What are Level Transmitters?

What are Level Transmitters?

Level Transmitters are sensors used to measure and monitors the level of liquid or bulk solids in tanks, silos, river water levels, tidal levels (sea level height), etc.

There are many types of level Transmitters. Not only do they differ in method, but each manufacturer has its own features. Selection should take into account key conditions such as physical properties, measurement environment, installation conditions, and disturbance. Here we introduce the principle, features, and disadvantages of each method.

There are many types of level Transmitters. Not only do they differ in method, but each manufacturer has its own features. Selection should take into account key conditions such as physical properties, measurement environment, installation conditions, and disturbance. Here we introduce the principle, features, and disadvantages of each method.

The role of "Level Transmitters" and "Level Switches" in industry

Level Transmitters are used in mass-producing factories, such as material industry, to measure amount stored in silos and tanks that store raw materials and products.

In factories, it is necessary to continuously send raw materials to next process so that production does not stop. Therefore, it is necessary to replenish raw materials before storage capacity in the silo runs out so that production can continue.

It would be extremely inefficient to monitor levels of each of these facilities individually, so level meters are used to monitor and automate (control) storage levels.

In factories, it is necessary to continuously send raw materials to next process so that production does not stop. Therefore, it is necessary to replenish raw materials before storage capacity in the silo runs out so that production can continue.

It would be extremely inefficient to monitor levels of each of these facilities individually, so level meters are used to monitor and automate (control) storage levels.

What is the difference between Level Transmitter and Level Switch?

There are two main types of sensors for level measurement. "Level Transmitter" and "Level Switch".

What is a Level Transmitter?

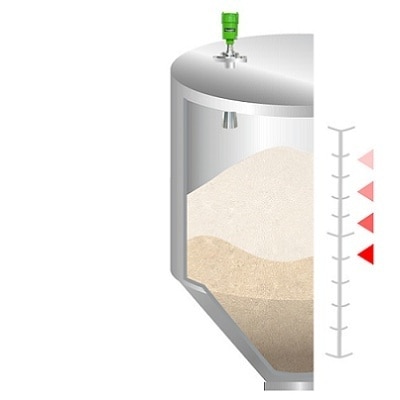

The amount stored in container is continuously measured and displayed as **%, level **m, etc., and is used as an approximate storage level.

The measured value is converted from 0 to 100% into an instrumentation signal of 4 to 20 mA DC or 1 to 5 V and output, which is used for monitoring and control.

The measured value is converted from 0 to 100% into an instrumentation signal of 4 to 20 mA DC or 1 to 5 V and output, which is used for monitoring and control.

What is Level Switch?

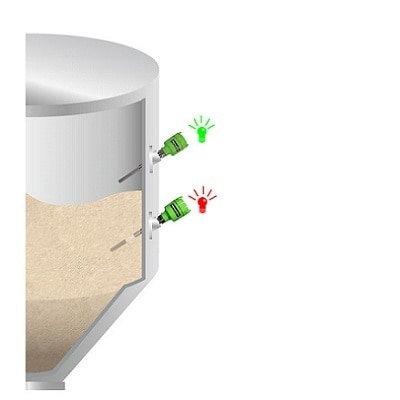

This is a switch that detects when the container is full or empty by installing a sensor at the full or empty position.

It is used as a signal to start and stop loading and unloading raw materials, etc.

When detected, it outputs an ON or OFF contact signal.

It is used as a signal to start and stop loading and unloading raw materials, etc.

When detected, it outputs an ON or OFF contact signal.

How to use Level Transmitter and Level Switch?

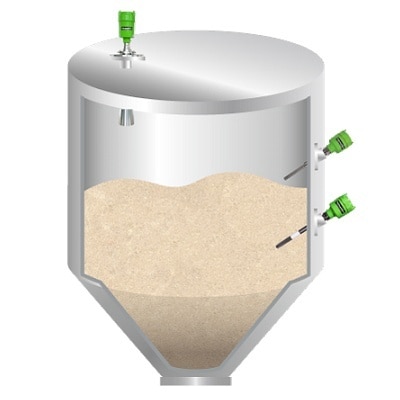

Small containers are often controlled with just a Level Switch, but for medium-sized and large containers, instead of installing multiple Level Switches at the top, middle, and bottom, a Level Transmitter is used to continuously measure the storage level and calculate approximate storage level in real time.

