Belt Conveyor Protection Equipment

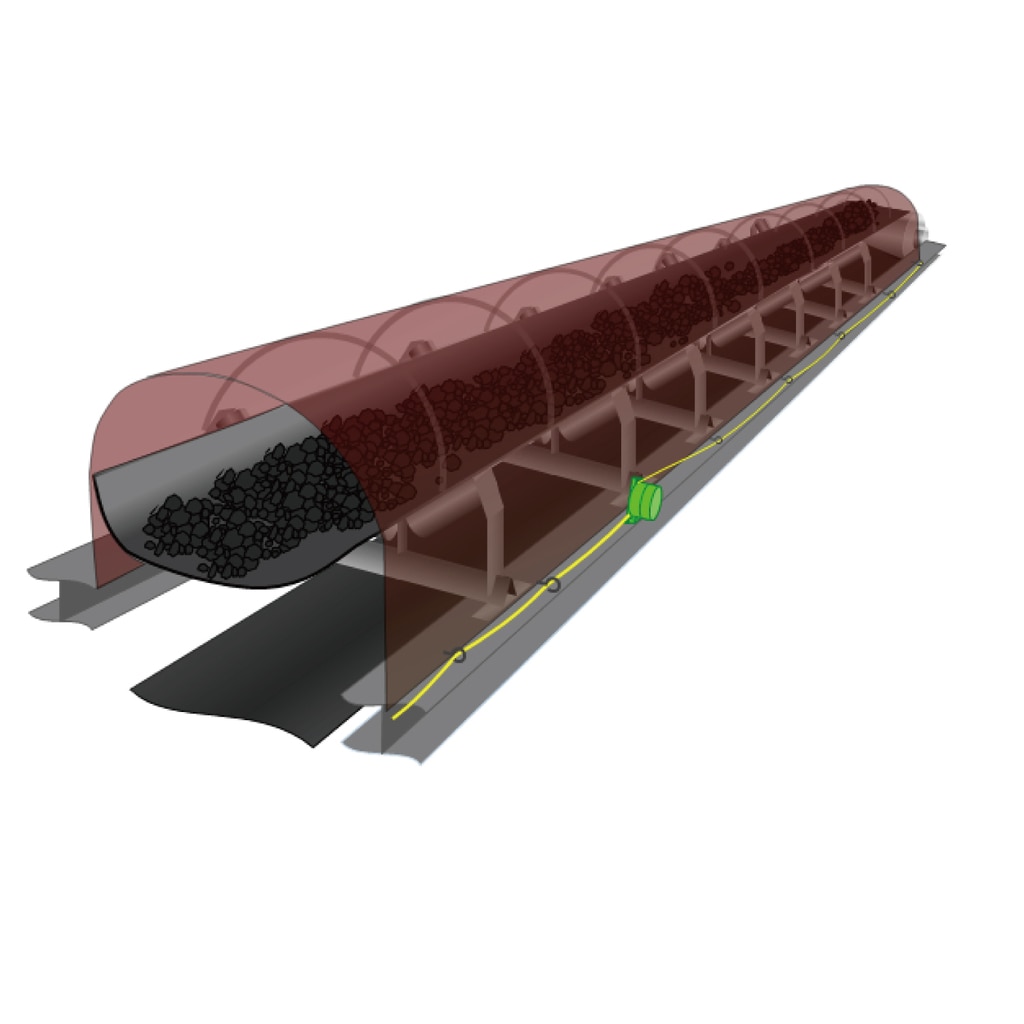

PULLSTOP is a switch for emergency stop when an accident occurs around belt conveyors and transport machines, similar to Pull Cord Switch. Mainly used for belt conveyors that transport raw materials (ore, coal, lime, gravel, etc.) at production sites. Furthermore, safety is ensured with four functions that consider risk assessment.

Advantages

- It can be used as an emergency stop device required by occupational safety and health regulations to prevent accidents resulting in injury or death to workers.

- By pulling the wire rope from anywhere on the conveyor, the facility can be stopped immediately, minimizing damage.

- It is also effective for safety measures before work. Activating the pull stop while working around the conveyor prevents the conveyor from being started by mistake. Serious accidents can be avoided.

