What is bulk density?

What is bulk density?

It is defined as the mass of the many particles of the soil material divided by the total volume they occupy.

The total volume includes particle volume, inter-particle void volume, and internal pore volume.

Importance on industrial processes

Bulk density is important as it has many useful roles in various industries and processes that handle powders and bulk solid materials.

Main reasons why bulk density is necessary and important are shown below:

Design and Manufacturing Process

1. Equipment Design

- It is essential for designing hopper and silo capacity.

- Used to determine the capacity of transportation equipment (e.g. conveyors).

2. Manufacturing process optimization

- Useful for determine the amount of raw materials charging and the mixing ratio.

- This contributes to product quality control and uniformity.

Logistics and Storage

1. Improving transport efficiency

- Used to calculate the load capacity of trucks and ships.

- It helps in estimating and optimizing transportation costs.

2. Storage space management

- It is important to calculate the required capacity of warehouses and storage facilities.

- It is used in inventory management and inventory turnover calculations.

Quality Control and Product Characteristics

1. Product Consistency

- It serves as an indicator to ensure uniformity between product lots.

- It is used for quality control of raw materials and incoming inspection.

2. Product Attribute Prediction

- It helps predict physical properties such as density and strength of the final product.

- It contributes to the evaluation of product performance and durability.

Economy and Efficiency

1. Cost Management

- This helps to accurately grasp the amount of raw materials purchased and used.

- It serves as the basis for calculating manufacturing costs and setting prices.

2. Energy efficiency

- It contributes to optimizing energy consumption in processes such as grinding and mixing.

- It also indirectly contributes to reducing the environmental impact.

Safety

1. Dust explosion risk assessment

- It is an important factor when assessing the risk of dust explosion.

- It is essential for planning and implementing safety measures.

2. Managing your working environment

- It is useful for predicting the amount of dust generated and its spread.

- This serves as basic data for occupational safety and health management.

Bulk density plays an important role in these diverse aspects.

Accurate measurement and proper use of bulk density brings many benefits such as efficient manufacturing processes, improved quality, cost reduction and safety.

For this reason, bulk density is widely recognized as an essential indicator in industries that handle powders and granular materials.

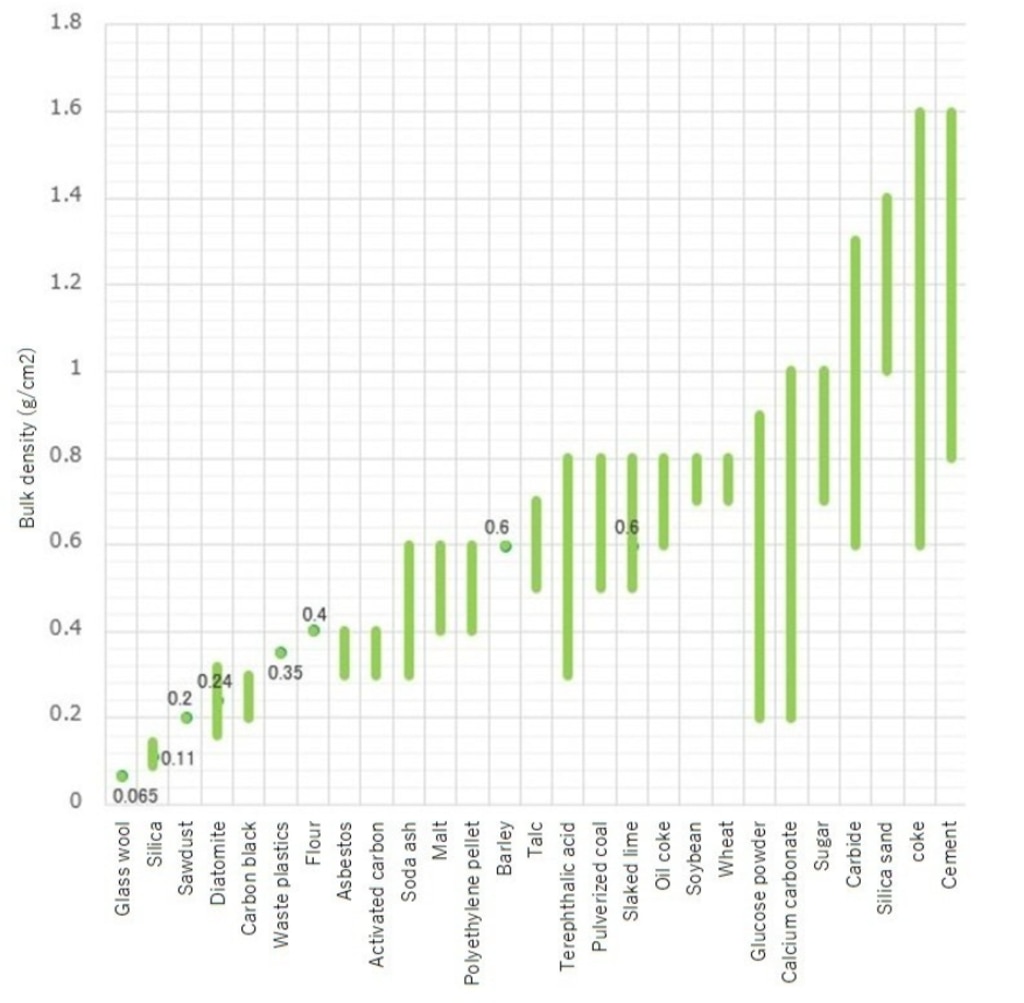

Bulk Density Chart for bulk material handling

Relating information and sensors

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.