Belt Conveyor Protection Equipment

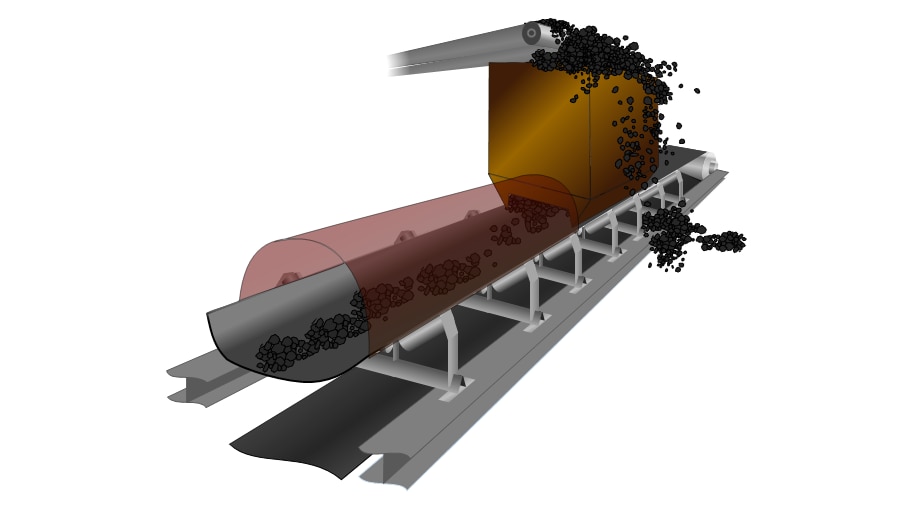

Chute Switch is sensor that detects chute clogging that occurs when belt conveyors are transferred. This helps prevent overflows, production losses, and air pollution. It is widely used in ore transport conveyor chutes at coal-fired power plants and steel mills.

Advantages

Early detection of chute clogging

- You can avoid overflow and suppress dust generation to the surrounding environment.

- Conveyor damage and fire can be avoided.

- It is possible to avoid quality defects due to the supply to the next process being interrupted.

