Belt Conveyor Protection Equipment

Speed switch constantly monitor shaft speed of conveyors and machinery to detect and signal slippage or overspeed.

Advantages

- Detecting belt slippage can prevent conveyor fires and chute clogging.

- Early detection of belt rupture minimizes chute clogging and cargo spillage.

\ Down load or Request for quote /

Features of the Speed Switch

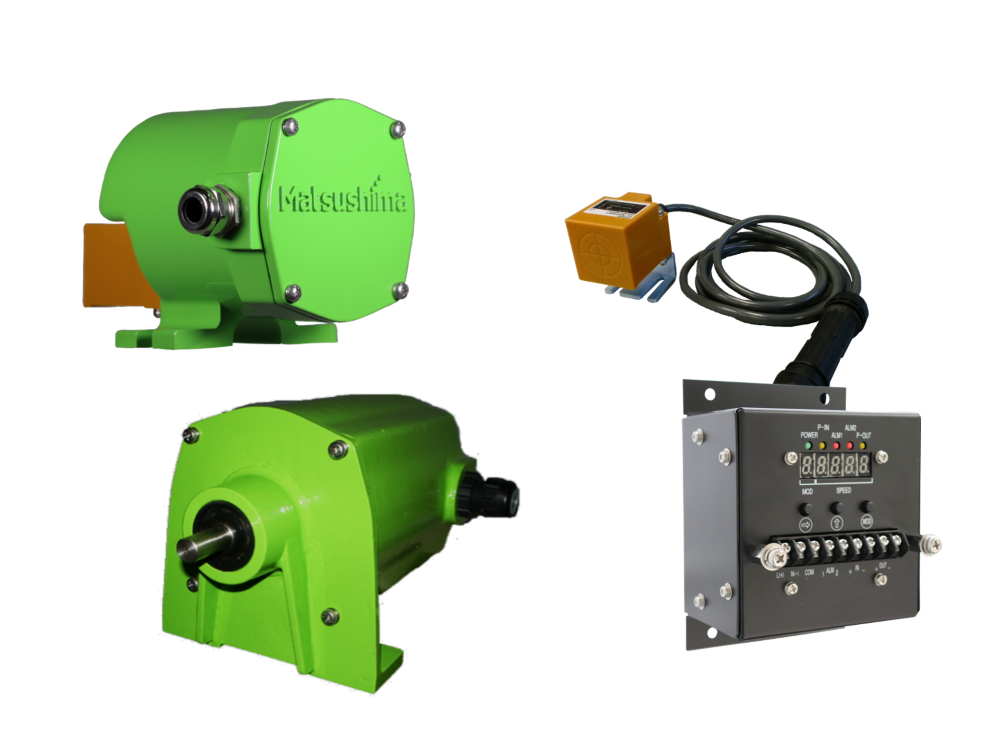

There are two types of Speed Switches. One is a one-push setting type and the other is an ultra-low speed rotation type. The characteristics of each are as follows.

<One-push setting type>

Contactless

detection

Proximity switches are used to measure speed without contact, and there are no consumables.

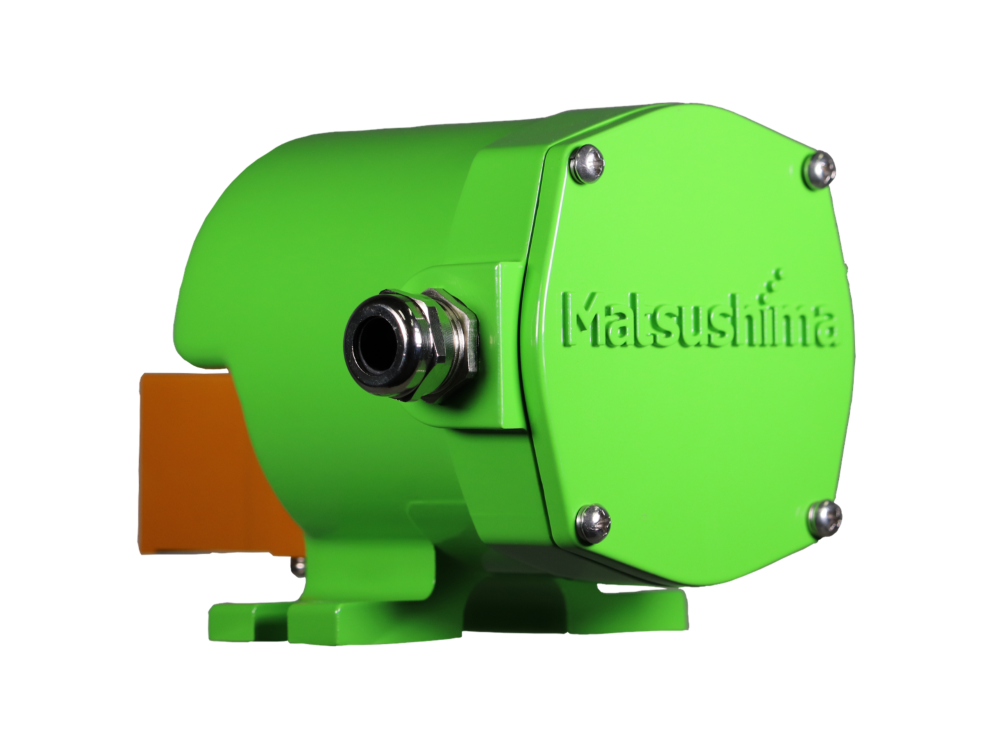

(Photo: ESPB-050)

