Belt Conveyor Protection Equipment

Advantages

-

Detecting belt conveyor slippage can prevent conveyor fires and chute clogging.

-

Early detection of belt rupture minimizes chute clogging and cargo spillage.

-

Accidents can be prevented by detecting overspeed of rotating bodies such as cranes and construction elevators.

-

It is pre-adjusted before shipment, so no on-site adjustment is required.

\ Download or Request to quote /

Features of Speed Relay

No power supply required.

Since it is magnetic, it does not use a power supply.

Resistant to electrical noise

Mechanical detection is highly reliable and can be used in environments with electrical noise.

Suitable for long-term continuous operation

Easy to maintain.

Long-term continuous operation is possible without lubrication or inspection.

Abundant lineup

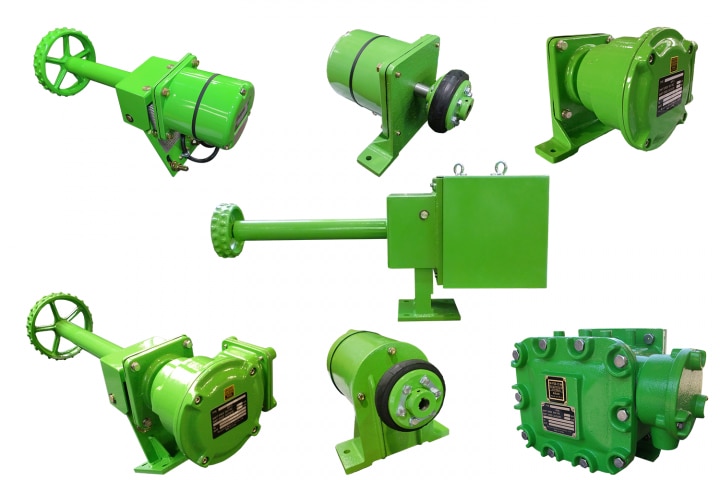

We offer a wide range of lineups to match the on-site environment.

See our model lineup for details .

*For details, see the catalog and instruction manual.

