Belt Conveyor Protection Equipment

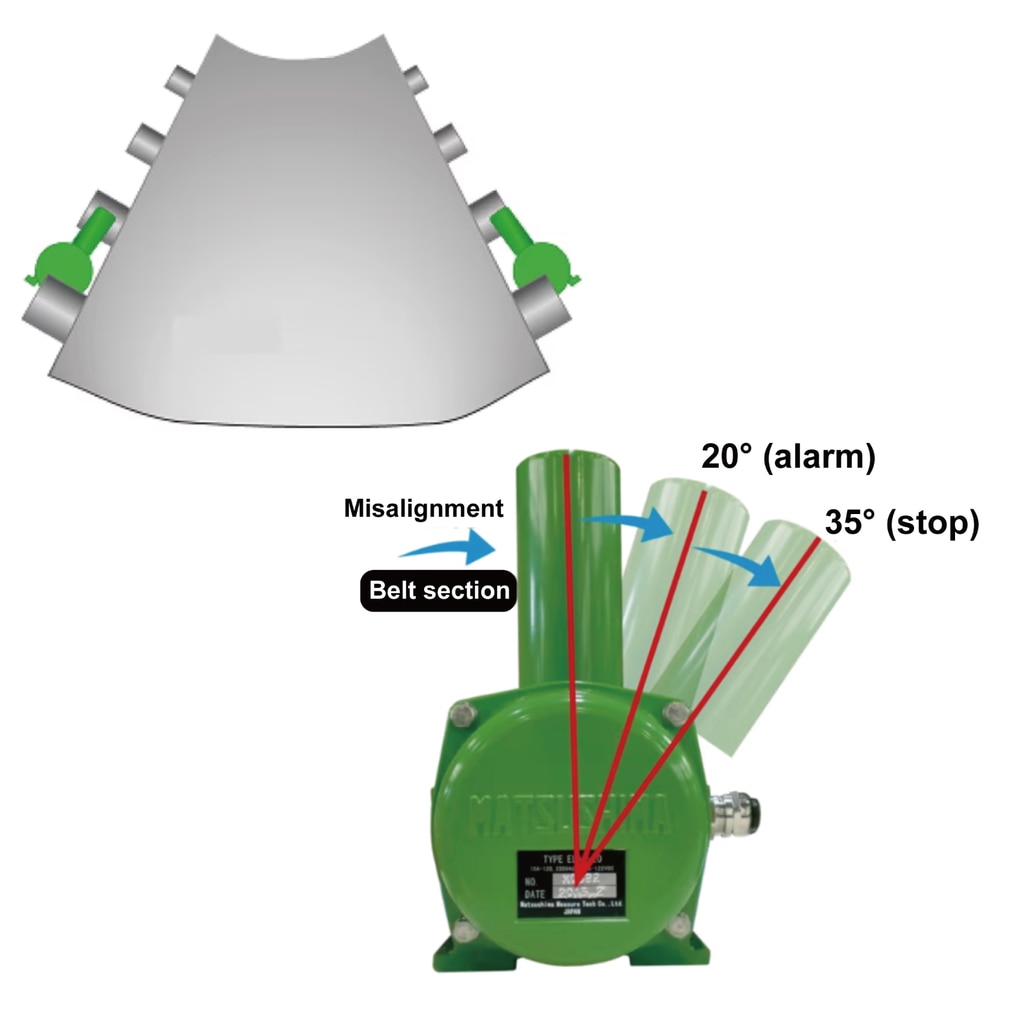

Belt Sway Switch, also called a belt misalignment detector, detects belt misalignment and swaying and notifies you.