It is often displayed and used.

In some cases, Level Transmitter is also used to check the intermediate storage amount while controlling with a Level Switch.

This also has the advantage of making it easier to notice if there is a problem with a certain sensor.

Since it can be detected early, it can reduce impact on production process and prevent stress on equipment.

It is often displayed and used.

In some cases, Level Transmitter is also used to check the intermediate storage amount while controlling with a Level Switch.

This also has the advantage of making it easier to notice if there is a problem with a certain sensor.

Since it can be detected early, it can reduce impact on production process and prevent stress on equipment.

[Level meters and level switches depending on the purpose and environment]

There are many types of level meters and level switches depending on the object to be measured and the measurement environment. Please check the measurement object and environment to be used and select the one that matches. Also, not everything will match. In such cases, there are many cases where special specifications are available, so please contact the manufacturer in such cases. Please refer to the information below that will help you select a model.

There are many types of level meters and level switches depending on the object to be measured and the measurement environment. Please check the measurement object and environment to be used and select the one that matches. Also, not everything will match. In such cases, there are many cases where special specifications are available, so please contact the manufacturer in such cases. Please refer to the information below that will help you select a model.

Types of Level Transmitters

There are various types of Level Transmitters.

Have you ever thought you understood characteristics of each model, but when it came time to choose a model, you were confused as to which one to choose?

For those people, here we will explain not only types and features of Level Transmitters, but also their disadvantages.

At the end, we have prepared a quick reference table for model selection, so please use it.

Have you ever thought you understood characteristics of each model, but when it came time to choose a model, you were confused as to which one to choose?

For those people, here we will explain not only types and features of Level Transmitters, but also their disadvantages.

At the end, we have prepared a quick reference table for model selection, so please use it.

Not only do Level Meters have different methods, but each manufacturer also has its own features.

It is necessary to consider major conditions such as physical properties, measurement environment, installation conditions, and external disturbances when making a selection.

Raw materials and products come in various states such as bulk, granular, powder, liquid, slurries, and deposits in liquid, and there are many measurement methods that take into consideration physical properties and environmental factors.

Additionally, Level Meters can be roughly divided into two types: methods that measure the empty distance from tank ceiling to object to be measured, and methods that directly measure storage level of the object to be measured.

Level meters that measure air distance are sounding, ultrasonic, microwave, laser distance meter, guide rope type, liquid level meter, and displacer.

Capacitance, pressure, and differential pressure gauges directly measure storage level.

Here, we will introduce principles, features, and disadvantages of each method, focusing on measuring powder, granular, and bulk.

It is necessary to consider major conditions such as physical properties, measurement environment, installation conditions, and external disturbances when making a selection.

Raw materials and products come in various states such as bulk, granular, powder, liquid, slurries, and deposits in liquid, and there are many measurement methods that take into consideration physical properties and environmental factors.

Additionally, Level Meters can be roughly divided into two types: methods that measure the empty distance from tank ceiling to object to be measured, and methods that directly measure storage level of the object to be measured.

Level meters that measure air distance are sounding, ultrasonic, microwave, laser distance meter, guide rope type, liquid level meter, and displacer.

Capacitance, pressure, and differential pressure gauges directly measure storage level.

Here, we will introduce principles, features, and disadvantages of each method, focusing on measuring powder, granular, and bulk.