<One-push setting type>

Easy one-push

adjustment

The one-push type automatically memorizes the number of revolutions just by pressing a button. If the speed drops by 5% or more from the memorized number of revolutions, it will be detected and notified. If necessary, you can freely change the setting value using the adjustment button.

<One-push setting type>

Extensive lineup

to suit

installation

environment

You can choose from four types according to installation environment.

Outdoor type, Separated proximity switch type, Transducer in-panel mounting type, Touch roller type

*Separatde type proximity switches can be extended up to 1km.

<Ultra-low speed rotation type>

Supports

ultra-low speed

rotation

An ultra-low speed rotation type that supports shaft speeds from 0.1 to 99.9 rpm is also available.

(Photo: ESKB-610M)

*For details, please refer to the instruction manual.

Operating principle

One push type

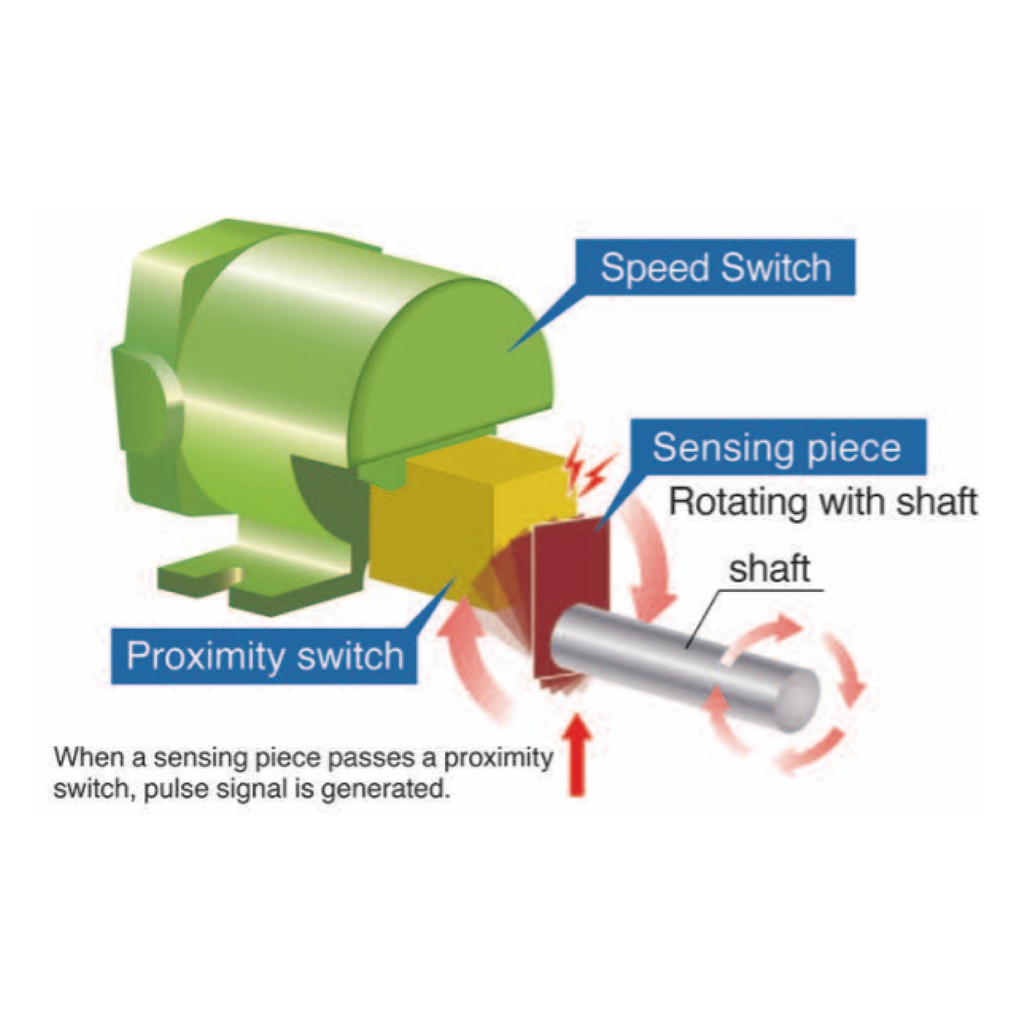

Non-contact measurement using a proximity switch.