\ Download or Request for quote /

Features of PULLSTOP

The main features of the PULLSTOP are:

Risk assessment design

In addition to the basic function of PULLSTOP, four functions have been added in consideration of risks to increase safety.

- Rope cut detection

- With emergency stop push button

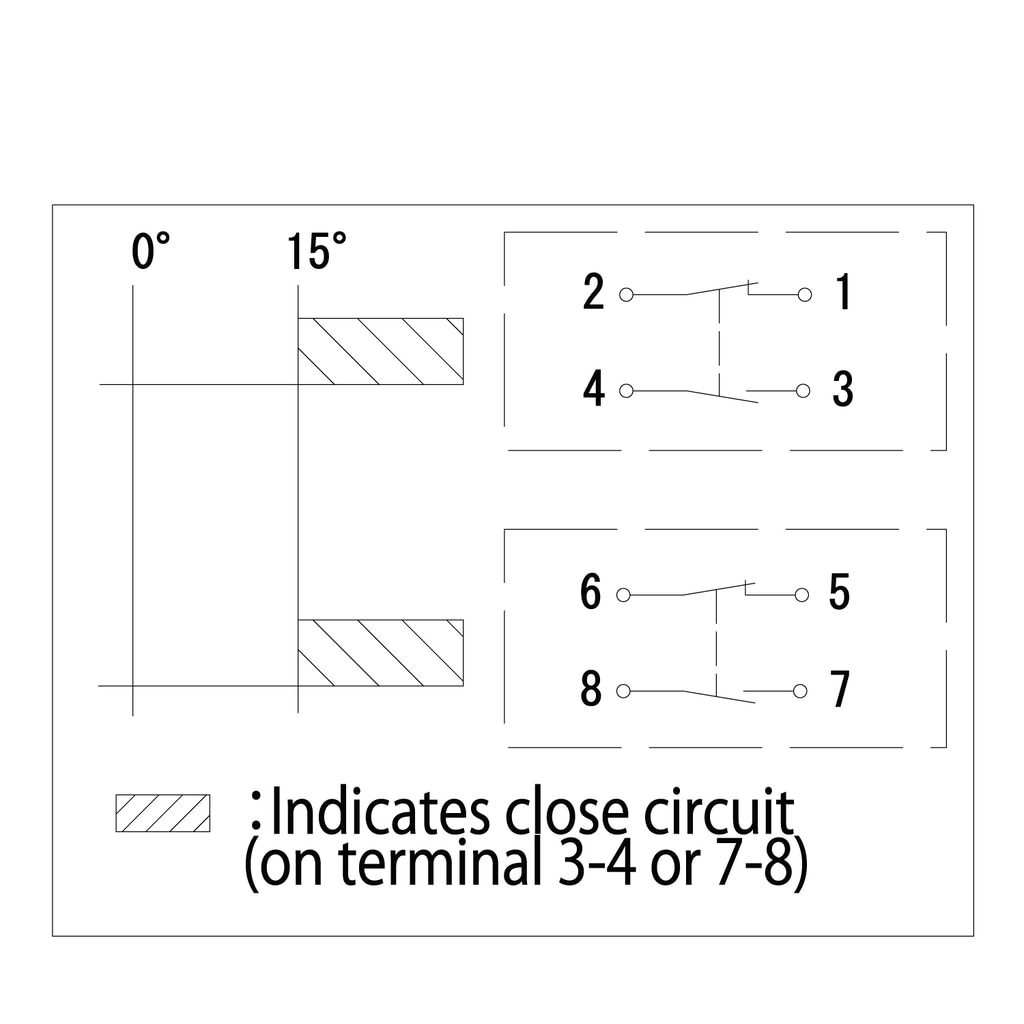

- It can be stopped even if either of double limit switches

fails.

- Forced Separation Mechanism

When the switch is welded, the weld is forcibly peeled off by a mechanical mechanism.