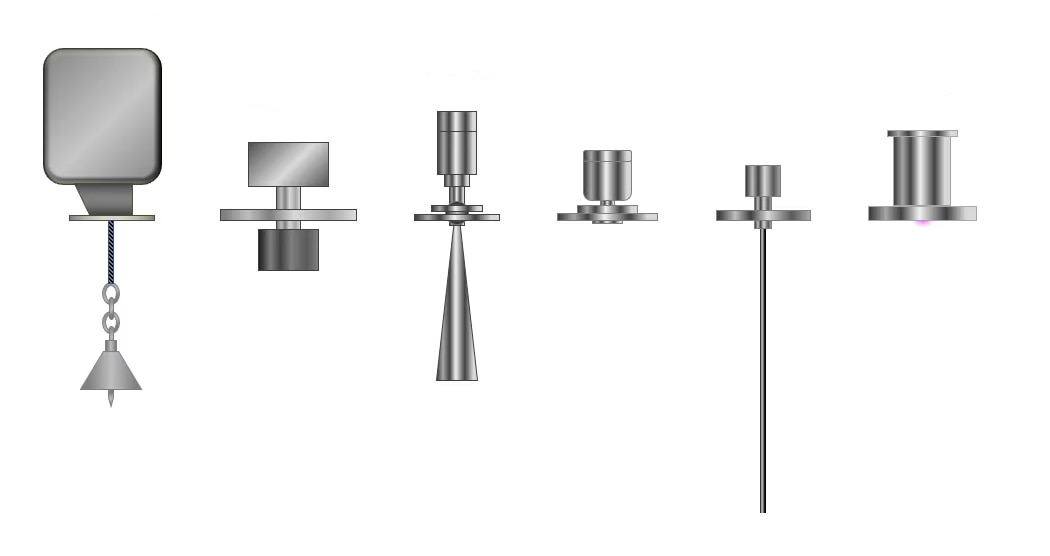

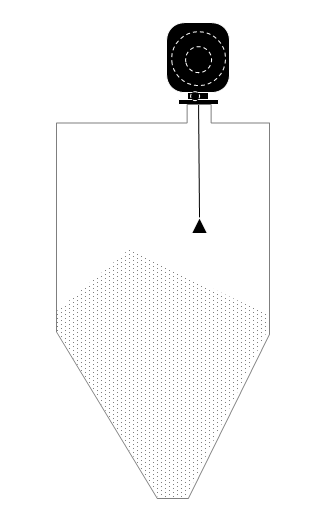

1. Sounding Level Transmitter (weight type)

■Principle

Measurements are taken by electrically lowering a weight suspended from a wire rope until it touches object to be measured. The time from start of measurement until weight hits ground is measured and converted to empty distance. (Distance = Speed x Time)

■Features

- Easy to understand as it is measured physically.

- Even if a large amount of dust or steam is generated, it will not affect measurement.

- Can also be used to detect deposits in liquid.

■Disadvantages

- It requires consumables such as wire rope, so it is less easy to maintain.

-Be careful when using in areas where foreign objects are prohibited as it comes into contact with object to be measured.

Matsushima Measure Tech Co.,Ltd. offers the following lineup.

Measurements are taken by electrically lowering a weight suspended from a wire rope until it touches object to be measured. The time from start of measurement until weight hits ground is measured and converted to empty distance. (Distance = Speed x Time)

■Features

- Easy to understand as it is measured physically.

- Even if a large amount of dust or steam is generated, it will not affect measurement.

- Can also be used to detect deposits in liquid.

■Disadvantages

- It requires consumables such as wire rope, so it is less easy to maintain.

-Be careful when using in areas where foreign objects are prohibited as it comes into contact with object to be measured.

Matsushima Measure Tech Co.,Ltd. offers the following lineup.

Matsushima Measure Tech Co.,Ltd. offers the following lineup.

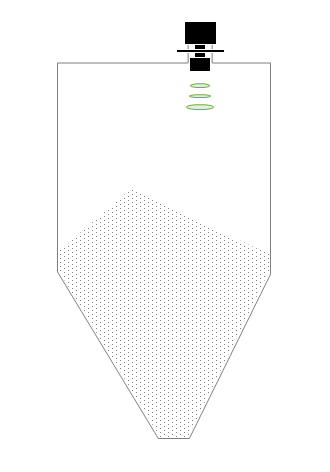

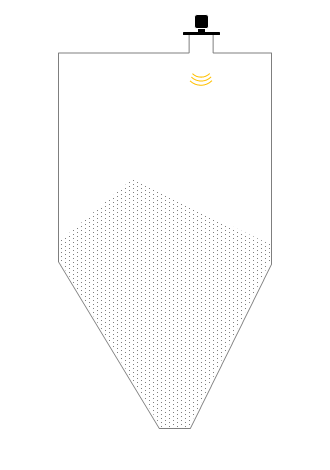

2. Ultrasonic Level Transmitter

■Principle

This is a non-contact level meter. The time it takes for an ultrasonic pulse to be emitted from the sensor, reflected from the object to be measured, and returned to the sensor is measured and converted into an empty distance.

■Features

- Non-contact level measurement is possible at a relatively low cost. ・Since it has directivity, it is suitable for measurements in narrow spaces.