A magnetic detection piece is attached to shaft of mechanical device, and a proximity switch is installed in front of the detection piece. As the shaft rotates, the detection piece passes in front of the proximity switch many times according to the rotation speed of the shaft. At this time, the proximity switch generates a pulse signal each time a piece of metal passes in front of it. The period of this pulse signal changes according to the rotation speed of the shaft, so the rotation speed can be measured.

Ultra low speed type

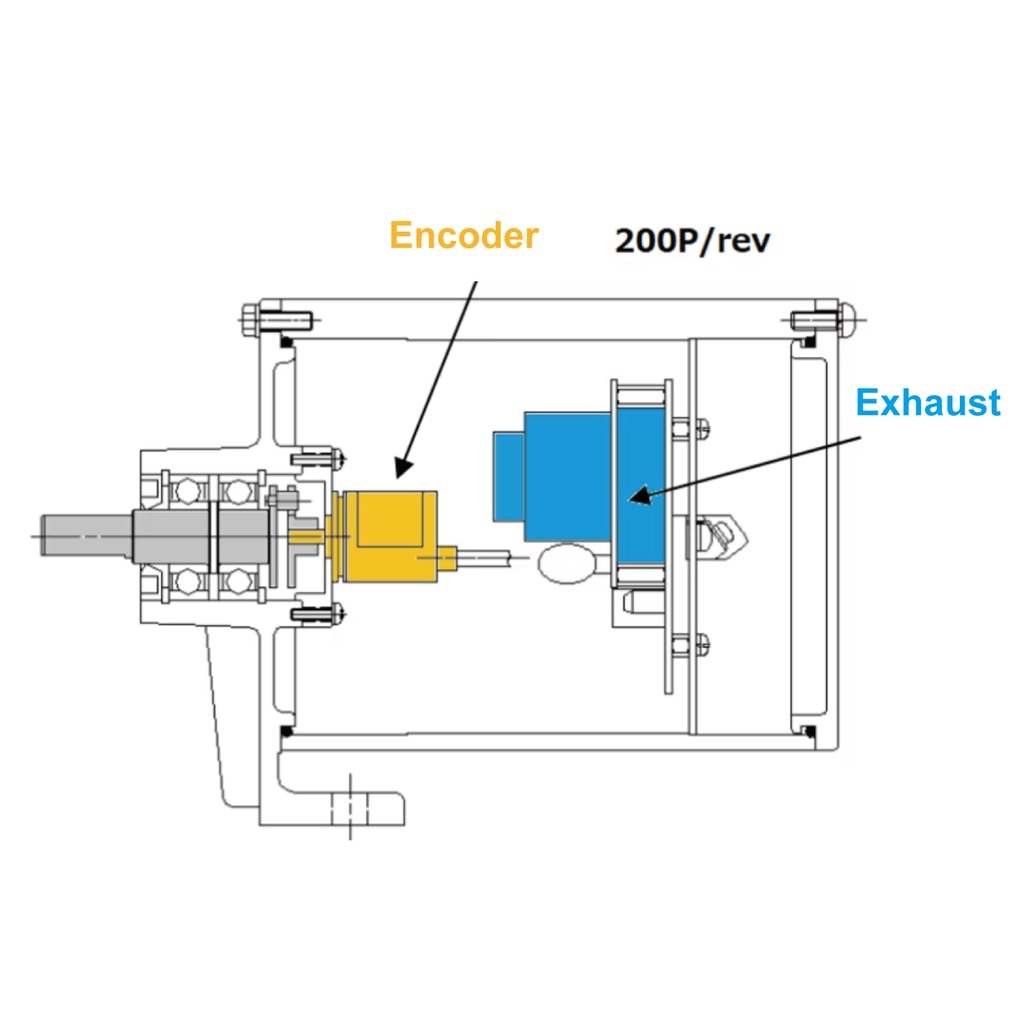

ESKB-610M

Built-in encoder detects low-speed rotation with high accuracy

Rotation from shaft is transmitted to internal encoder. The encoder pulses the number of revolutions with a high accuracy of 200P/rev. The pulse signal is converted to the number of revolutions in the converter.

Even an ultra-low rotation speed of 0.1 rpm is detected in 6 seconds, so it will not be too late to respond.

Of course, we also support overspeed detection.

How to use?