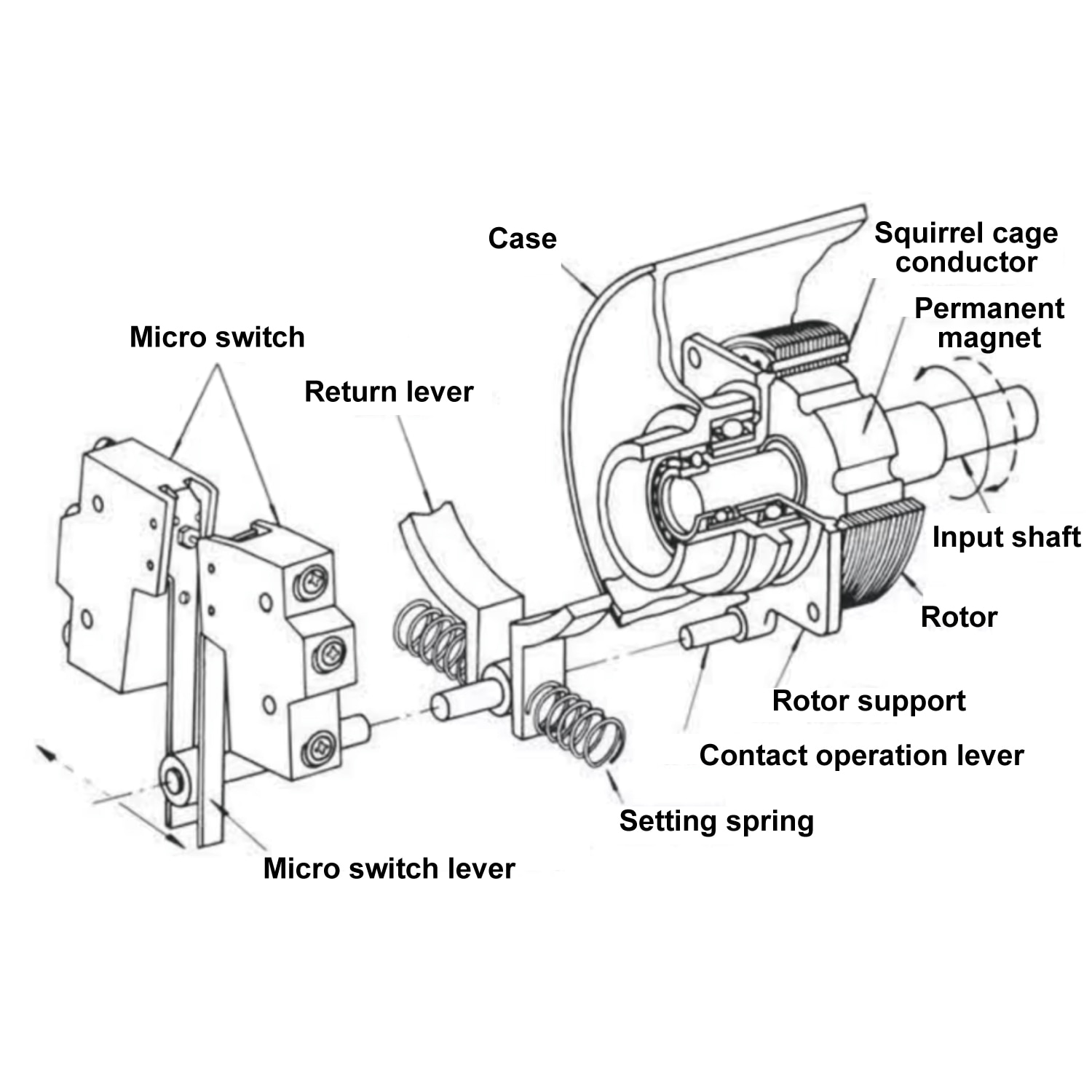

Operating principle

The main structure of a speed switch is a shaft with a permanent magnet and a rotor around it. When the rotation is transmitted from the shaft of mechanical device to the shaft of the speed switch, the permanent magnet rotates together. Rotational force is also generated in the rotor in proportion to the rotational speed of this permanent magnet. At this time, contact operating lever extending from the rotor is designed to push the microswitch. In addition, the contact operation lever is controlled by the return lever and setting spring, and when the rotation speed drops due to slip, the force of the return lever overcomes the rotational force of the rotor. Then, the contact operating lever no longer has the force to hold down the microswitch, and slip can be detected.

Overspeed detection is the opposite of this, and the spring is adjusted so that the microswitch is pressed by overspeed while it is not pressed under normal rated conditions.

How to use?

