Position Detector

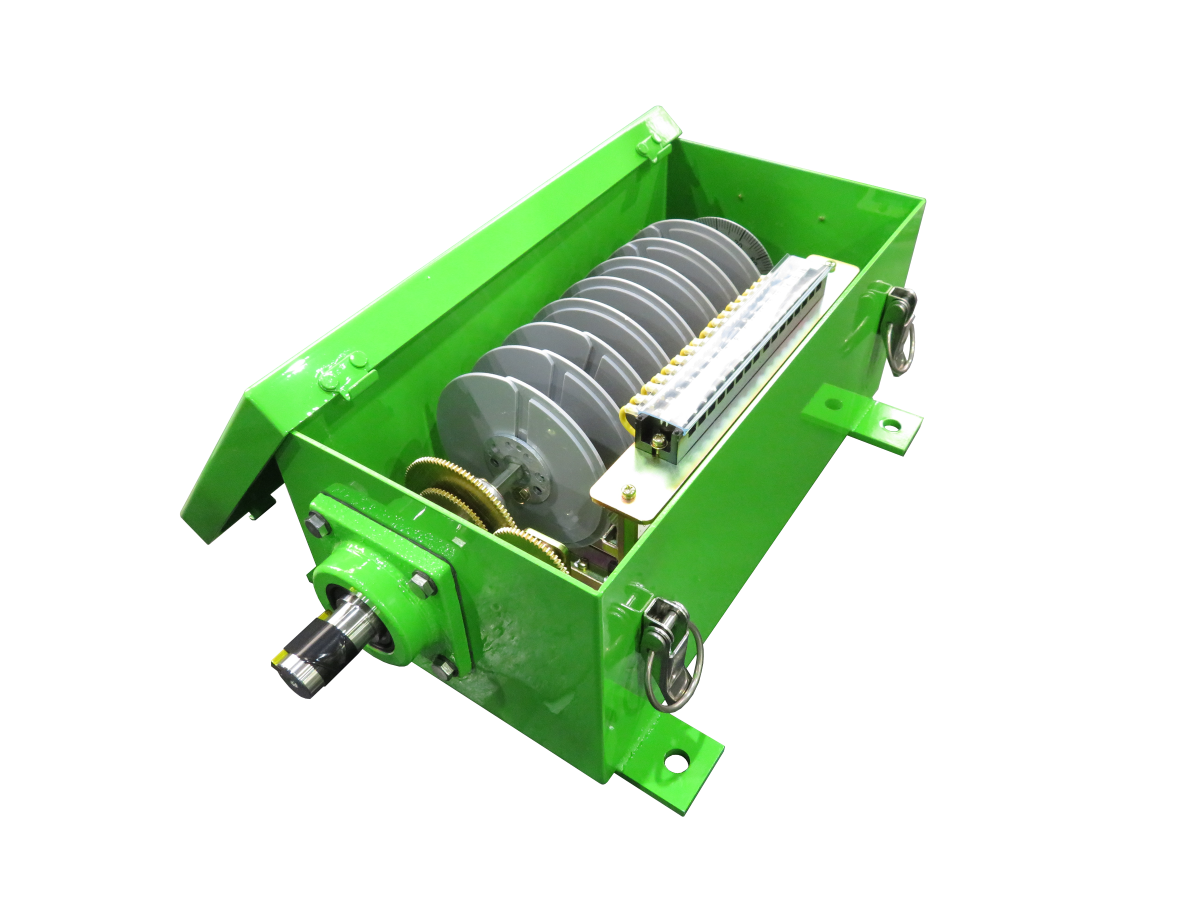

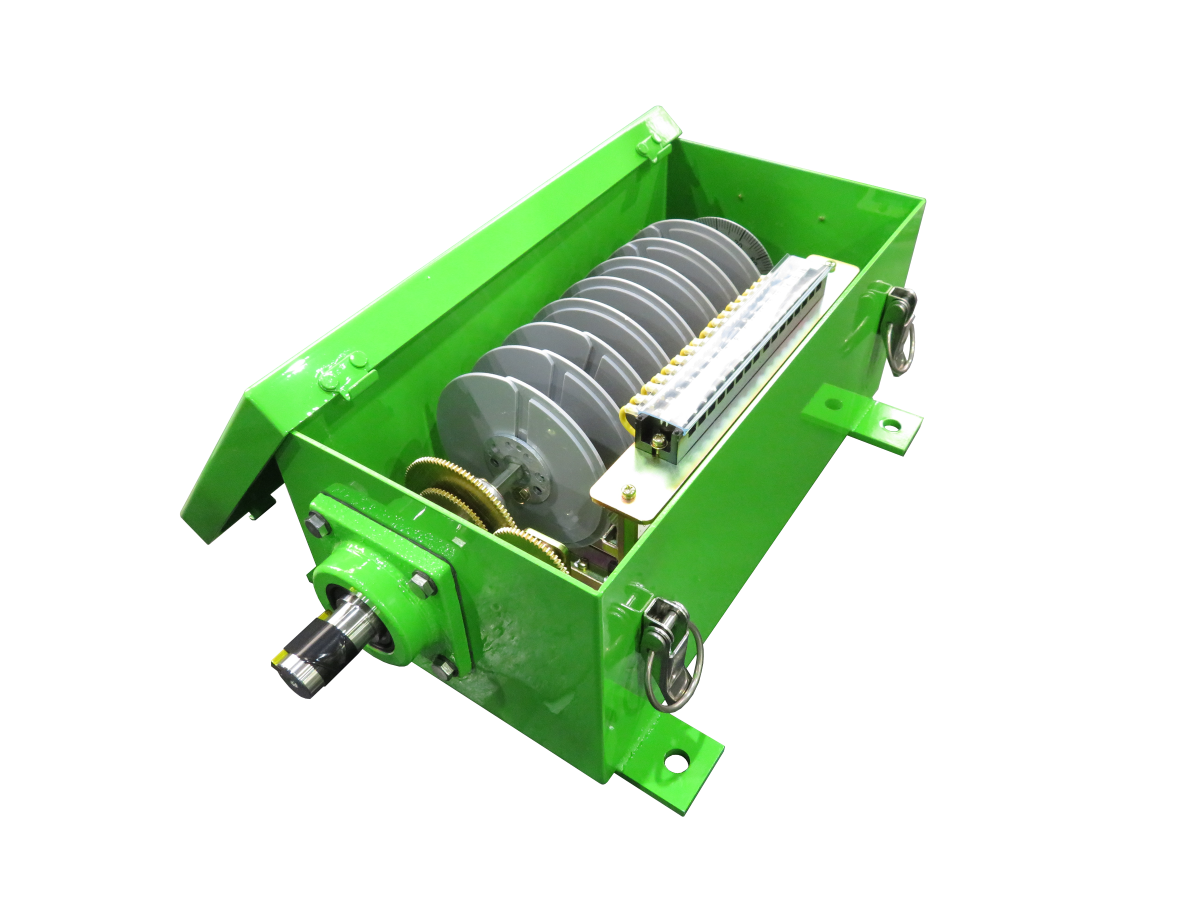

Drum Type Limit Switch is multi-contact output type limit switch.

It is widely used for positioning control of machinery used in many industrial production lines, such as cranes, unloaders, stackers, reclaimers, mobile trippers, and swivel chutes.

We also accept customization according to needs of site, such as input method, number of contacts, detection accuracy, presence or absence of transmitter.