■Disadvantages

: There are limits to measurement in environments where dust and steam are generated. - If there is a temperature gap or generation of gas within the measurement area, the speed of sound may change and the error may increase.

This is a non-contact level meter. The time it takes for an ultrasonic pulse to be emitted from the sensor, reflected from the object to be measured, and returned to the sensor is measured and converted into an empty distance.

■Features

- Non-contact level measurement is possible at a relatively low cost. ・Since it has directivity, it is suitable for measurements in narrow spaces.

■Disadvantages

: There are limits to measurement in environments where dust and steam are generated. - If there is a temperature gap or generation of gas within the measurement area, the speed of sound may change and the error may increase.

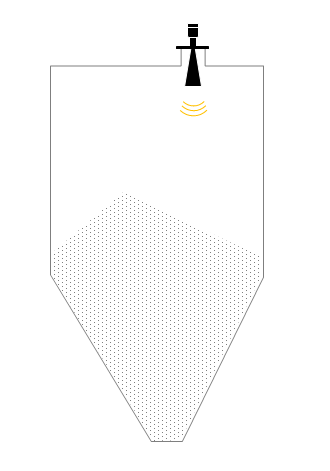

3. Radar Level Transmitter (Pulse radar type)

■Principle

Radio wave level meters, also called Radar Level Transmitter, are non-contact level meters. Microwave pulses are emitted from sensor, and time taken for pulses to be reflected from object to be measured and returned to sensor is measured and converted to empty scale distance.

■Features

- Because it uses radio waves, it is not affected by temperature or gas.

- Radio waves are transparent, so they are not easily affected by dust or steam.

■Disadvantage

- Measurement objects with low dielectric constants may not be able to be measured due to weak reflected waves passing through them.

Example: silica

Radio wave level meters, also called Radar Level Transmitter, are non-contact level meters. Microwave pulses are emitted from sensor, and time taken for pulses to be reflected from object to be measured and returned to sensor is measured and converted to empty scale distance.

■Features

- Because it uses radio waves, it is not affected by temperature or gas.

- Radio waves are transparent, so they are not easily affected by dust or steam.

■Disadvantage

- Measurement objects with low dielectric constants may not be able to be measured due to weak reflected waves passing through them.

Example: silica

★ Following useful information has also been viewed in relation to Radar Level Transmitter

4. Radar Level Transmitter (FMCW type)

■Principle

This is non-contact level meter. Frequency modulated microwaves are continuously emitted from sensor. Phase difference when the microwave reflected from object to be measured returns to sensor is converted into distance.

■Features

- Because it uses radio waves, it is not affected by temperature or gas.

-Because it is permeable, it is less affected by dust and steam.

- It has directivity and is suitable for measurements in narrow spaces.

■Disadvantages

- Measurement objects with low dielectric constants may not be able to be measured due to weak reflected waves passing through them.

Example: silica

This is non-contact level meter. Frequency modulated microwaves are continuously emitted from sensor. Phase difference when the microwave reflected from object to be measured returns to sensor is converted into distance.

■Features

- Because it uses radio waves, it is not affected by temperature or gas.

-Because it is permeable, it is less affected by dust and steam.

- It has directivity and is suitable for measurements in narrow spaces.

■Disadvantages

- Measurement objects with low dielectric constants may not be able to be measured due to weak reflected waves passing through them.

Example: silica

★ Following useful information has also been viewed in relation to Radar Level Transmitter

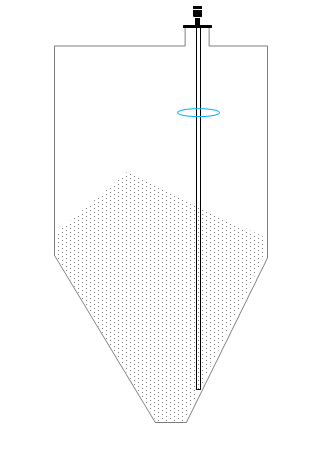

5. Guided Wave Radar Level Transmitter

■Principle

Microwave pulse is emitted along a rope hanging from the tank ceiling into the tank, and time it takes for microwave to reflect from object to be measured and return to sensor is measured and converted into an air distance.

■Features

- Unlike ultrasonic waves and non-contact microwaves, there is no radiation angle, making it suitable for installation in narrow spaces.