\ Download or Request for quote /

Features of Chute Switch

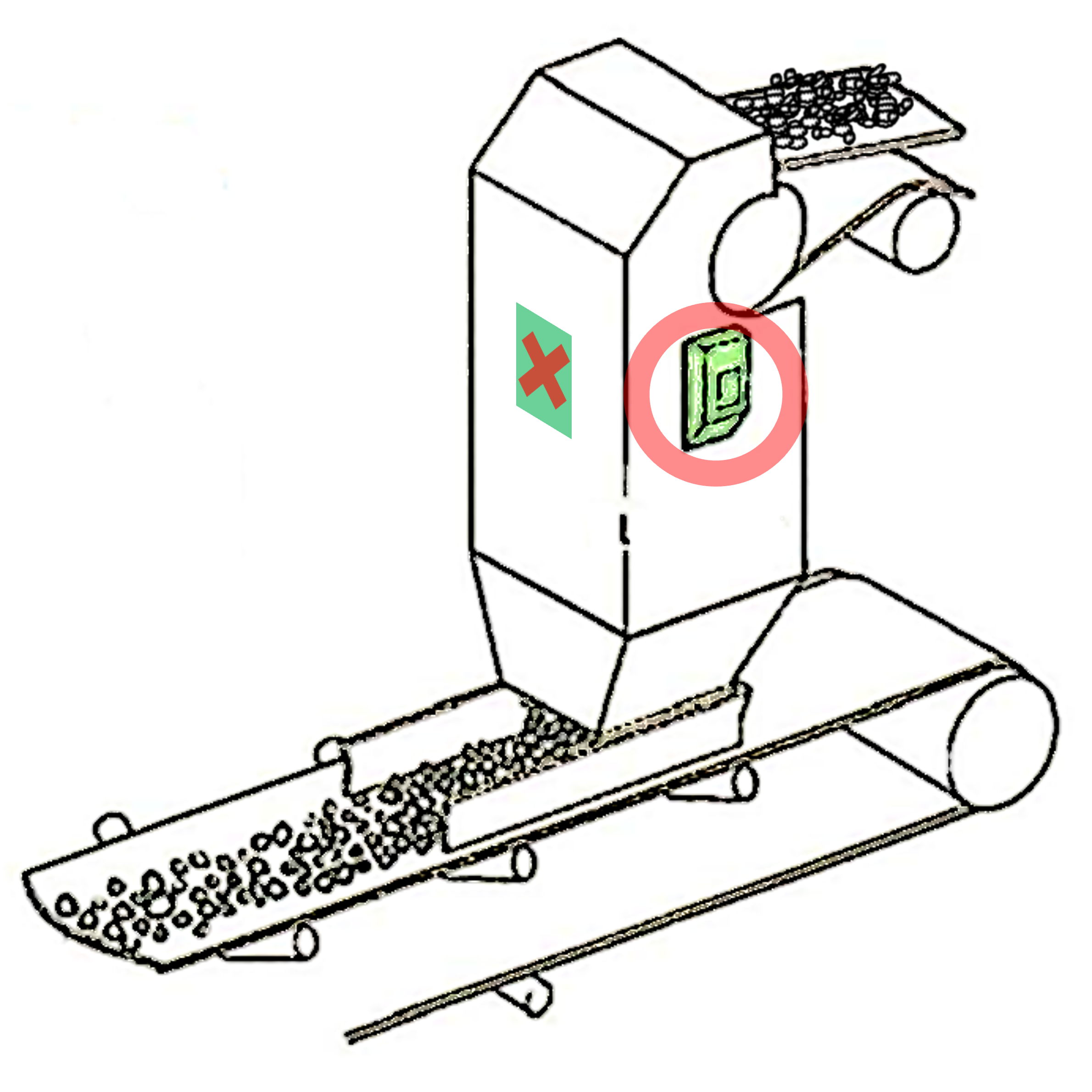

Do not protrude

into chute

Since there is no protrusion in chute, it does not interfere with transportation.

No power supply

required

Power supply is not required because mechanical movement of limit switch can be detected.

Explosion proof

Intrinsically safe Exia Ⅱc

Please use it in combination with a relay barrier.

*For details, please refer to the instruction manual.