Advantages

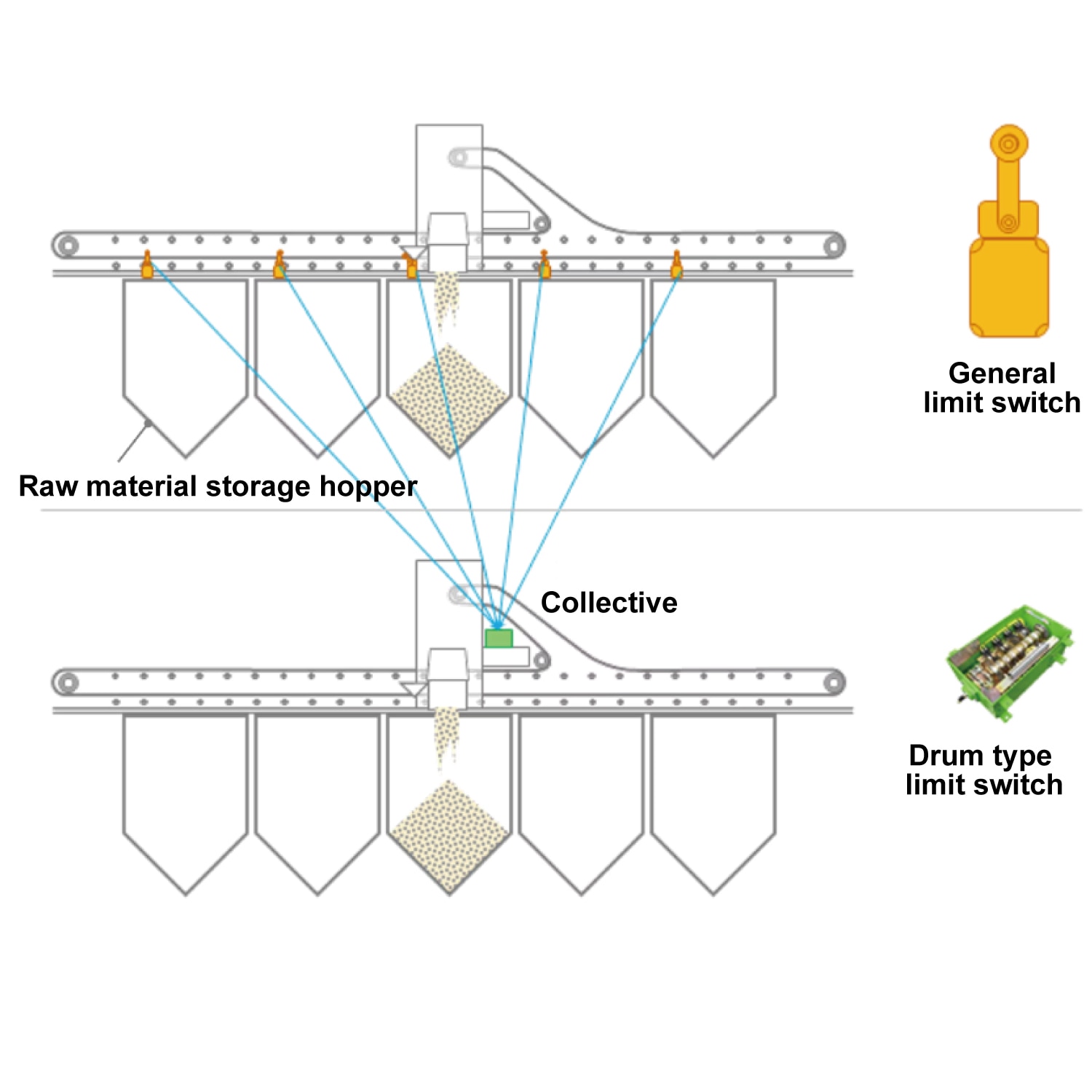

Since one unit can output many contact signals, space and wiring can be saved.