Advantages

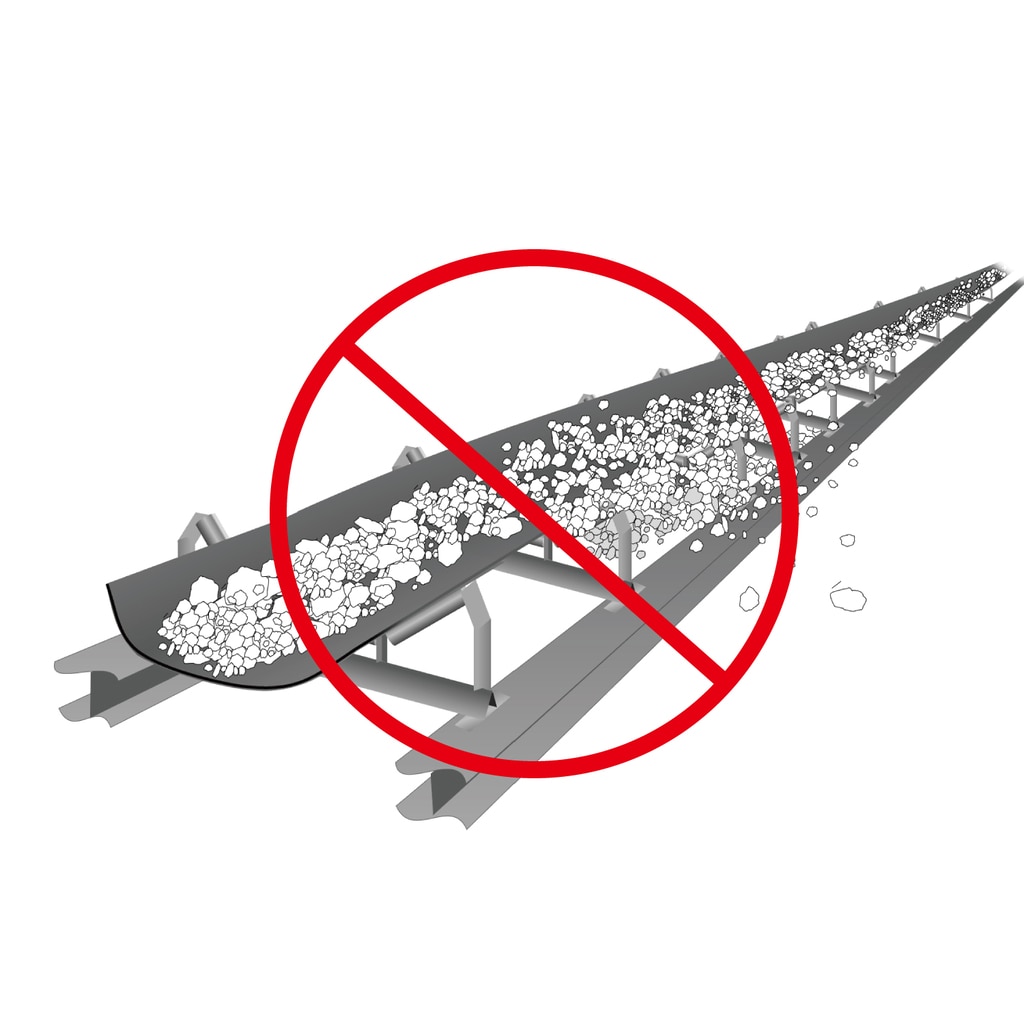

- It is possible to avoid or minimize cargo spillage due to misalignment and sway of loading.

- Since there is no spillage, the burden of cleaning work is reduced.

- It can prevent belt lugs from hitting the conveyor frame and being damaged, or from causing fires due to frictional heat.

\ Download or Request for quote /

Features of Belt Sway Switch

The main features of Belt Sway Switch are as follows.

