Position Detector

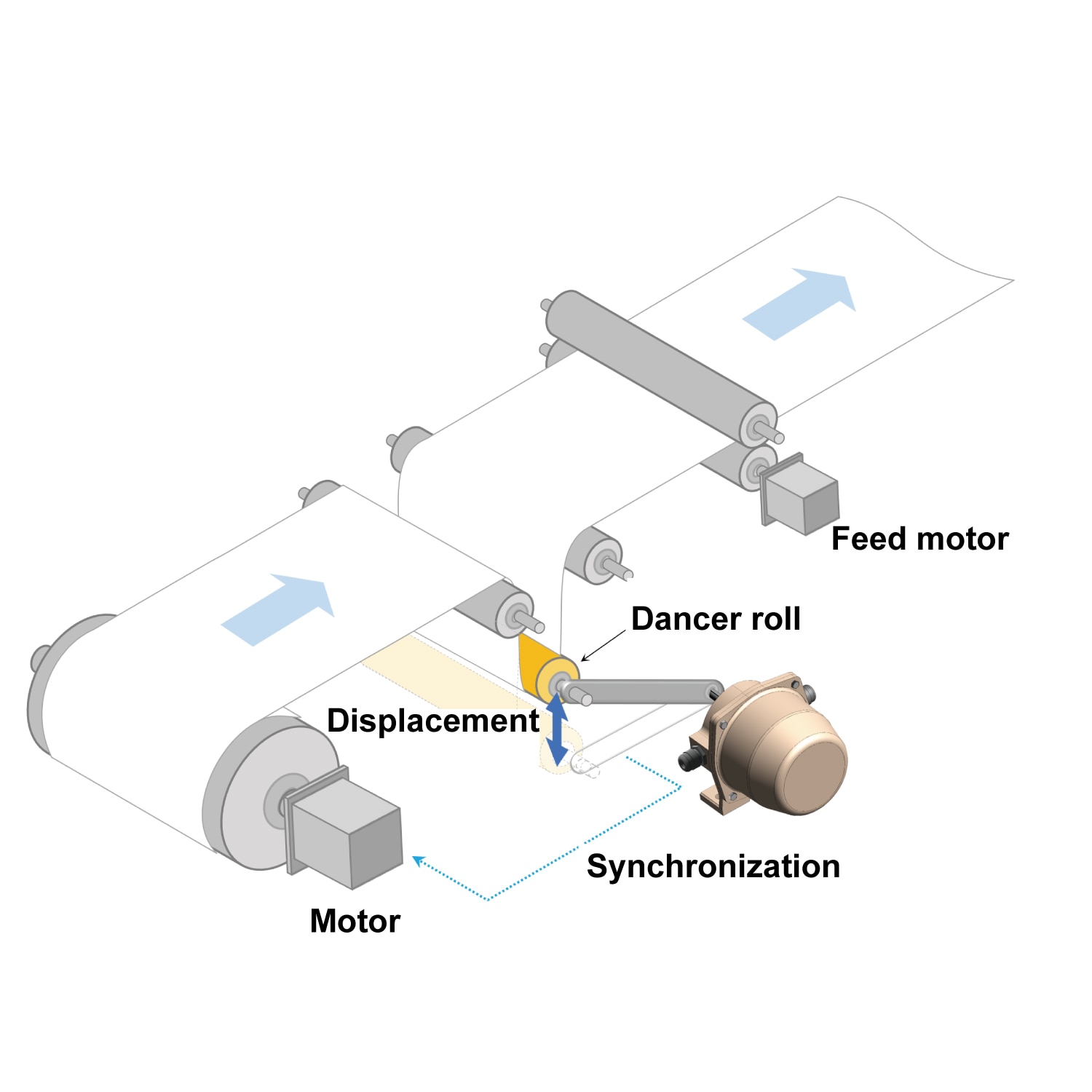

Displacement detectors are mainly used in paper mills as displacement detectors for dancer rolls that are used to control the speed of winders. The synchro transmitter is housed in an indoor dustproof case for excellent durability.

Advantage

Real-time control is possible because Displacement Detector can be mechanically detected in accordance with movement of dancer roll and directly output as a voltage signal.