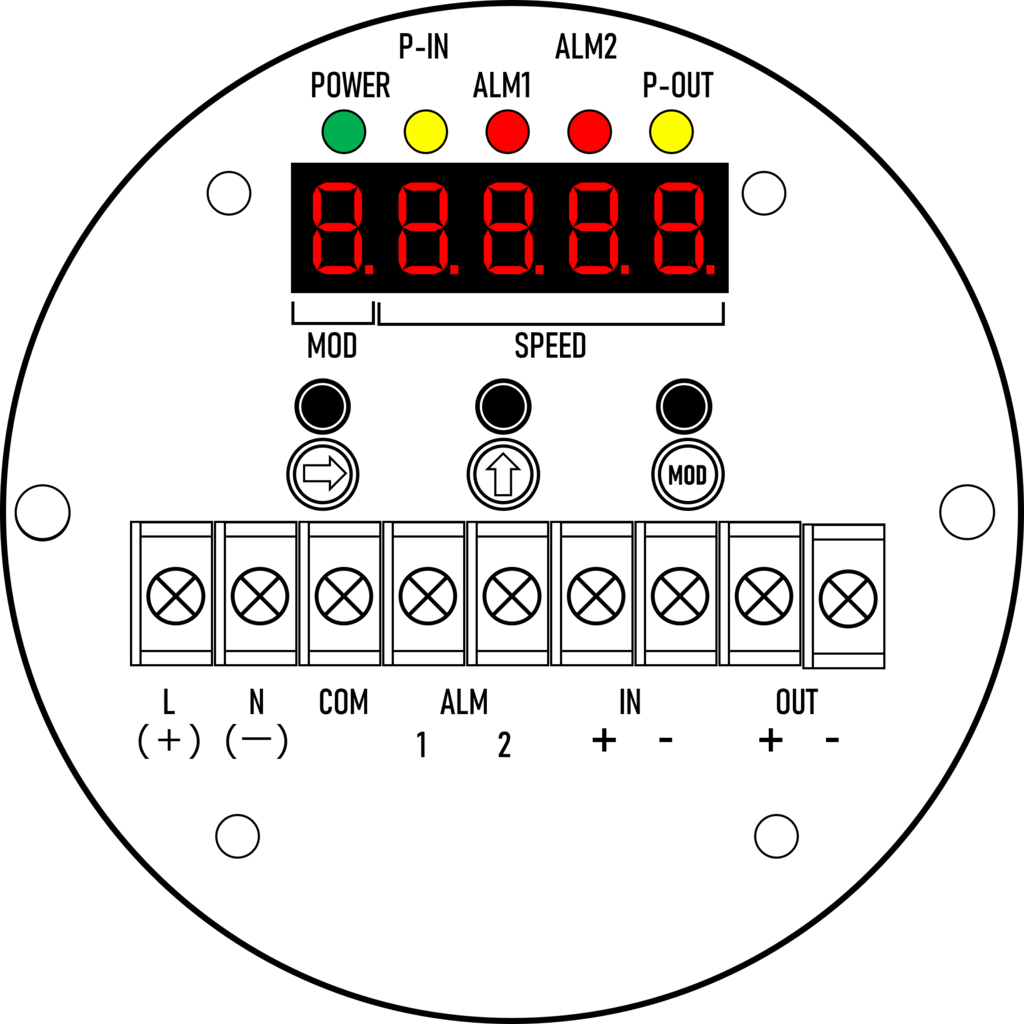

Ⅰ.One-push type

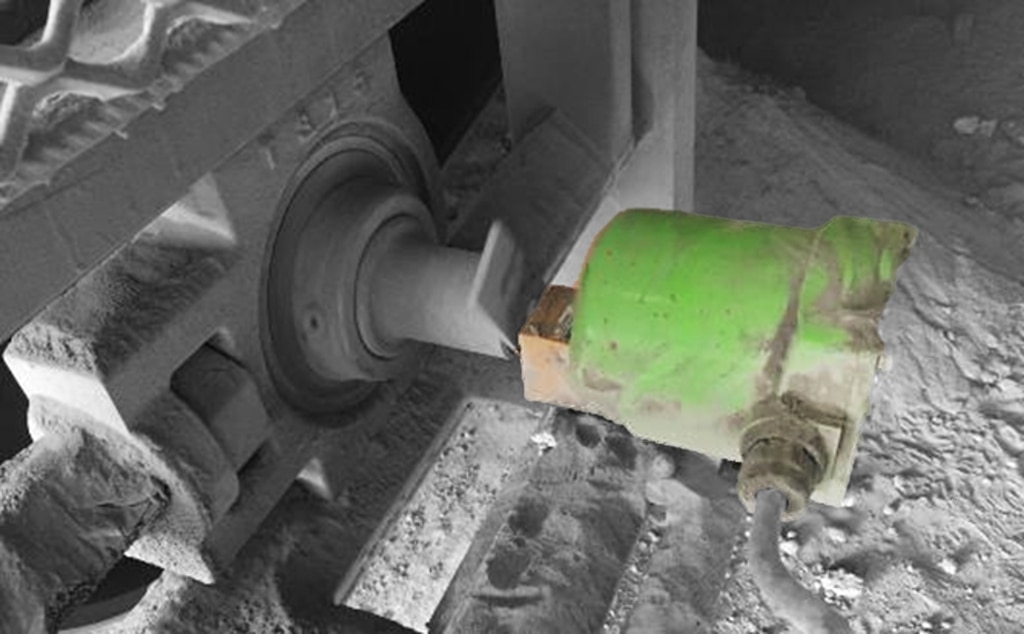

1.Determine mounting position

For proximity switches, find a spot on shaft where you can attach the sensing strip. If mounting position is narrow, select separated type. If touch roller method is selected, no detection piece is used. Please refer to the instruction manual for details.