Adjustable detection

angle

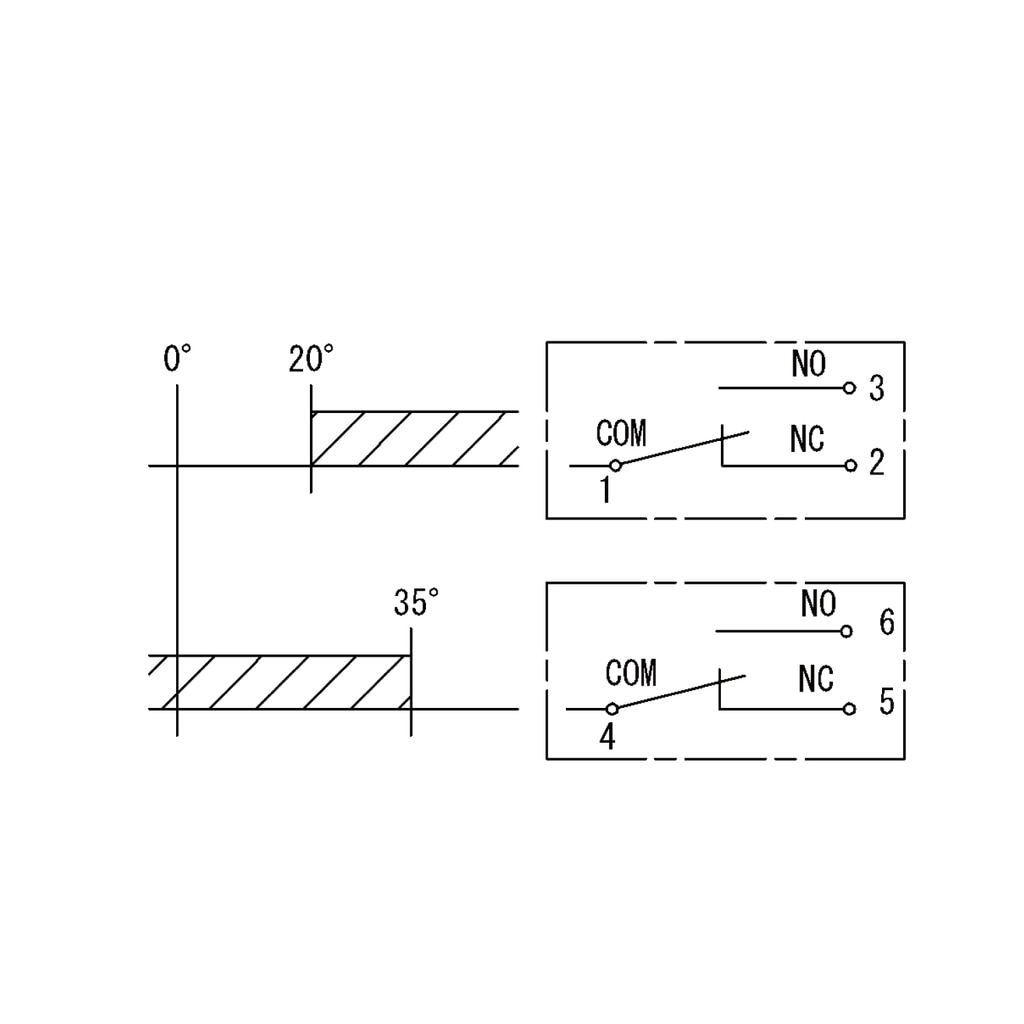

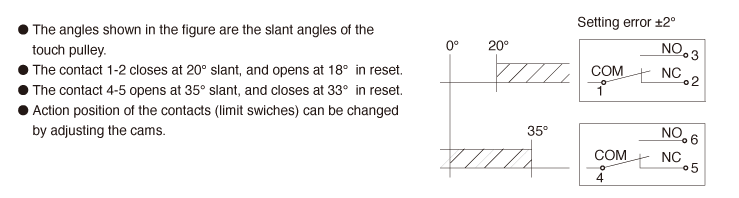

The standard detection angle is 20° for alarm and 35° for stop. However, the installation position varies depending on the site. It is possible to change the detection angle of the pulley according to the site.

Abundant lineup

"Weather proof type", "Dust Ignition -proof type", and "Flame proof type" can be selected depending on the usage environment.

Only worn pulleys

can be replaced

Pulleys are consumables because they come into contact with the belt and wear out. Reasonably priced because only the pulley can be replaced without changing the main body.

*For details, see the catalog and instruction manual.