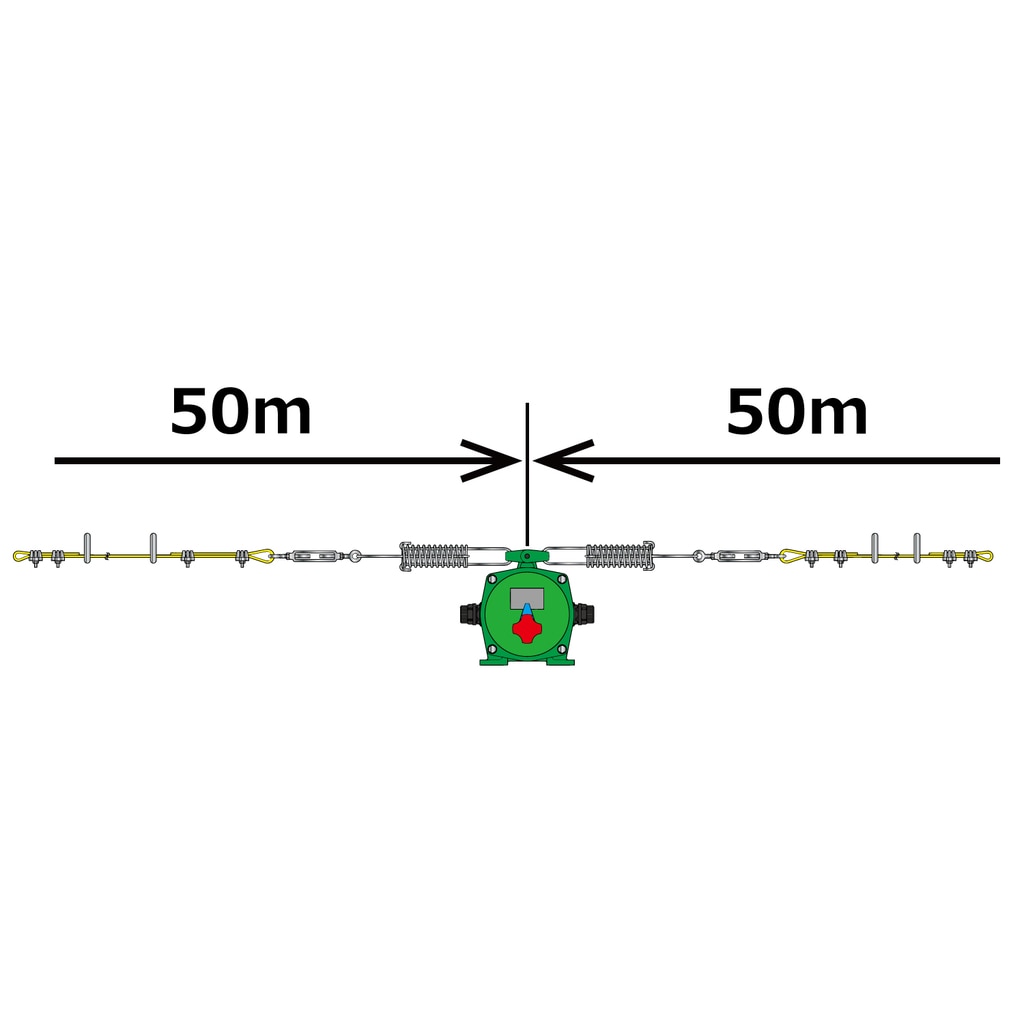

1 unit covers 100m

One unit can cover about 100m. You can reduce work load during installation and in event of an emergency.

Safety design

Some emergency stop switches that use wire rope may malfunction due to the wire rope expanding and contracting due to the difference in temperature between summer and winter.

PULLSTOP has structure that pulls the wire rope from both sides of main body, which cancels out expansion and contraction and prevents malfunction.

*For details, see the catalog and instruction manual.

