Belt Conveyor Protection Equipment

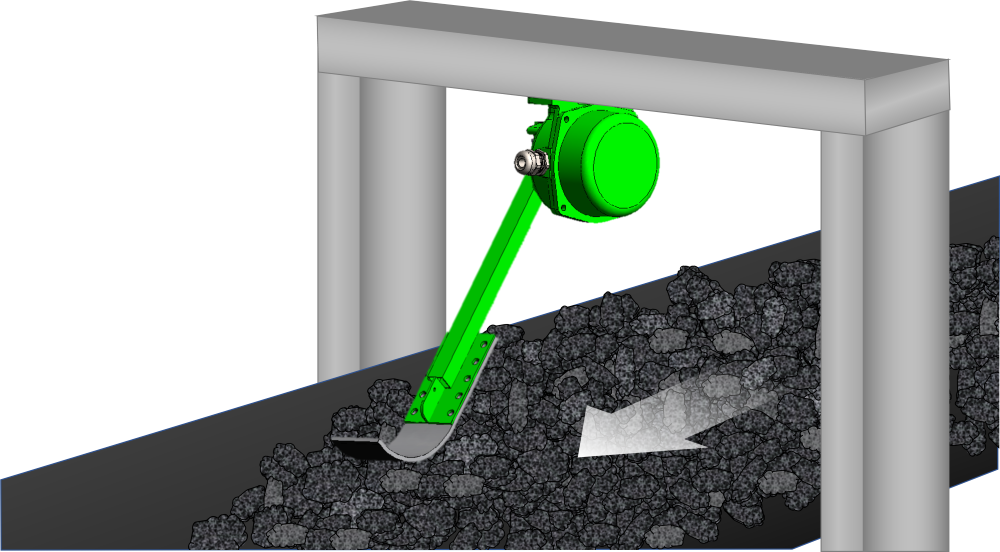

Flow Detecor detects and notifies you if the cargo on belt conveyor is running out. It helps to avoid troubles in post-process.

Advantages

- Out-of-load can be detected in advance to avoid quality defects in subsequent processes.

- It can also be used to predict clogging and overflow of conveyor transfer chutes.

- When transporting multiple raw materials on a single conveyor, mixing of raw materials can be avoided because the next raw material can be added after confirming that the load is completely exhausted.

- Detecting that a load has arrived at a certain position on the conveyor and activating the conveyor in the post-process will lead to energy saving.

\ Download or Request for quote /

Features of Flow Detector

Detection blades with wear-resistant

treatment

The detection blades are subject to wear because they are constantly in contact with the material and the belt. We have applied wear-resistant treatment to the detection blades to increase their durability.

Curved detection blade

By giving a curve to the detection blades, sudden fluctuations in unevenness of cargo are mitigated.

Operating principle

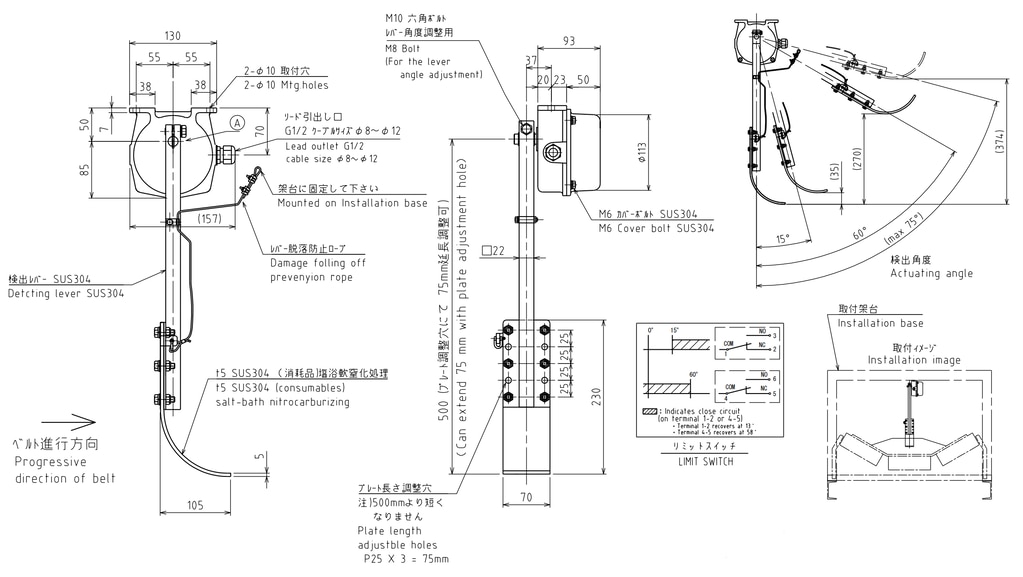

Install the detection vane as shown in the figure in the direction of the load flow.

The detection lever tilts when there is a load on the belt conveyor. Depending on the tilt angle, the contact will be output to inform you.

It supports 2 contact outputs, and the detection angle and contact output are as follows.

・Contact output 1: ON at 15° or more (for NC connection)

・Contact output 2: OFF at 60° or more (in the case of NC connection),

the detection angle becomes 0° when there is no load.

Maintenance

Periodically check degree of wear of detection blades and looseness of lever.

If it is badly worn, replace it.

Model lineup

| TYPE | EFSL-155S |

| ENCLOSURE | IP67 |

| ALLOWABLE TEMP. | -10~+50℃ |

| ACTUALLING ANGLE | 15°、60° |

| OPERATIONAL ABILITY OF LEVER | 10N±20% / operating angle 60° |

| OUTPUT CONTACT | 2C |

| CONTACT CAPACITY | AC250V 15A |

| SWTCH | AC micro switch |

| COATING COLOR | MUNSELL7.5GY6/10 |

| MASS | 3kg |

\ Download or Request for quote /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.