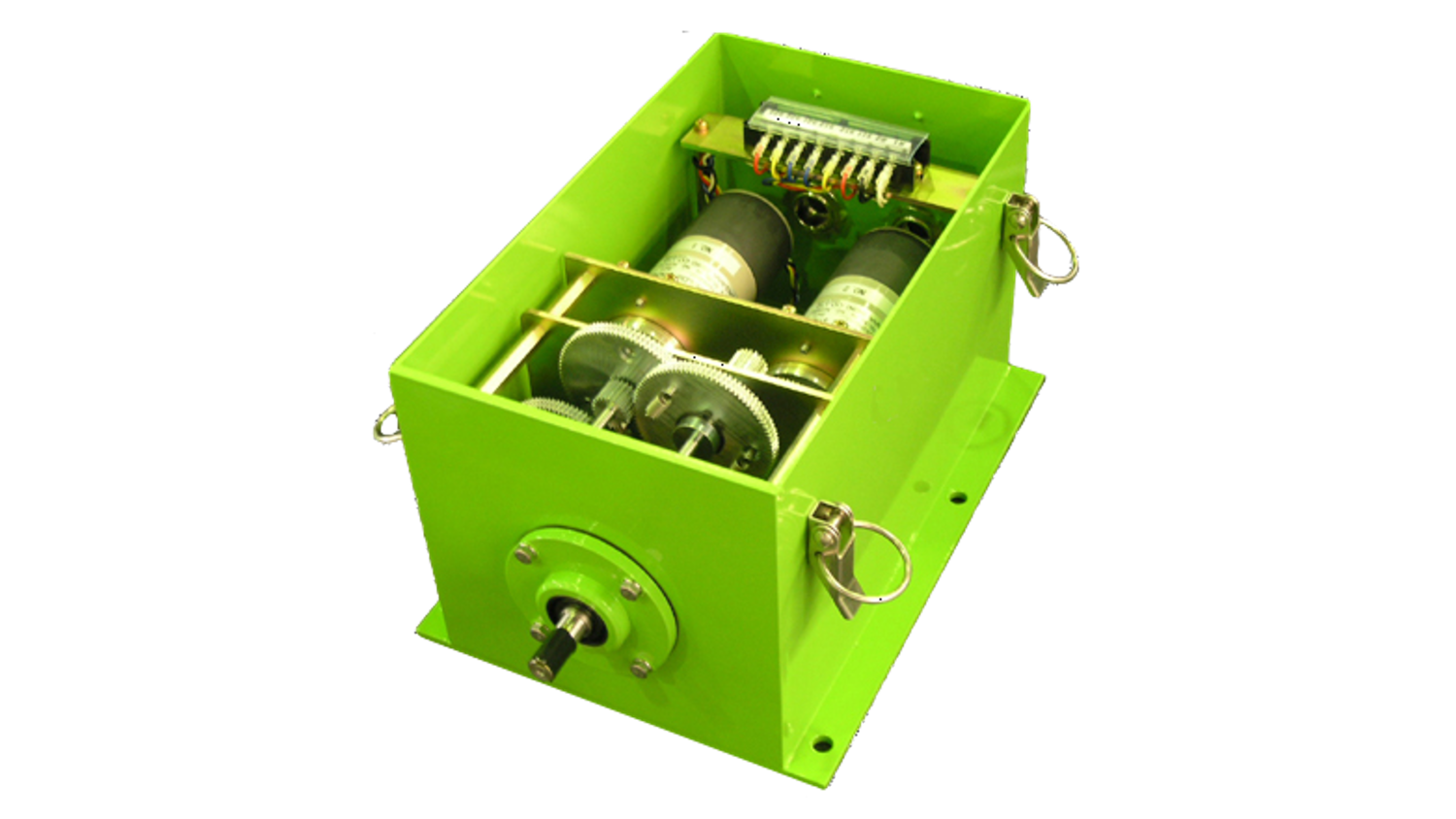

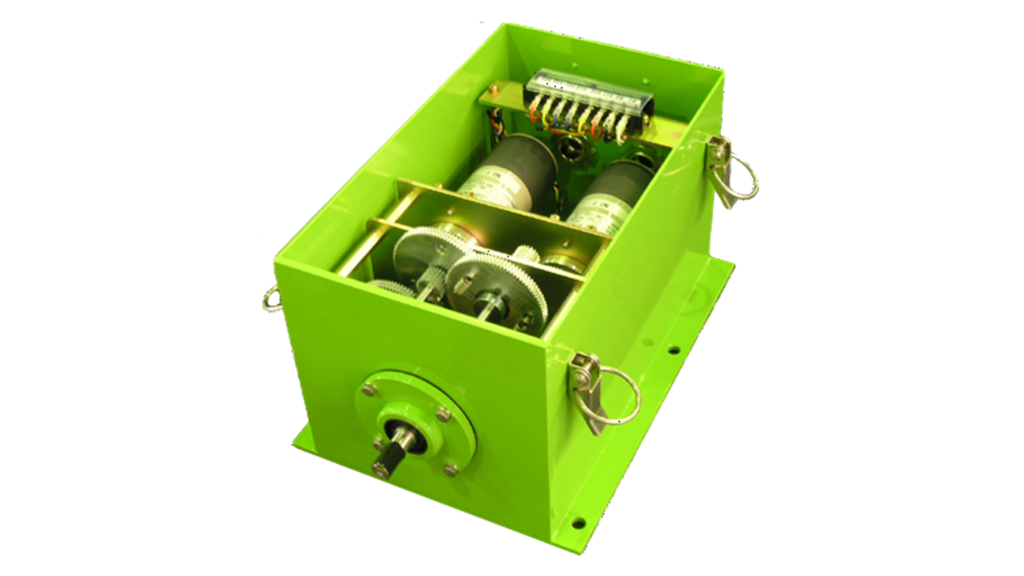

Position Detector

Position Transmitter has a built-in transmitter, and when attached to transport machine, it will notify of turning and stroke position information in real time.

For example, it is used for turning chutes of blast furnaces (steel mills) and position transmission of self-propelled trippers.

In addition to transmitters that we have prepared, it is also possible to install transmitters that are specified by manufacturer and model that customer desires.

Advantages

Since it is possible to know exact position of transport machines and mobile devices, linking with control side will lead to efficient operation.

\ Download or Request for quote /

Features of the Position Transmitter

It will be custom-made according to the customer's request.