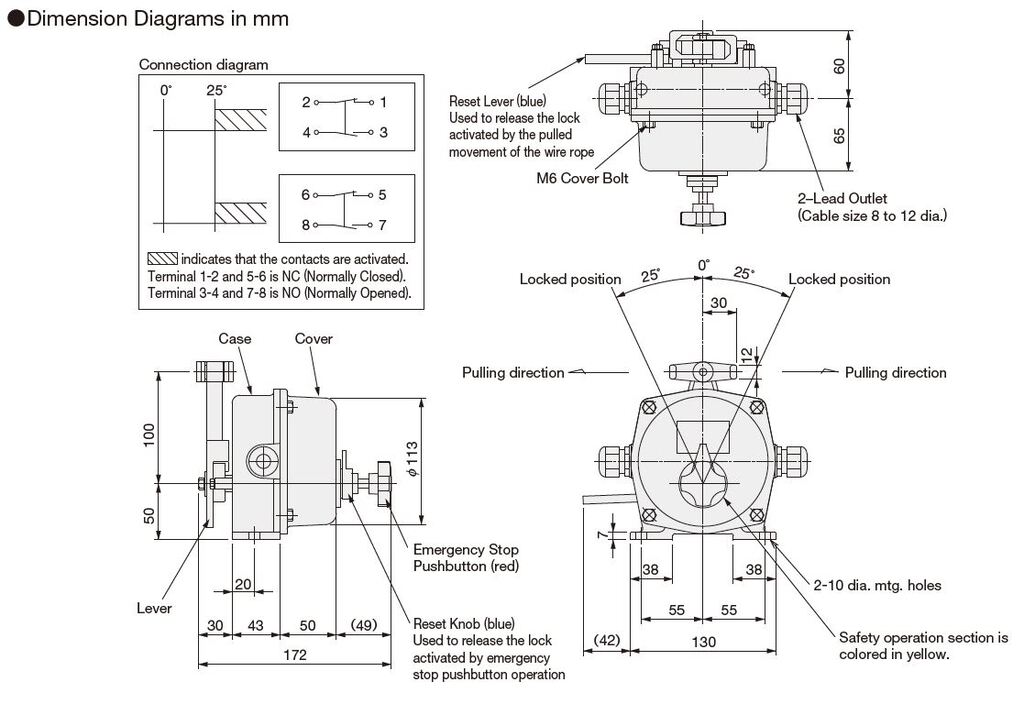

Operating principle

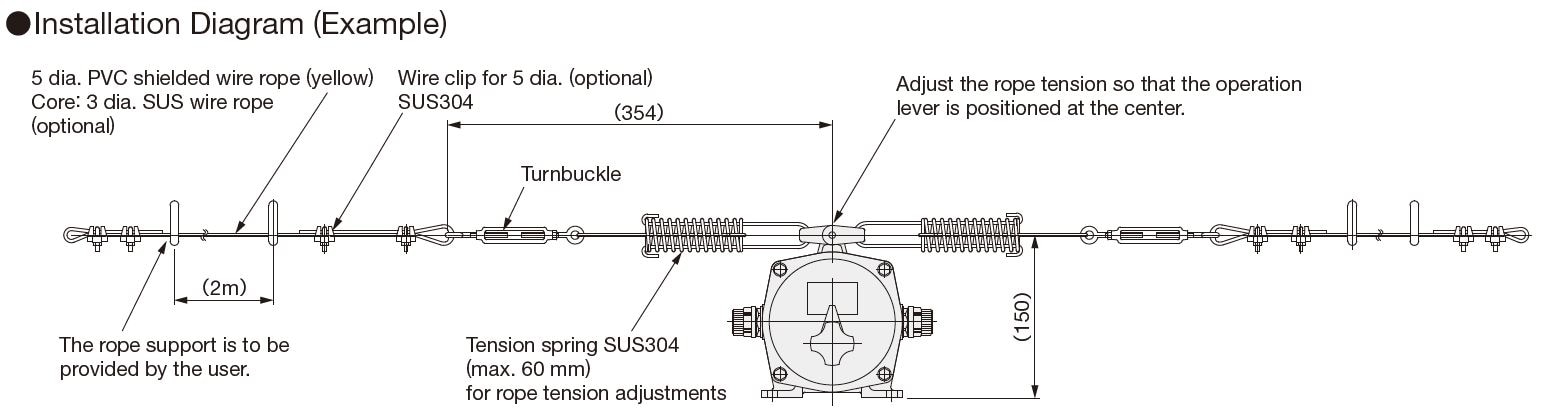

If you connect wire ropes to both sides of PULLSTOP lever and attach wire ropes along belt conveyor, you can pull the wire rope from anywhere on the belt conveyor to activate the PULLSTOP and stop the equipment in an emergency. .