\ Download or Request for quote /

Features of Displacement Detector

Displacement Detector

Model YVGC-500W

Pressure-resistant explosion-proof Displacement Detector

Model YVGCM-790

Resistant to noise

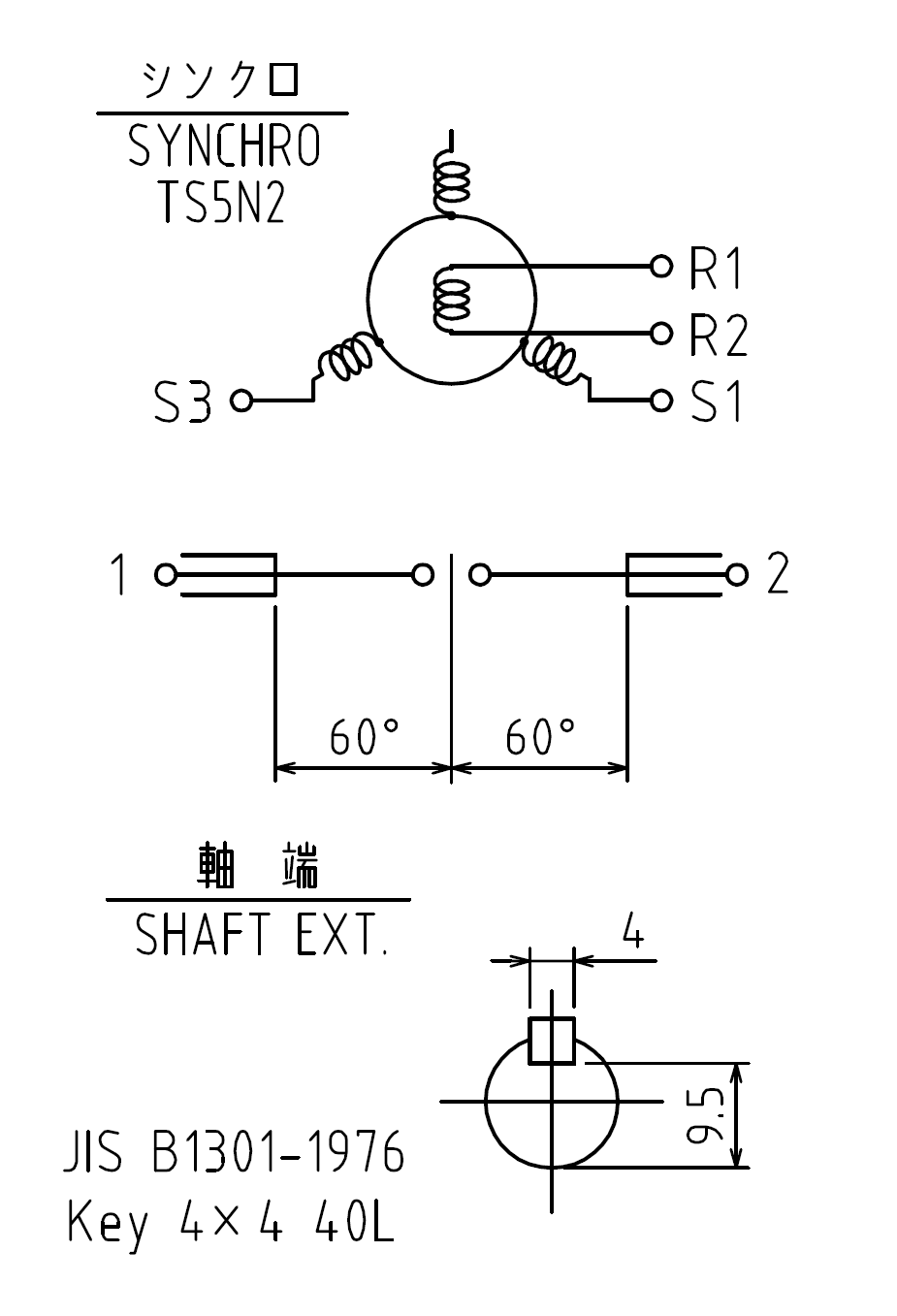

It has a built-in synchro oscillator and its output voltage is as high as ±82V, so it is difficult to be affected by electrical disturbances and wiring work is easy. Usable displacement angle is ±60deg.

A pointer is provided on the input shaft so that amount of displacement can be confirmed visually.

Equipped with ultimate limit

In addition to synchronous motor, it incorporates a microswitch for extreme contact signals.

Explosion proof

We also manufacture pressure-resistant explosion-proof specifications (d2G4) for explosion-proof areas.

*For details, see the catalog and instruction manual.

Operating principle

Displacement Detector is a mechanical shaft Displacement Detection sensor that incorporates a synchro transmitter and a limit switch for detecting both ends.

