realizes long-term stable measurement.

Maintenance-free

Maintenance-free with the auto-calibration function. Please replace it regularly according to the service life.

*The estimated useful life is 5 years for continuous measurement.

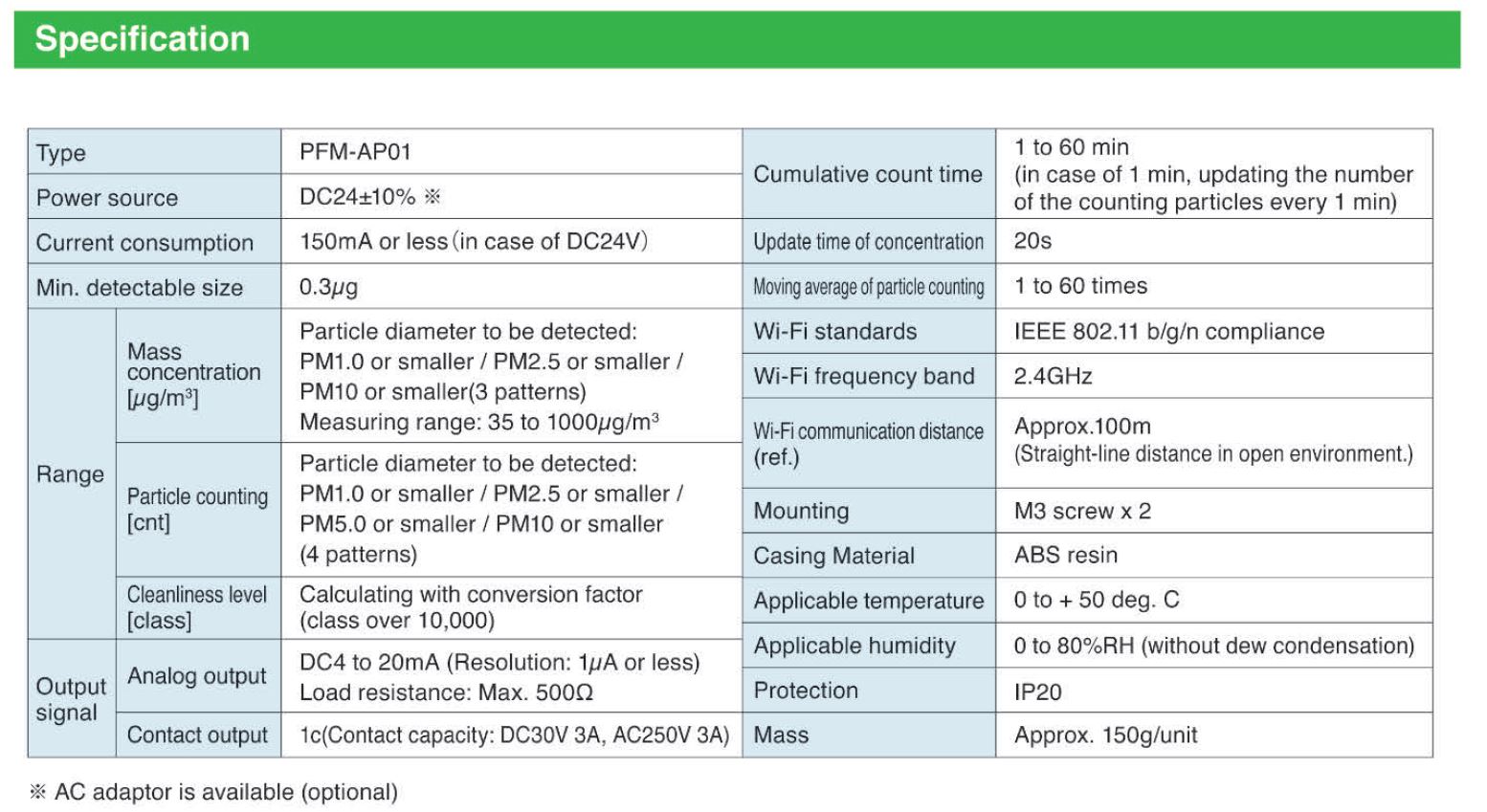

Specifications

\ Download or Request for quote /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.