1.Determine

mounting position

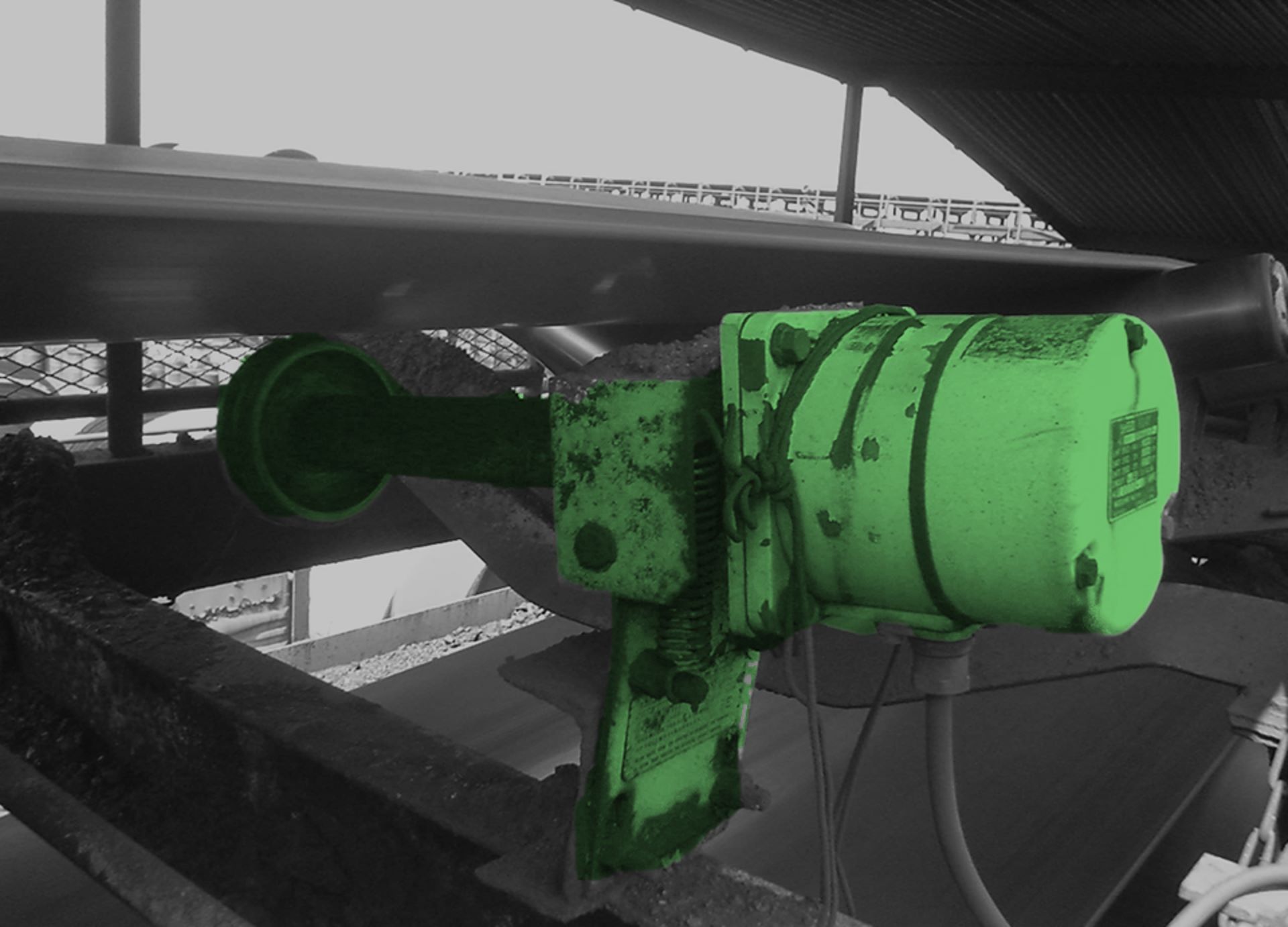

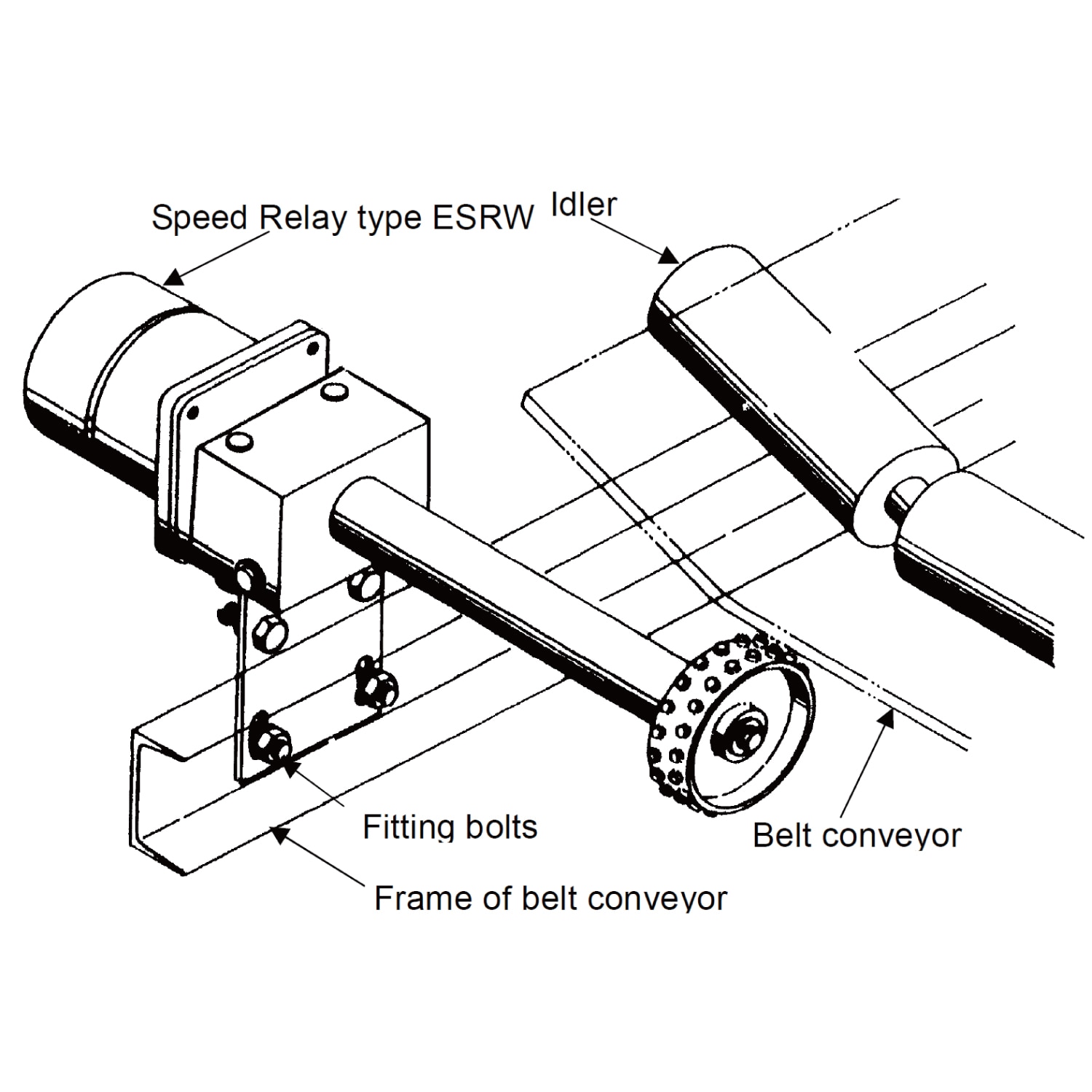

The mounting position changes depending on how the rotation is captured. There are two methods, one is to take in directly from the rotating body via a coupling, and the other is to take in by pressing the touch pulley against the belt.

2. Mounting

Please connect shaft input type to rotating body of the machine with a coupling.

Press the drive roller type so that the touch pulley is perpendicular to the belt.