2. Mounting

Before installing Speed Switch, fix detection piece (40 mm or more in width) to shaft by welding, etc. When attaching multiple detection pieces, place them evenly on the circumference. Also, keep the distance between the detection piece and the proximity switch within 18mm.

3. Wiring

Wire power supply and contact output.

4. Adjustment

The number of revolutions is automatically memorized with just one push of a button. If speed drops by 5% or more from the memorized number of revolutions, it will be detected and notified.

If necessary, change setting value with adjustment button.

*For details, please refer to the instruction manual.

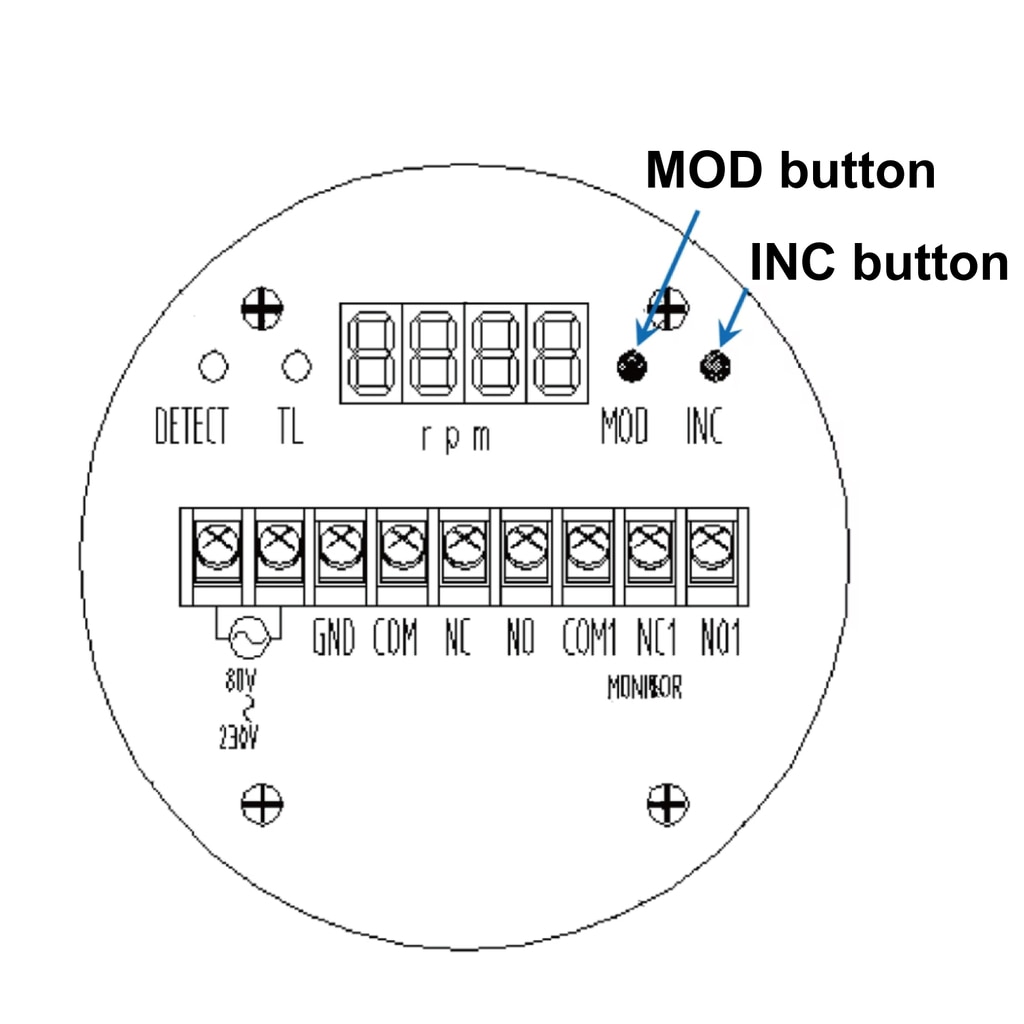

Ⅱ. Ultra-low speed type

1.Determine mounting position

Install in a place where there is little impact or vibration.

2. Mounting

Connect shaft on conveyor side and shaft of Speed Switch with a coupling or the like.

3. Wiring

Wire power supply and contact output.

4. Adjustment

Switch to measurement mode with the MOD button and enter the number of revolutions with the INC button.