The amount of displacement of the machine shaft is detected by rotation angle of the synchro transmitter and output as a change in AC voltage, so signals can be transmitted without being affected by noise.

Maintenance

Please carry out regular inspections.

If a large amount of dust accumulates around Displacement Detector, clean it regularly.

Check that there are no loose screws in the installation part or shaft connection part. Make sure that cover bolts are securely closed. If even one part is loose, dust and moisture can enter and cause malfunction.

Model lineup

Specifications

|

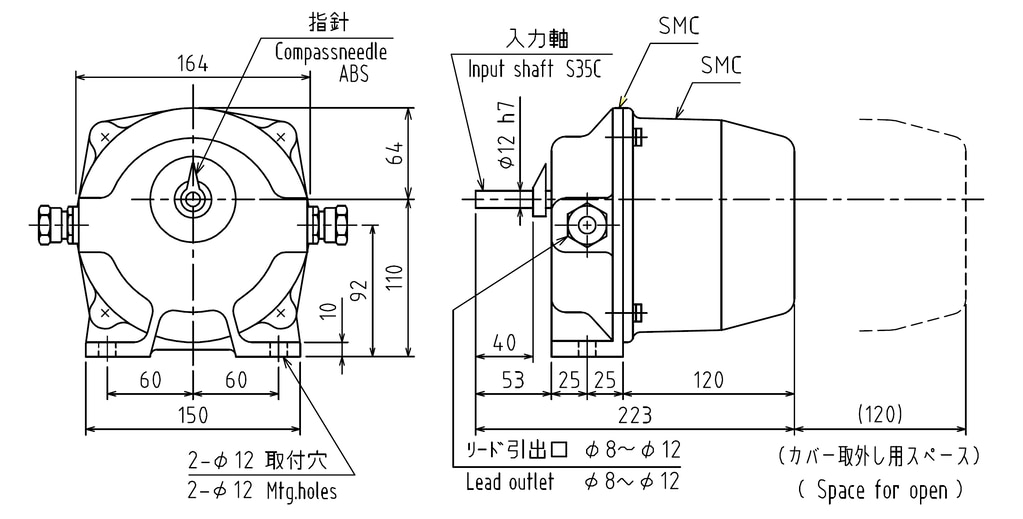

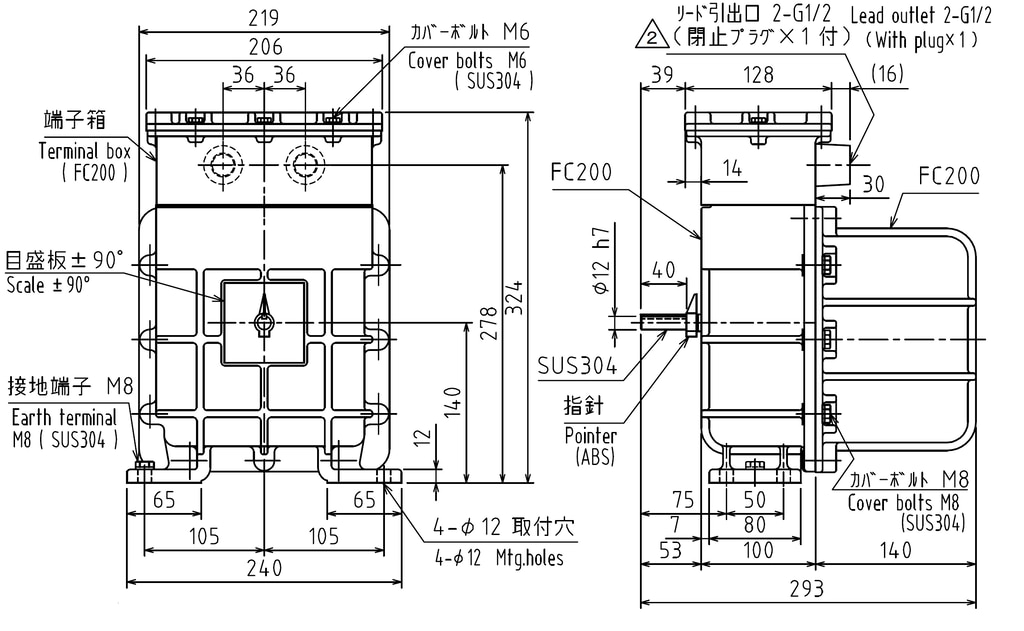

Dimension Diagram

Model YVGC-500W

Model YVGCM-790

Connection diagram

\ Download or Request for quote /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.