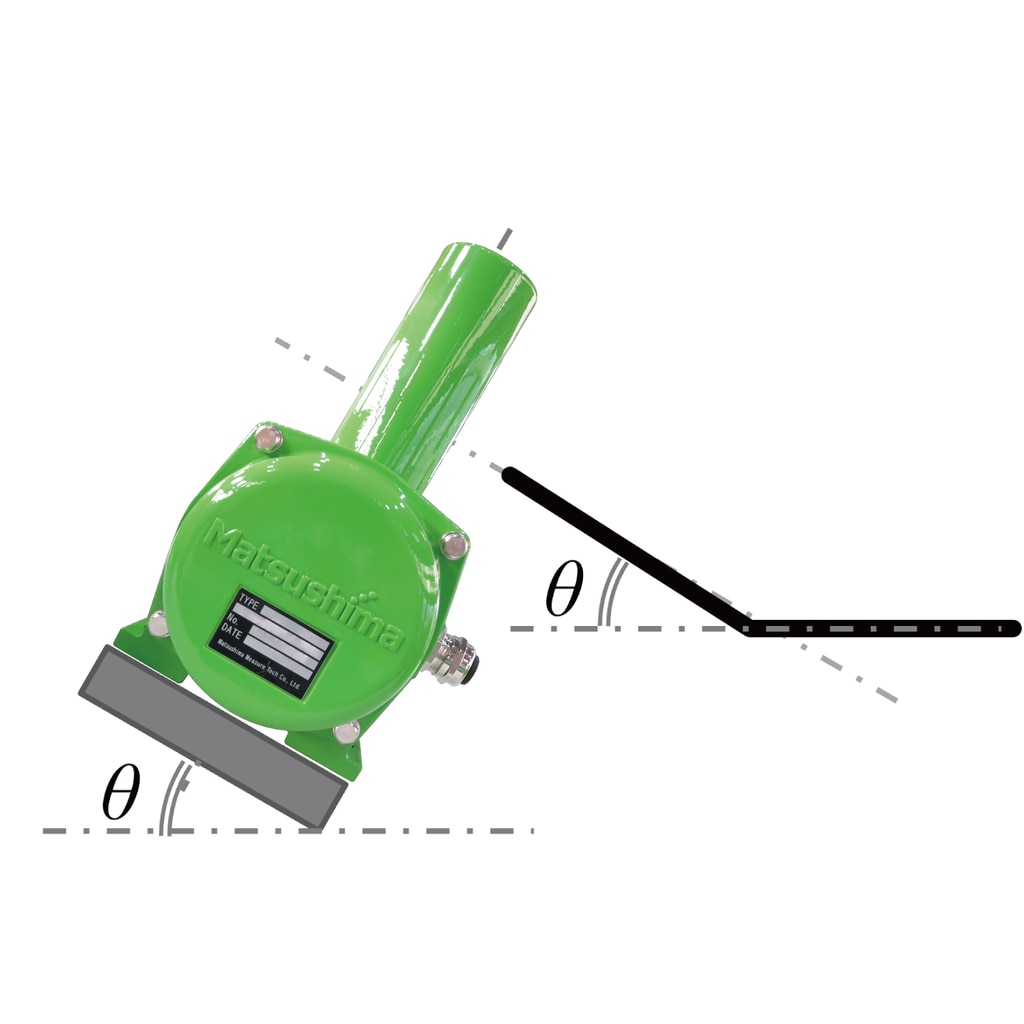

Operating principle

When the belt pushes the pulleys due to misalignment or slanting and tilts, a contact signal is sent to detect the misalignment or slanting of the conveyor.

How to use?

1.Determine

mounting position

Install in place where misalignment occurs. Decide on installation location that avoids falling ore from the conveyor or a location subject to large vibrations or shocks.

2. Mounting

Provide a mounting base for Belt Sway Switch. Install Belt Sway Switch so that it is perpendicular to the belt. It is recommended to install cover in case of falling mines.

3. Wiring

The contact signal is a dry contact. Avoid direct input to motors and sequencers, and use magnet conductors or relays.

4. Adjustment

No adjustment is required as it has been adjusted at the factory. However, it is possible to adjust the detection angle in the field if necessary.

*For details, please refer to the instruction manual.

\ Download or Request for quote /

Maintenance

Periodic inspection is recommended as it is a safety switch.

- If there is a lot of dust on the pulley, it may cause malfunction, so clean it.

- If the portion of the touch pulley that comes into contact with the belt is severely worn, replace it.

- Confirm that the microswitch operates when the touch pulley is tilted.