\ Down load or Request for quote /

Maintenance

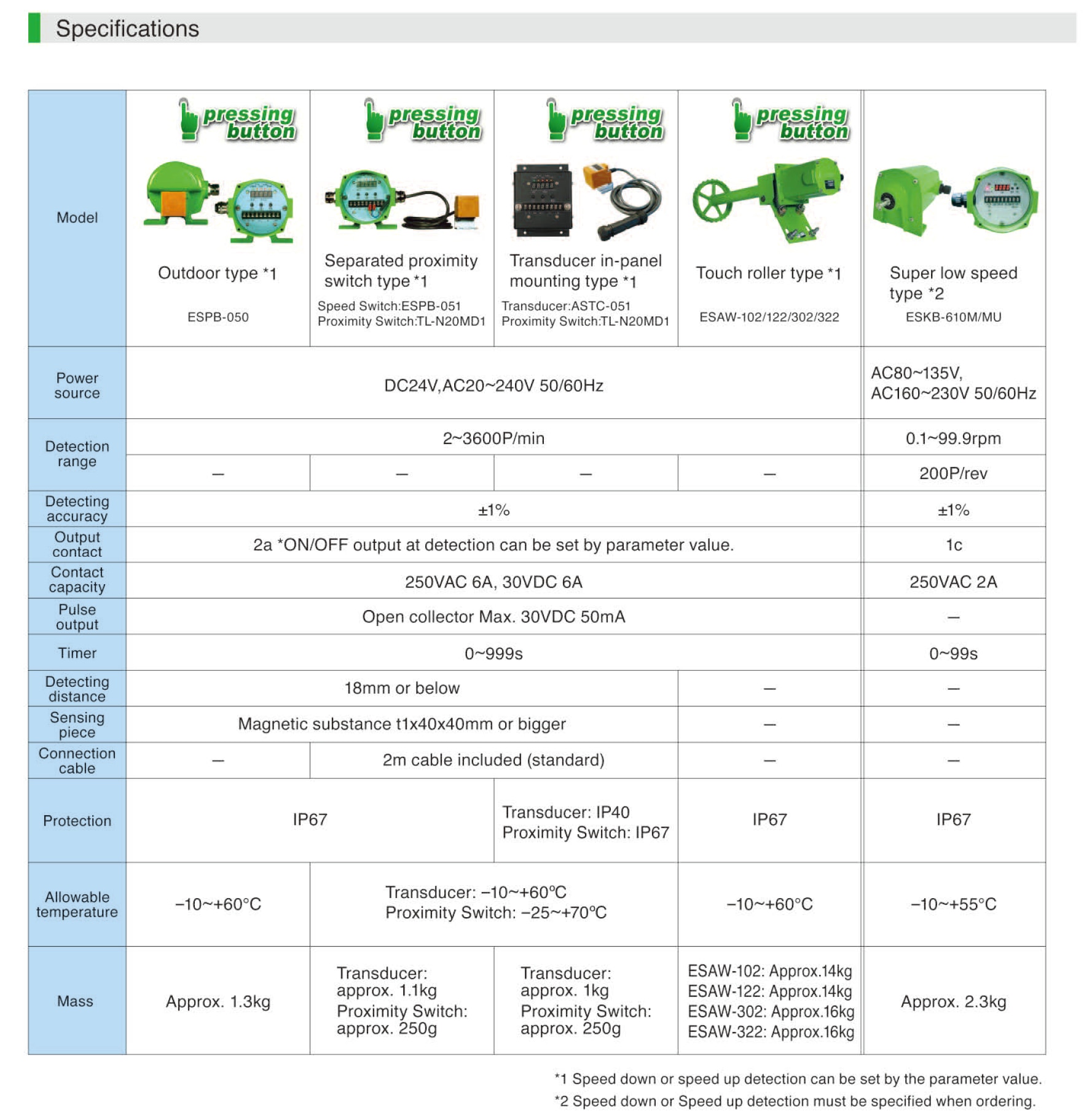

Model lineup

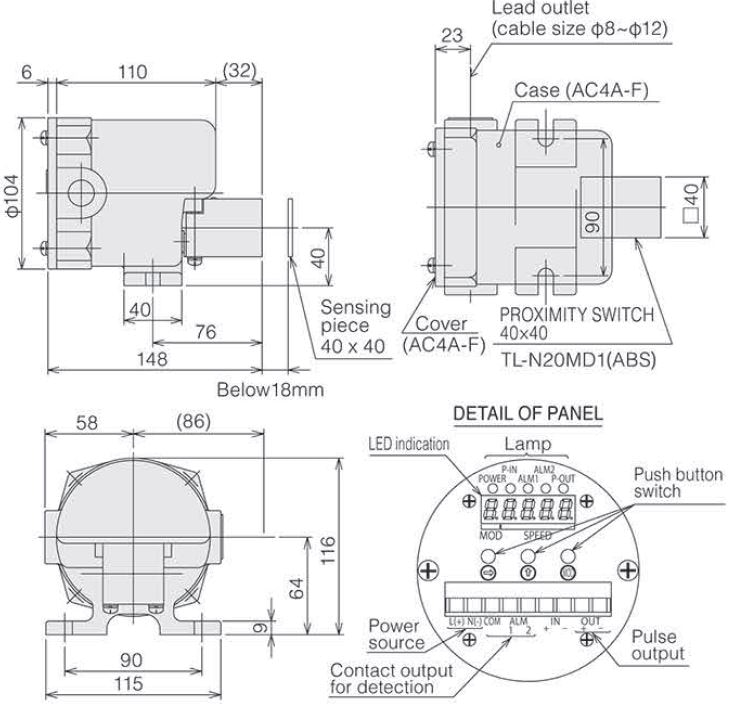