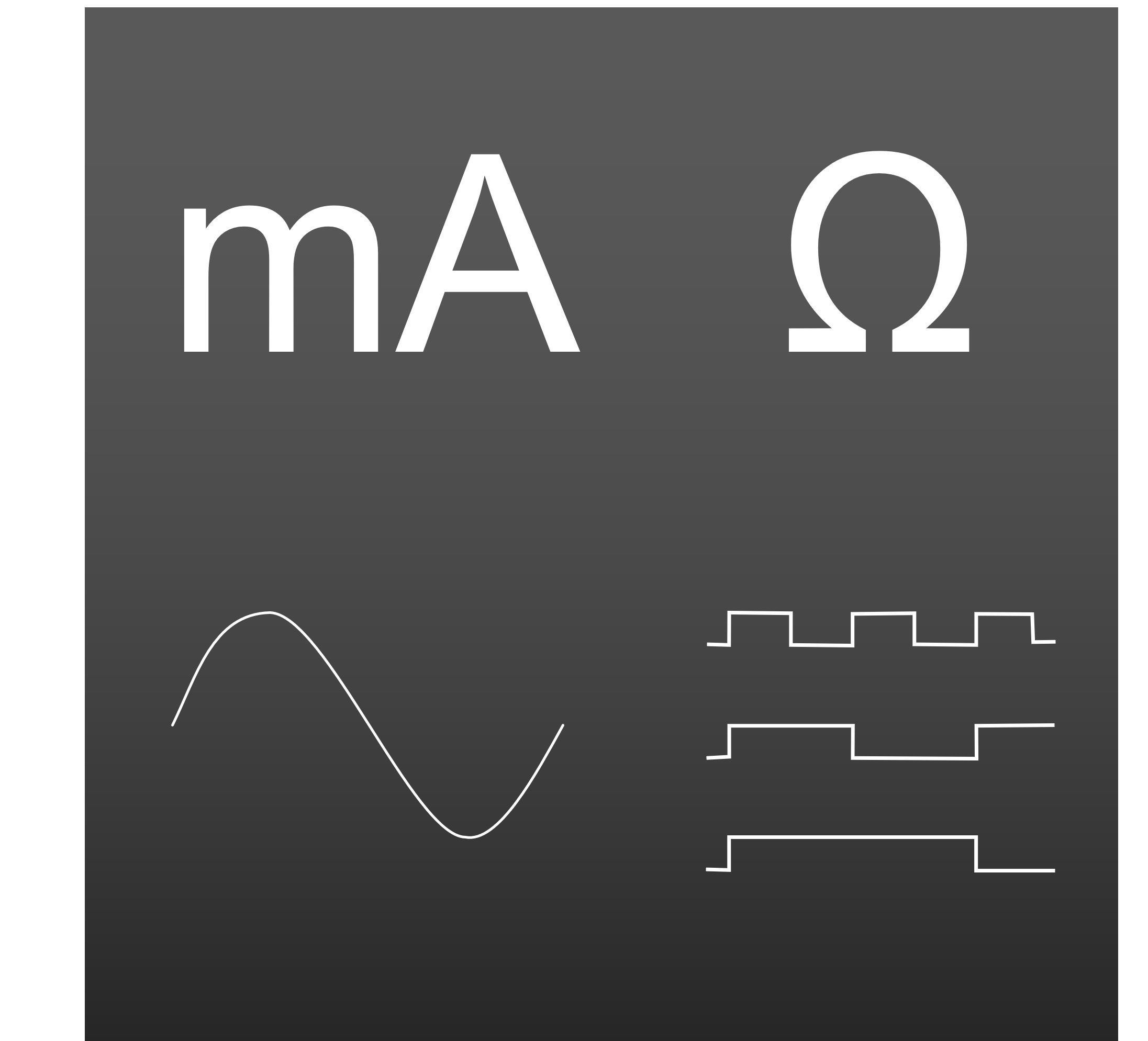

Selectable transmitter

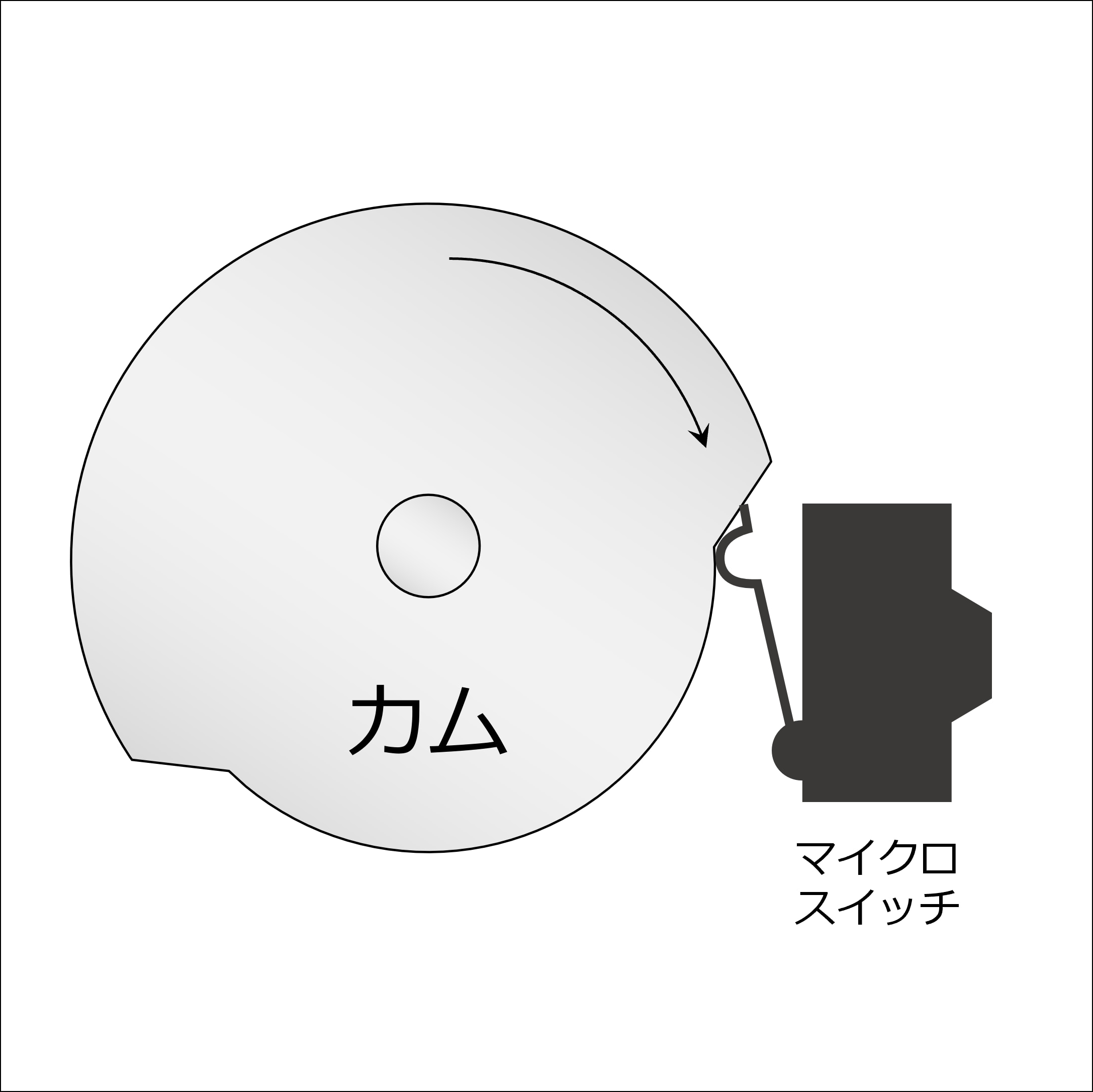

Cam switch can

also be added

Adjust output signal to desired resolution with reduction (speed increase) gear. Cam switch can also be added.

Plenty of options and

customization

Operating principle

It mainly consists of an input shaft, reducer, and transmitter. When shaft takes in rotation speed from equipment, rotation speed is transmitted to transmitter through the reducer. The transmitter outputs a signal proportional to the number of revolutions and conveys position information.

How to use?

1.Determine

mounting

position

Vibration from motors and reducers does not pose problem, but do not install near sources of large vibration such as vibrating screens or vibrating feeders.

2. Mounting

Install device (input shaft) horizontally. When attaching a sprocket or coupling to the input shaft of a device, forcible driving will cause a strong impact on bearings and gears and cause failure. When connecting the input shafts with gears or chains, do not apply a strong load to the equipment input shaft.

3. Wiring

Please wire checking connection diagram.

After wiring, securely tighten waterproof connector.

4. Adjustment

It is basically adjusted at time of shipment from the factory. When making fine adjustments, please follow instructions in instruction manual.

Maintenance

Please conduct periodic inspections.

- If a large amount of dust accumulates around Position Transmitter, clean it.

- Check whether there are no loose bolts or screws in installation section or shaft connection section.

- Apply general grease to internal gears about once every three months.

- Also lubricate oil seal of input shaft.

\ Download or Request for quote /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.