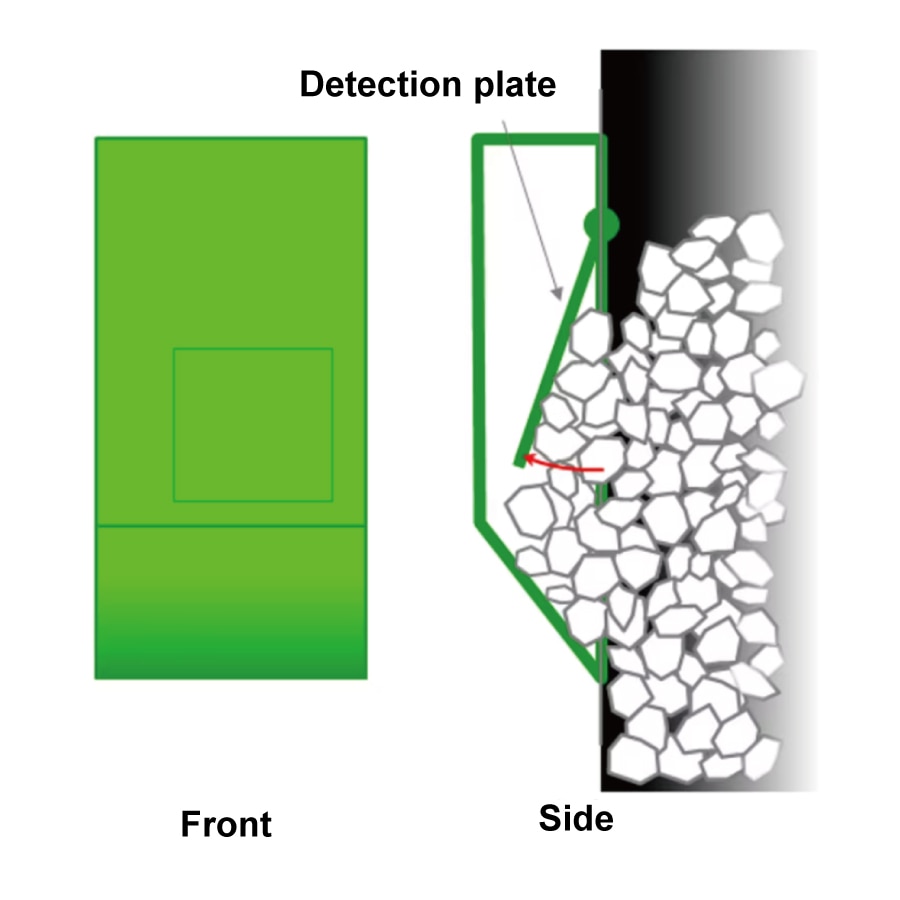

Operating principle

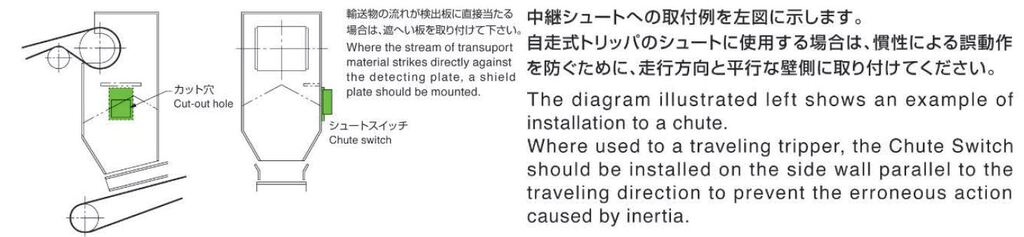

Install by drilling a hole in side wall of chute.

When the chute is clogged, the conveyed object pushes the detection plate inside the chute switch.

In conjunction with this, the limit switch works.

How to use?

1.Determine

mounting position

Decide upper level you want to detect. Since there is a possibility that material thrown from the conveyor may come flying, please decide the installation position to avoid it.

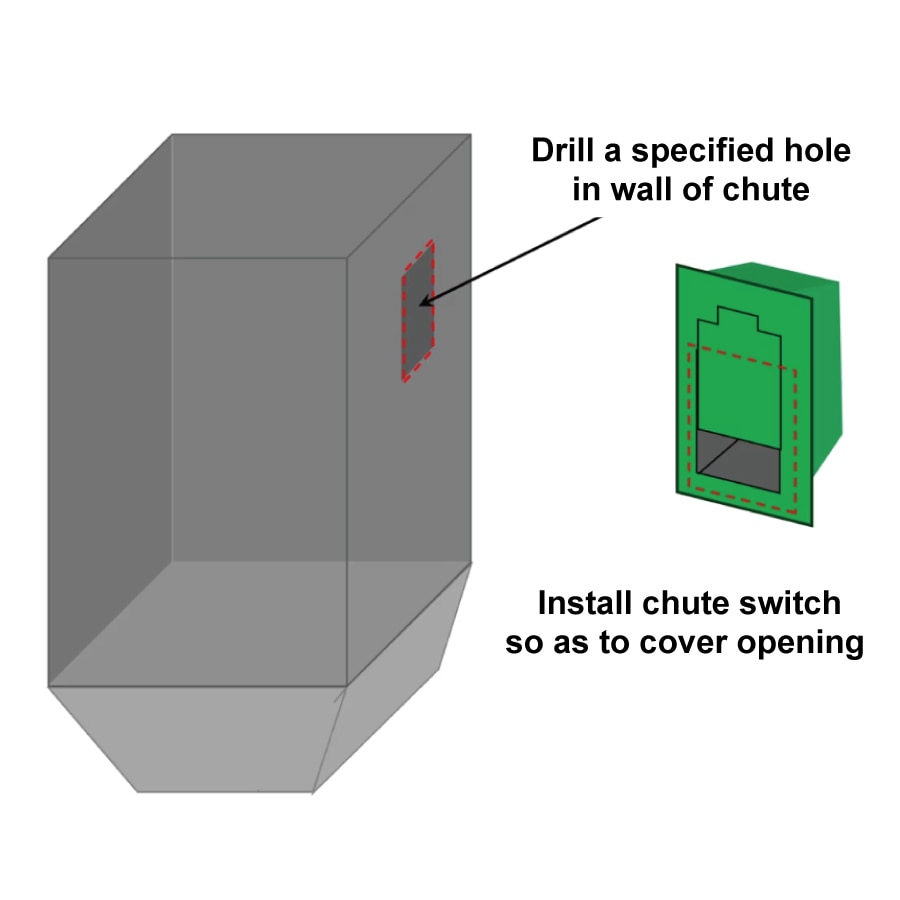

2. Mounting

Once the mounting position has been determined, drill a specified hole in location where you want to detect. Weld a chute switch over the hole.

3. Wiring

Wire to contact output.

No power supply required.