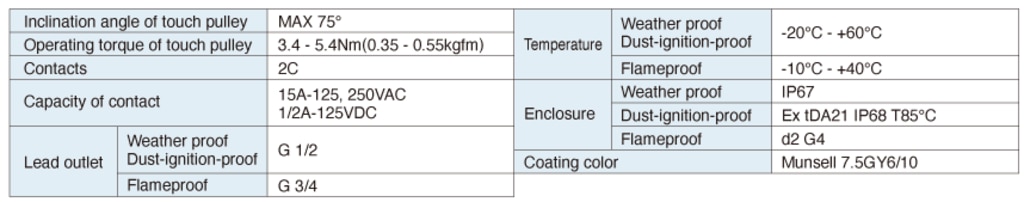

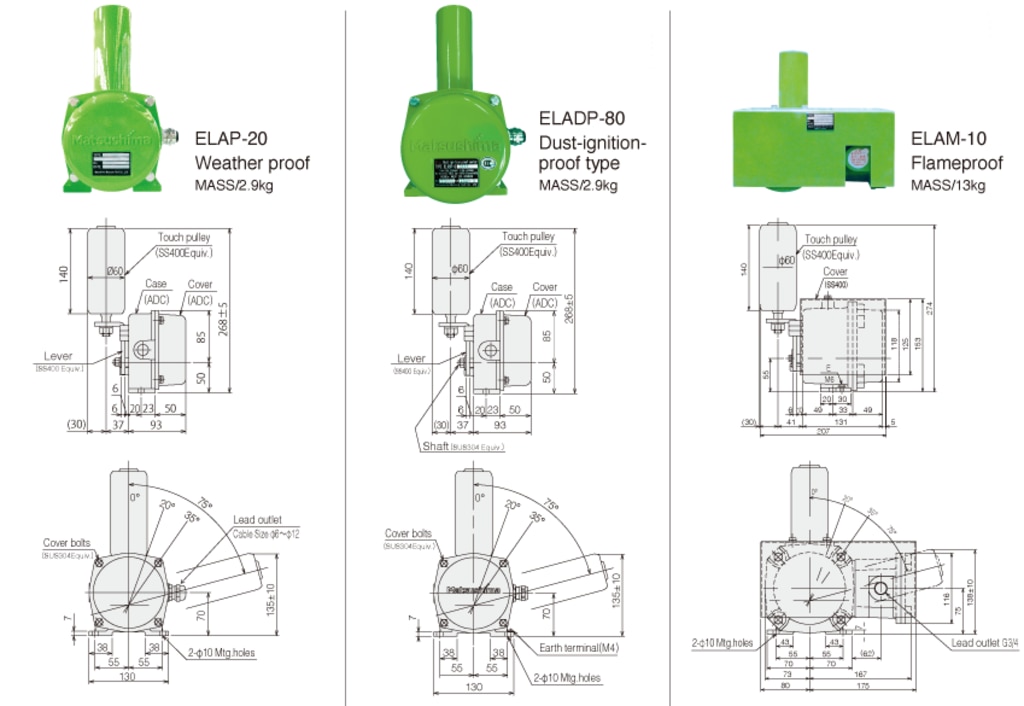

Model Lineup

Specifications

Dimensions(mm)

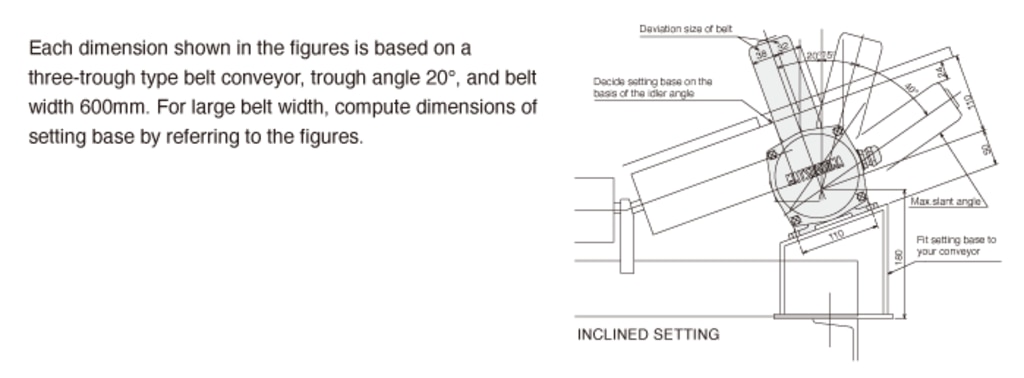

Mounting

Operation description

\ Download or Request for quote /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.