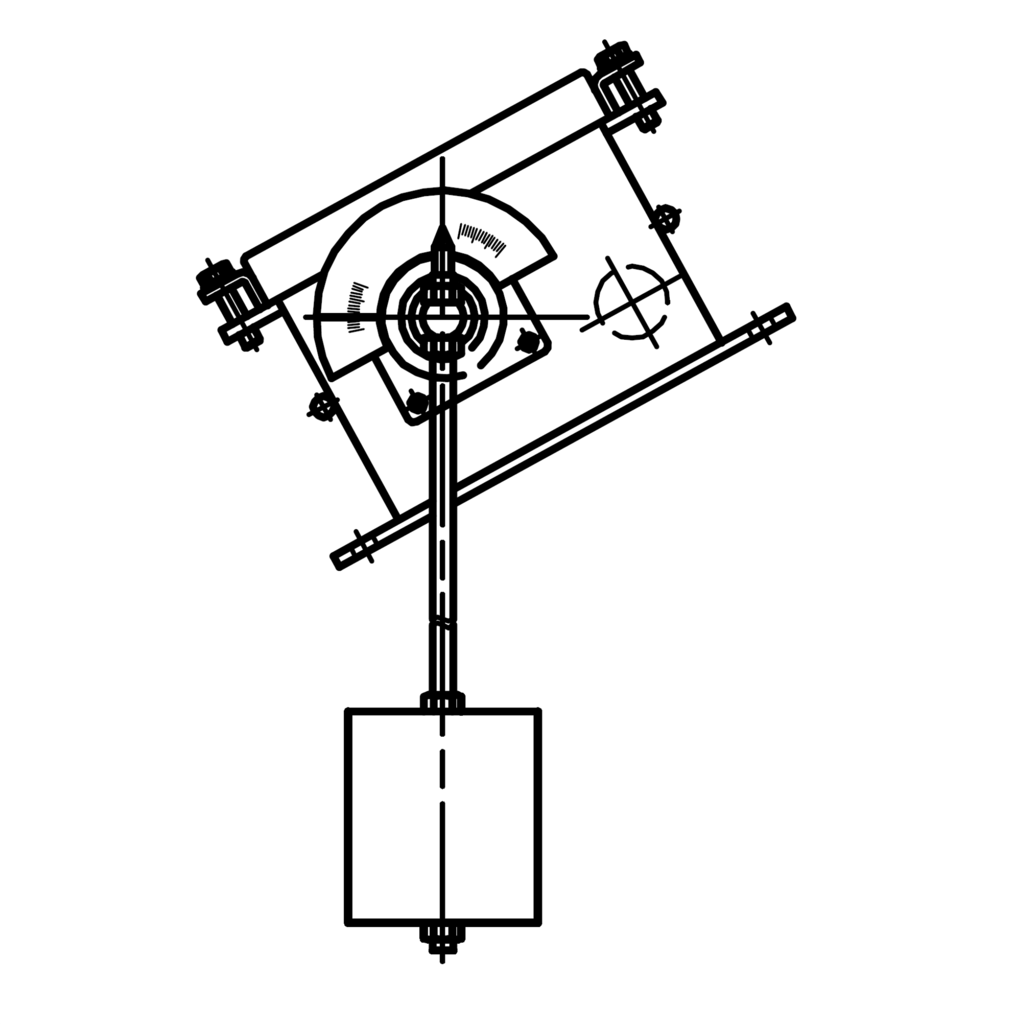

For example, if you use a general limit switch for a mobile tripper as shown in the left figure, you have to place a limit switch on each hopper and wire it to each. Also, when fine-tuning, if the position of the limit switch is bad, you will have to change mounting position in the worst case.

Consolidating these into a Drum Type Limit Switch can save space, reduce wiring, and increase flexibility of adjustment.

\ Download or Request for quote /

Features of Drum Type Limit Switch

Large cam for easy

adjustment

Cam diameter is as large as Φ110mm (standard type), making it easy to adjust.

Plenty of options

- Available from 4 contacts. We have a track record of up to 26 contacts.

- Easy reset with zero point adjustment mechanism.

- Built-in switch can be selected from microswitch (reed contact), reed switch, and proximity switch.

- If backlashless gears are used, further accuracy improvement can be expected.

Customizable

- We design and manufacture the gear ratio according to input rotation angle. Maximum reduction ratio of 1/100 is possible.

- It is also possible to incorporate a transmitter such as a synchro or encoder.

- It is also possible to detect tilt angle by hanging weight on input shaft.

*For details, please refer to the instruction manual.