3. Wiring

Wire to the contact output. No power supply required.

4. Adjustment

We will adjust the speed of the belt conveyor in advance before shipping, so there is no need for

on-site adjustment.

*For details, please refer to the instruction manual.

\ Download or Request to quote /

Model lineup

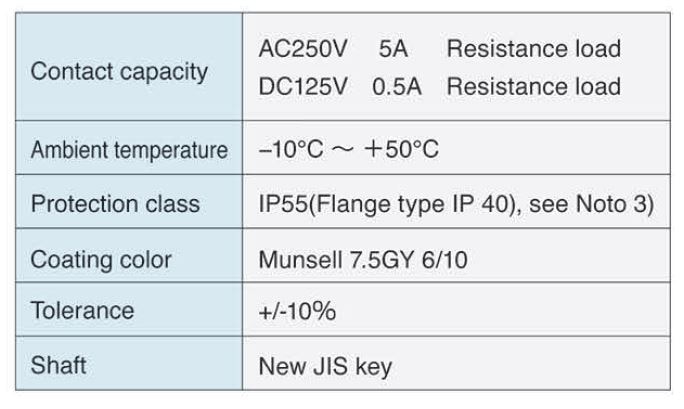

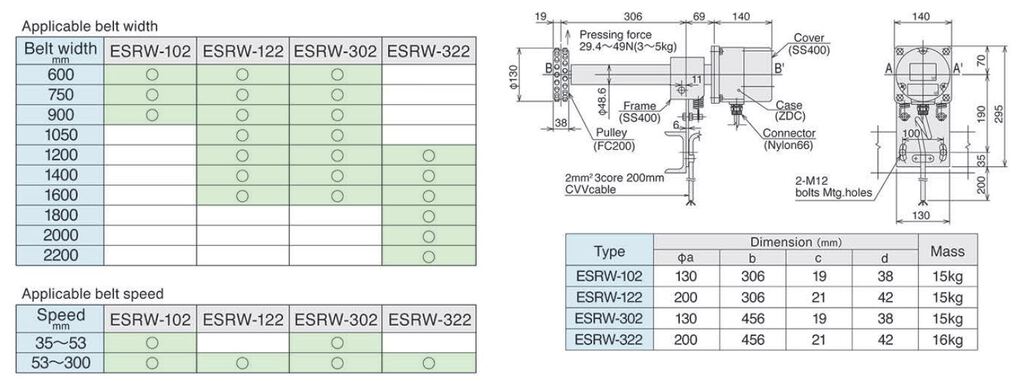

Common standard specifications

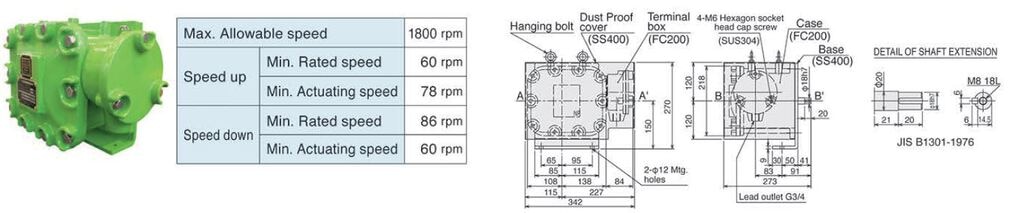

Dimensions(mm)