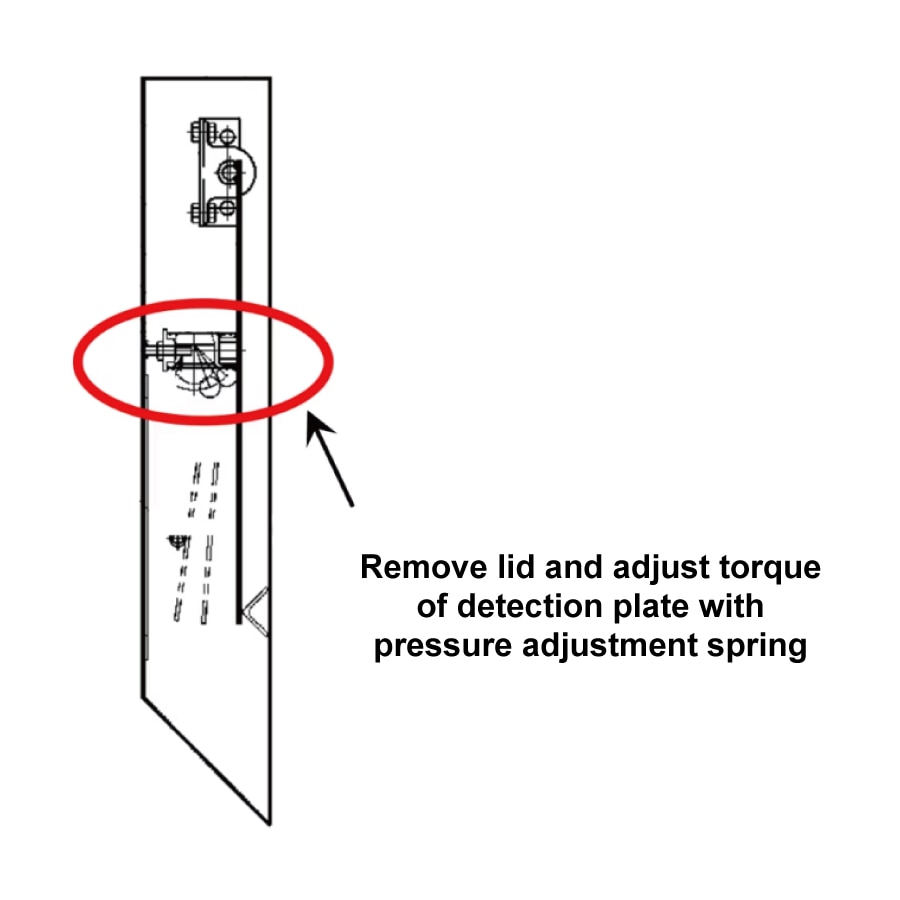

4. Adjustment

Adjust torque of detection plate with adjustment spring.

*For details, please refer to the instruction manual.

\ Download or Request for quote /

Maintenance

Check if there is dust on detection lever or limit switch. If there is adhesion or sticking, clean it.

Model lineup

Specifications

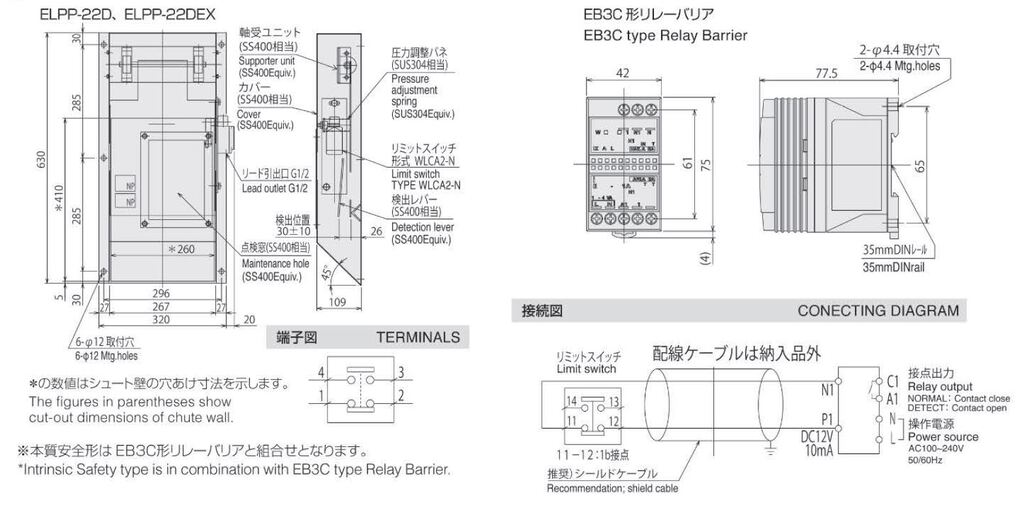

Dimensions(mm)

Mounting

\ Download or Request for quote /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.