Operating

principle

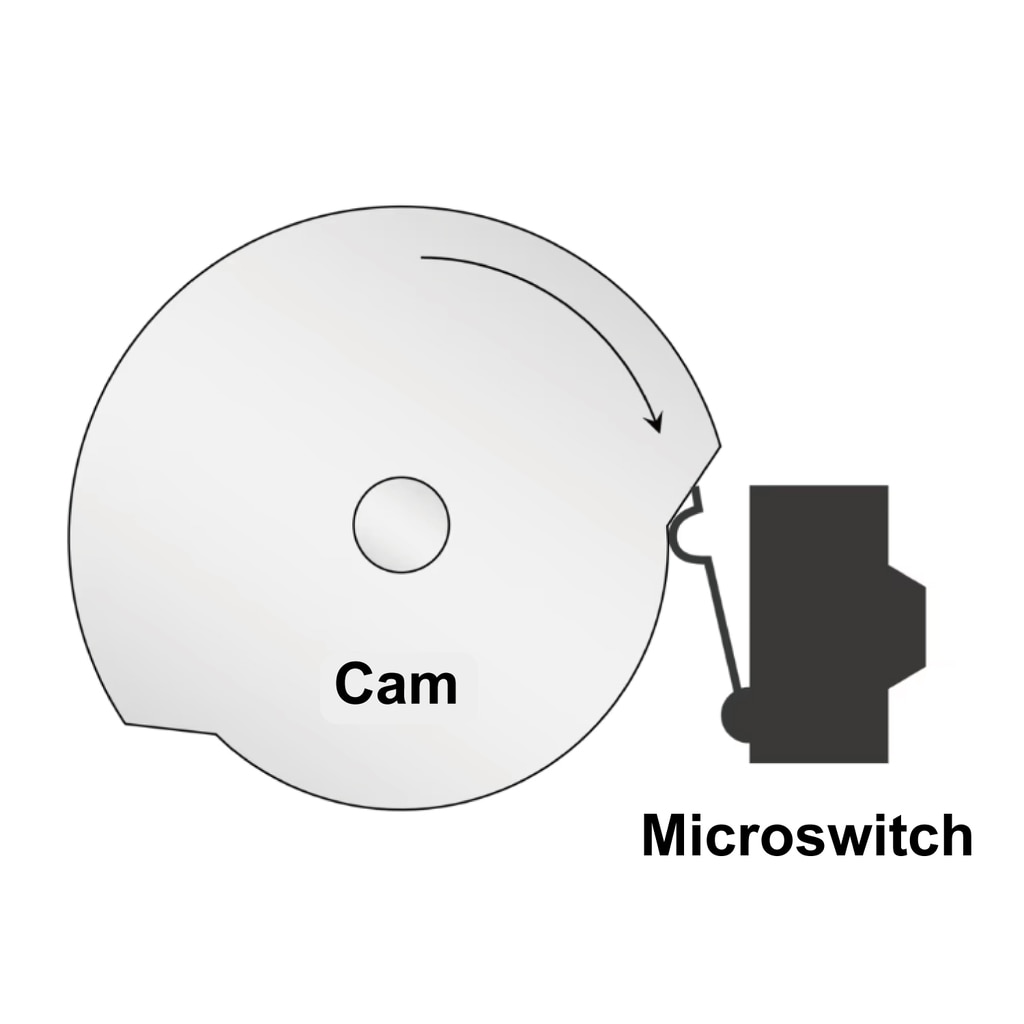

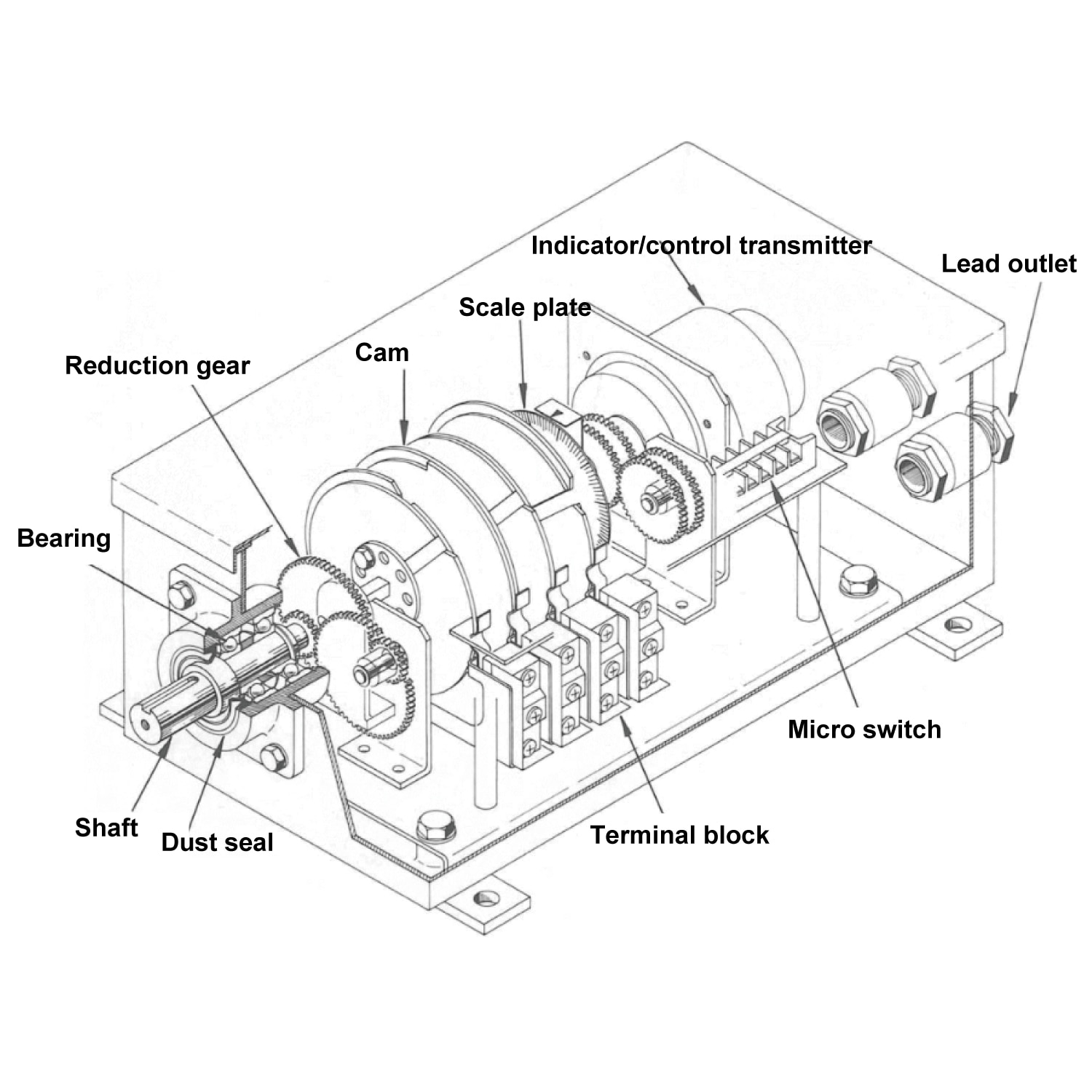

It mainly consists of input shaft, speed reducer, cam and micro switch.

When the shaft takes in number of rotations from equipment, unevenness of multiple cams turns on/off each microswitch and outputs a contact signal as position information.

How to use?

1.Determine

mounting position

There is no problem with normal vibrations caused by the operation of general motors and speed reducers, but large vibrations can cause malfunctions. Do not install near sources of large vibrations, such as vibrating screens or vibrating feeders.

2. Mounting

As a general rule, install the equipment horizontally. When attaching a sprocket or coupling to input shaft, forcing it into place and applying strong impact may cause damage to bearings and gears.

When connecting input shaft with a gear or chain, do not apply a strong load to the input shaft.

3. Wiring

Perform wiring while checking cam configuration diagram on the delivery drawing.

After wiring, securely tighten the waterproof connector.

4. Adjustment

Since it is basically adjusted at the time of shipment from the factory, there is no need for readjustment at time of installation. However, when making fine adjustments, please follow the instructions in the instruction manual.

*For details, please refer to the instruction manual.

Maintenance

Please carry out regular inspections.

- If a large amount of dust accumulates around Drum Type Limit Switch, clean it.

- Check there are no loose bolts or screws in installation section or shaft connection section.

- Apply general grease to internal gears about once every three months.

- Also lubricate the oil seal of input shaft.

\ Download or Request for quote /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.