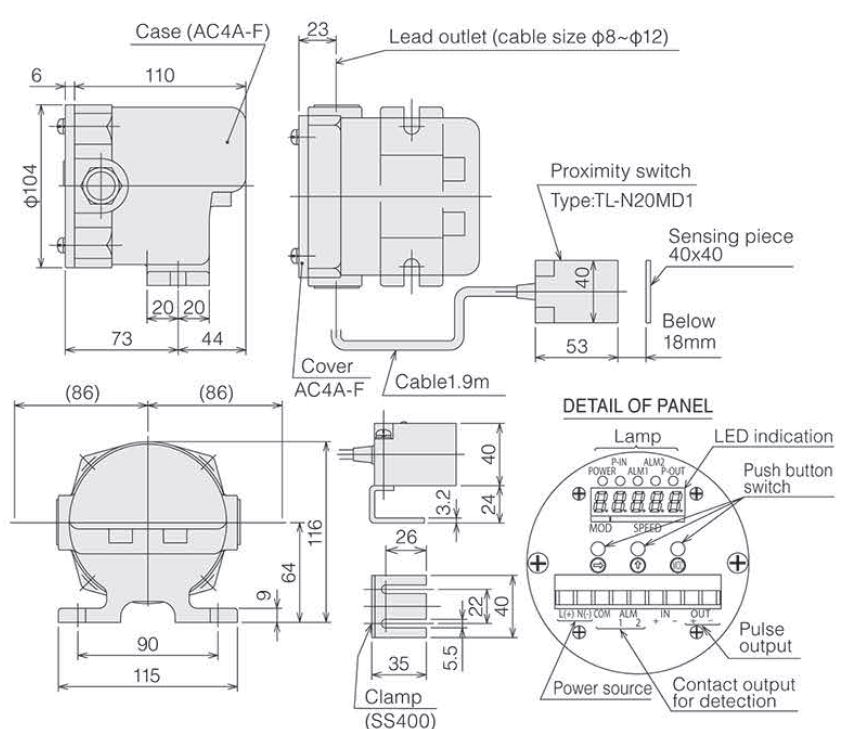

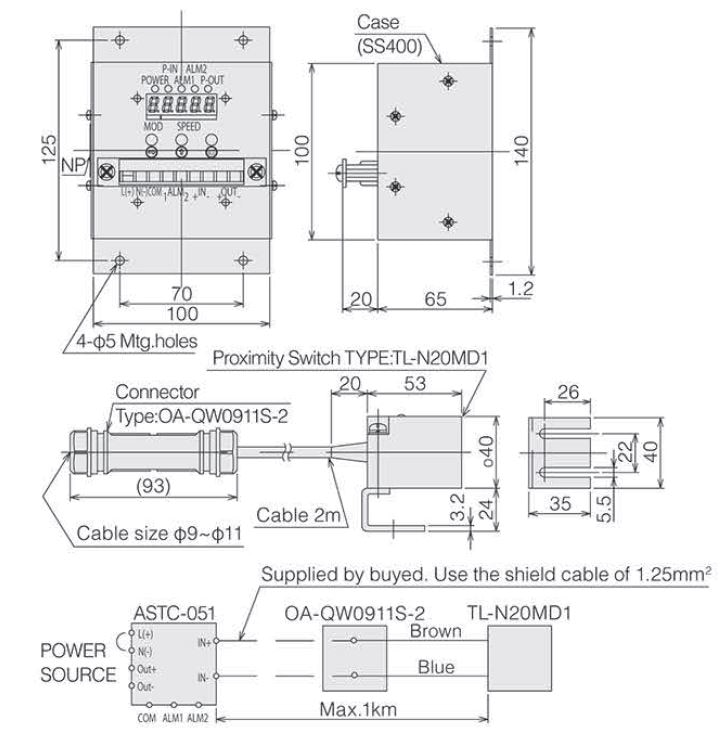

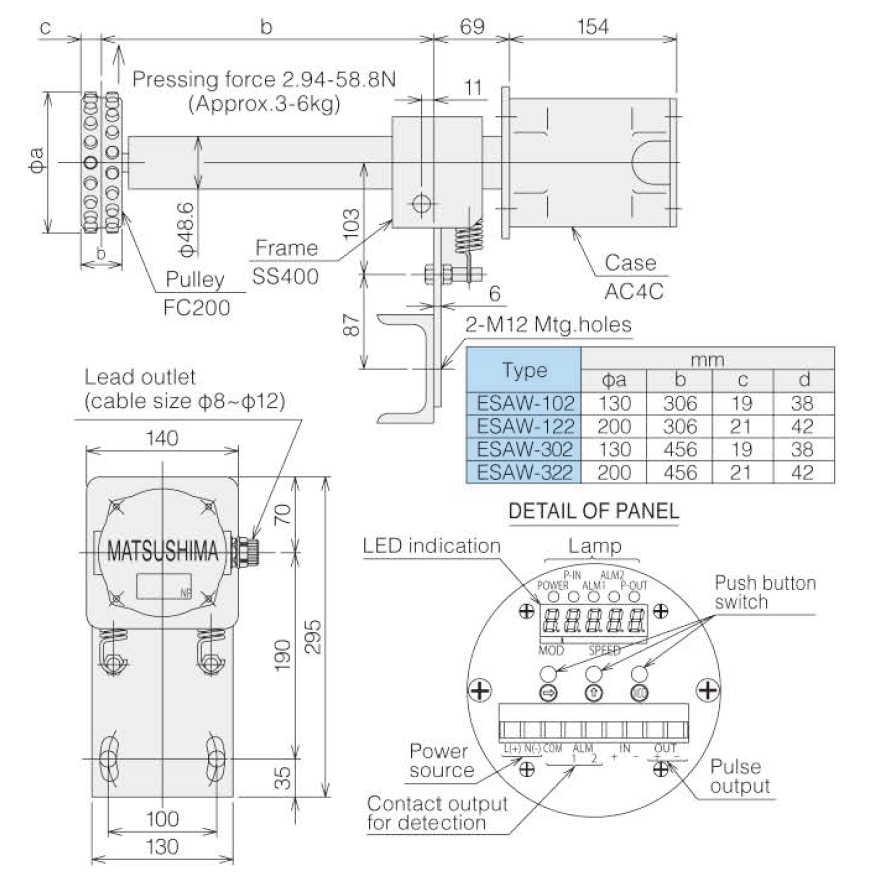

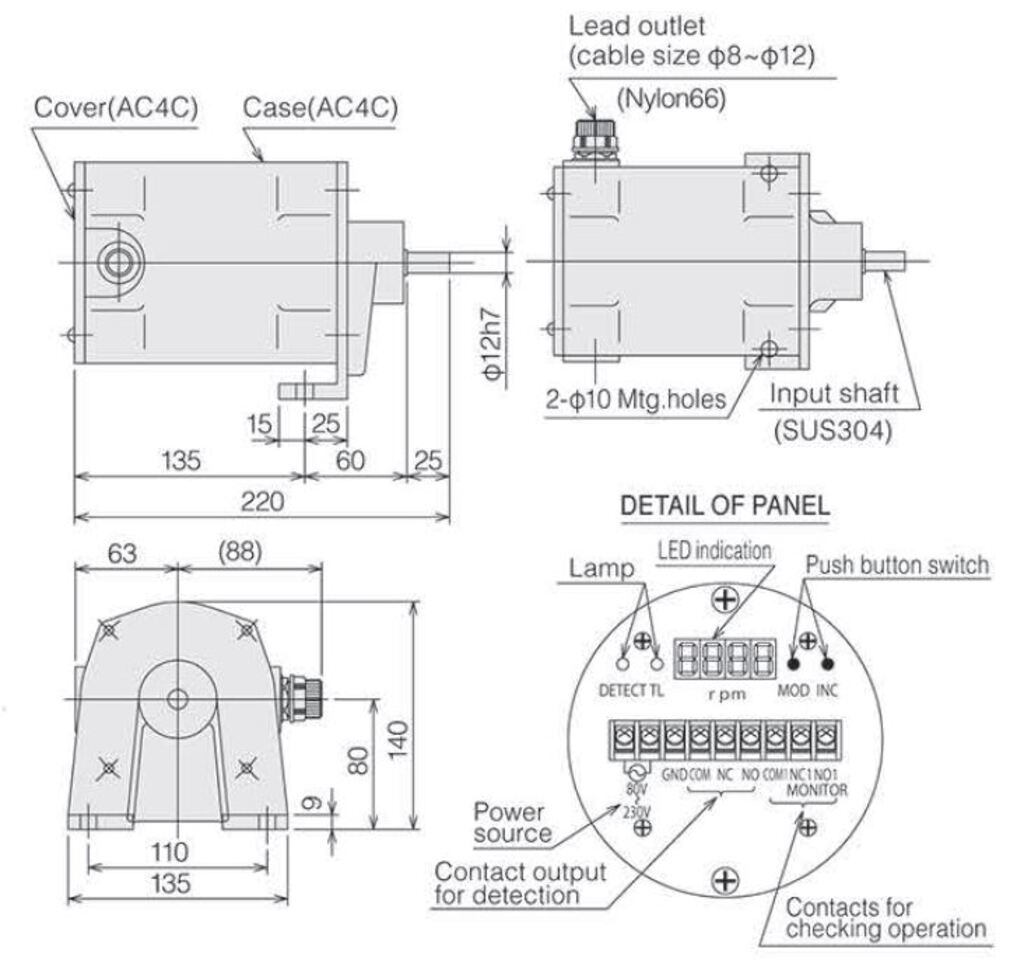

Dimensions(mm)

ESPB-050

ESPB-051/TL-N20MD1

ASTC-051/TL-N20MD1

ESAW-102/302

ESKB-610M/MU

\ Down load or Request for quote /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.