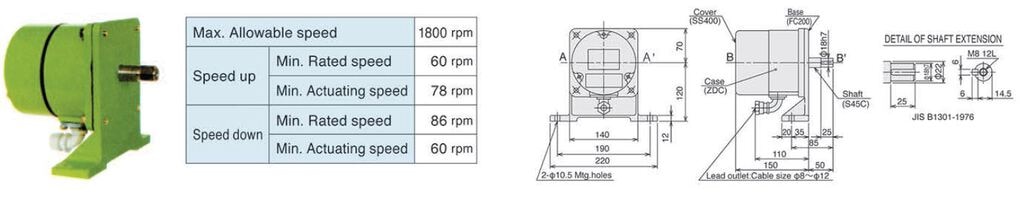

Touch roller type ESRW series

Flange-type ESRK-100 with shaft end key (mass 4.4kg)

Base type ESRB-100 with shaft end key (mass 7.0kg)

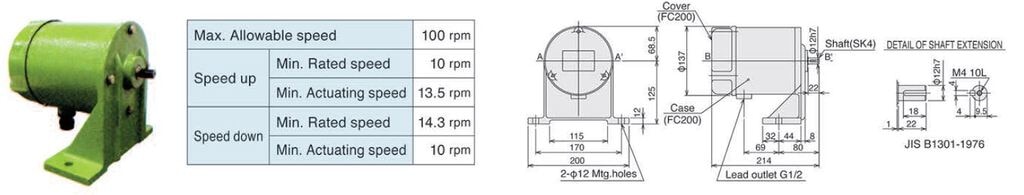

Low speed type ESRL-100 with shaft end key (mass 9.5kg)

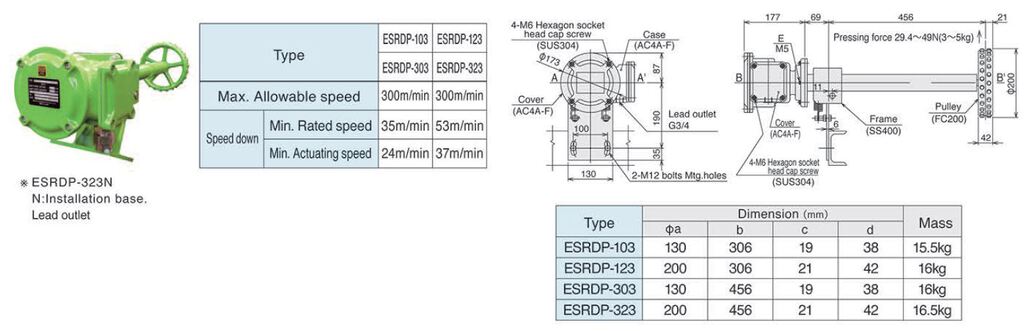

Dust-ignition proof type SDP13 Toucg roller type ESRDP series

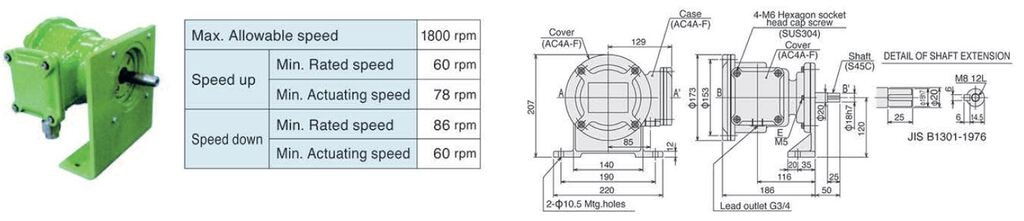

Dust-ignition proof type SDP13 Base type ESRDP-200B With shaft end key (7.5 kg)

Explosion proof type d2G4 Base-type ESRM-100B With shaft end key (37kg)

Note 1) A-A' and B-B' of the drawings should be horizontal from the viewpoint of internal structure.

Note 2) Specifications and external dimensions are subject to change for product improvement.

Note 3) Flange type can be used as IP55 by sealing the fron if the mounting base.

\ Download or Request to quote /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.