※The video is explained using Pull Cord Switch of sister product.

How to use?

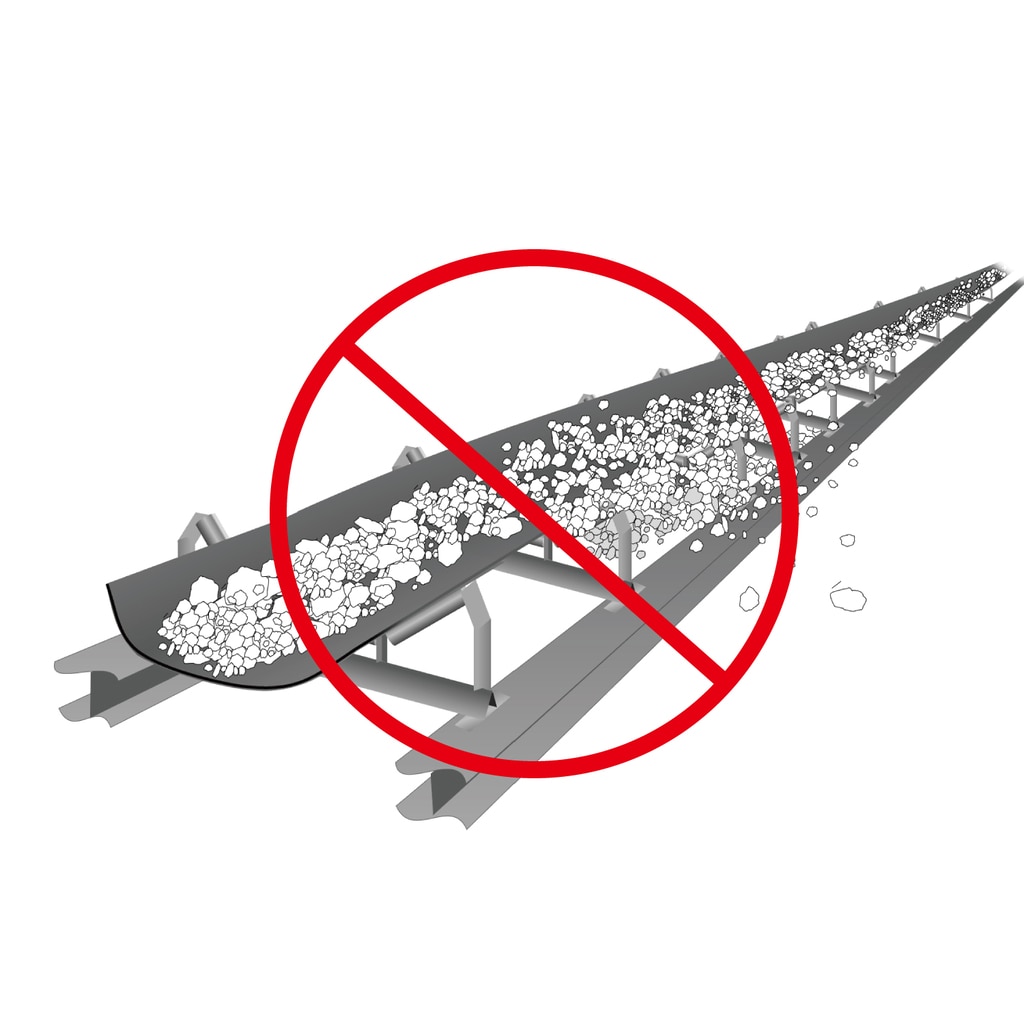

1.Determine

mounting position

Decide on an installation location that avoids falling ore from conveyor or location subject to large vibrations or shocks.

2. Mounting

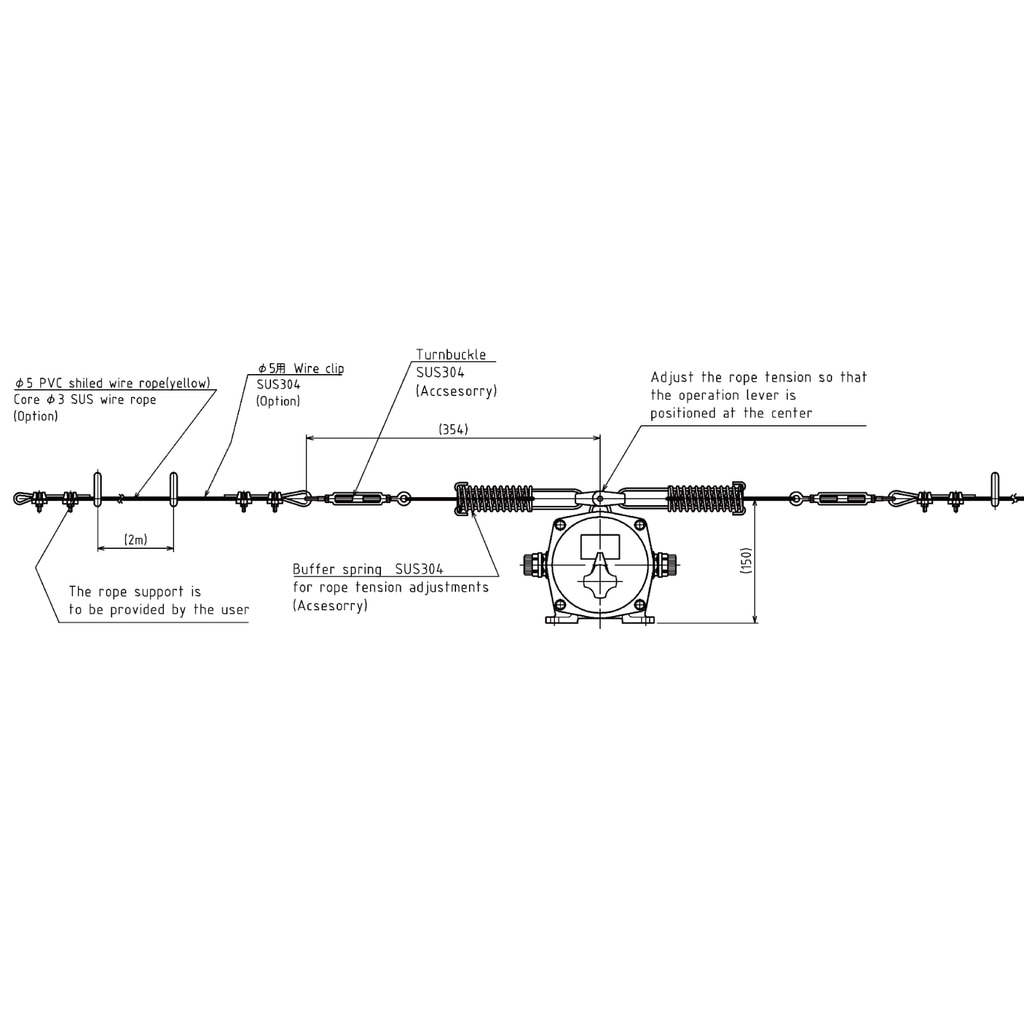

Provide installation base for the PULLSTOP. It is recommended to install a cover in case of falling mines. The length of the wire rope for operation is up to 50m on one side.

3. Wiring

The contact signal is a dry contact. Avoid direct input to motors and sequencers. In addition, "Control Category 4" can be ensured by using safety relay units instead of magnet conductors and relays.

4. Adjustment

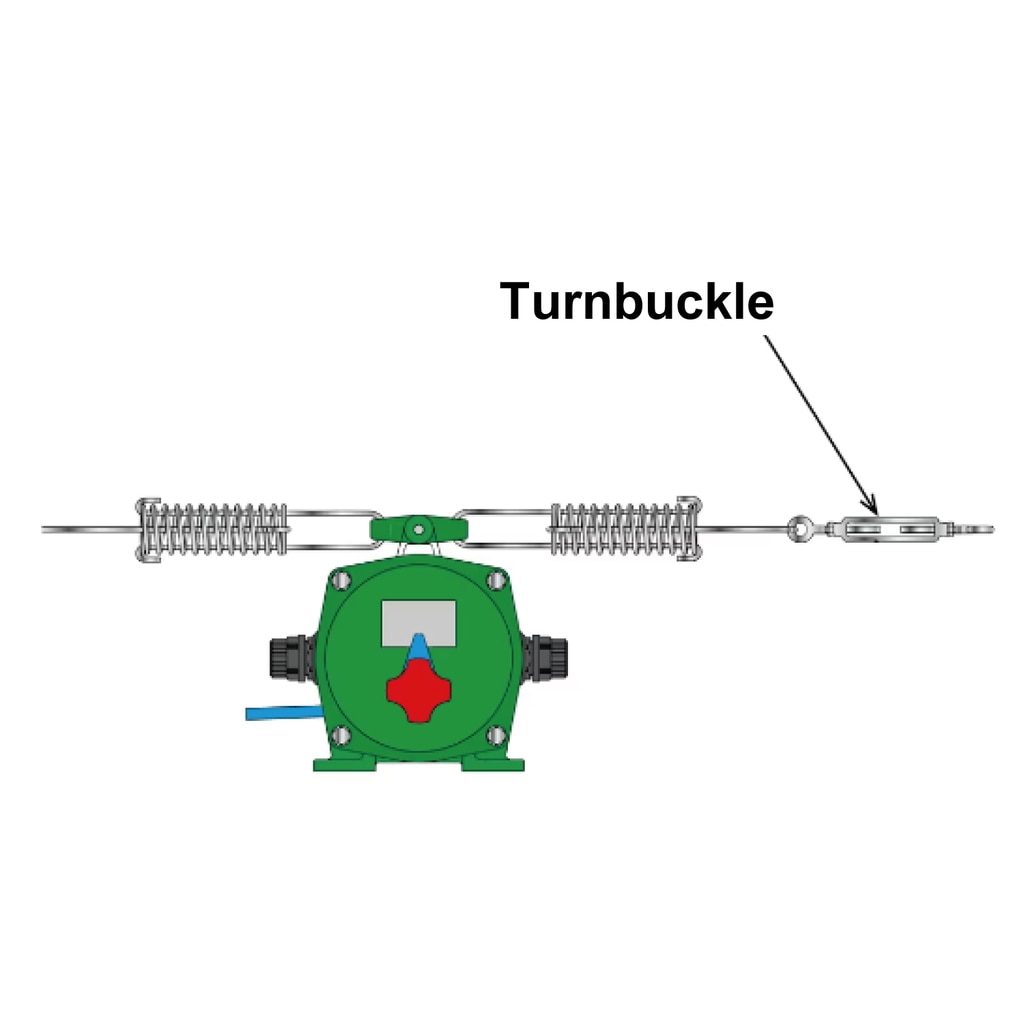

After the ropes are stretched on both sides, fine-tune the operation levers with the included turnbuckles so that they are in the neutral position.

*For details, please refer to the instruction manual.

\ Download or Request for quote /

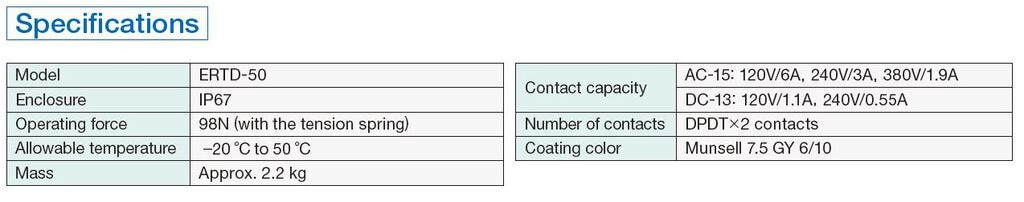

Model lineup

- Turnbuckles and tension springs are accessories.

- Wire ropes and wire clips are optional.

- Please prepare the rope support by yourself.

\ Download or Request for quotes /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.