■Disadvantages

- Severe adhesion to the probe may result in erroneous measurements.

- If wire kinks, wire breaks, or adhesion occurs, noise will be reflected, making it easier to make incorrect measurements.

Microwave pulse is emitted along a rope hanging from the tank ceiling into the tank, and time it takes for microwave to reflect from object to be measured and return to sensor is measured and converted into an air distance.

■Features

- Unlike ultrasonic waves and non-contact microwaves, there is no radiation angle, making it suitable for installation in narrow spaces.

■Disadvantages

- Severe adhesion to the probe may result in erroneous measurements.

- If wire kinks, wire breaks, or adhesion occurs, noise will be reflected, making it easier to make incorrect measurements.

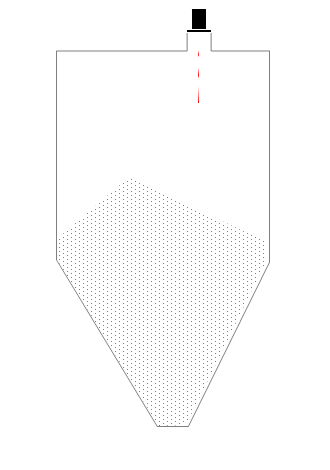

6. Laser Level Transmitter (Laser distance meter)

■Principle

There are two types of non-contact level meters.

[TOF method]

The time it takes for a laser pulse to be emitted from the sensor, reflected from the object to be measured, and returned to the sensor is measured and converted into an empty distance.

[Phase difference detection method]

An amplitude-modulated laser is emitted from the sensor. The phase difference between reflection from the measurement object and return to the sensor is converted to the empty distance.

■Features

- Directivity allows measurement in narrow spaces, and some can measure several hundred meters.

- The TOF method uses a relatively safe laser (class 1) and has high-speed response.

-The phase difference detection method has high accuracy and resolution.

■Disadvantages

- In environments where dust or steam is generated, the laser will diffuse and cannot be measured.

- Due to its directivity, if the object to be measured is flat like a mirror and has an angle of repose, the reflected waves tend to be weak and cannot be measured.

*Please note that phase difference detection method tends to be of a high class laser and requires safety management in many cases.

There are two types of non-contact level meters.

[TOF method]

The time it takes for a laser pulse to be emitted from the sensor, reflected from the object to be measured, and returned to the sensor is measured and converted into an empty distance.

[Phase difference detection method]

An amplitude-modulated laser is emitted from the sensor. The phase difference between reflection from the measurement object and return to the sensor is converted to the empty distance.

■Features

- Directivity allows measurement in narrow spaces, and some can measure several hundred meters.

- The TOF method uses a relatively safe laser (class 1) and has high-speed response.

-The phase difference detection method has high accuracy and resolution.

■Disadvantages

- In environments where dust or steam is generated, the laser will diffuse and cannot be measured.

- Due to its directivity, if the object to be measured is flat like a mirror and has an angle of repose, the reflected waves tend to be weak and cannot be measured.

*Please note that phase difference detection method tends to be of a high class laser and requires safety management in many cases.

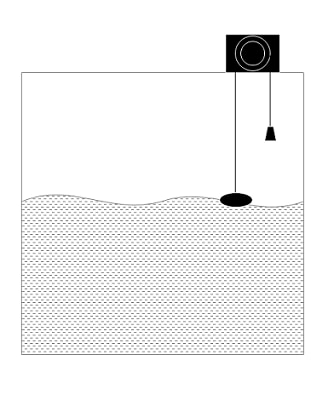

7. Float Level Transmitter

■Principle

A float suspended from stainless steel tape is floated on liquid surface and follows fluctuations in liquid level. Empty distance is measured by constantly measuring the length of the tape.

There are float spring balance type, sealed pipe type, and counterweight type.

■Features

- Simple structure, widely used for detecting liquid levels in large and small tanks due to its accuracy and durability.

■Disadvantages

- Easily affected by adhesion.

- Lack of maintainability as there are many fire extinguishing supplies.

- Errors may occur due to accumulation of solids on float.

- When used inside a breakwater pipe, float may not move properly due to adhesion and may malfunction.

A float suspended from stainless steel tape is floated on liquid surface and follows fluctuations in liquid level. Empty distance is measured by constantly measuring the length of the tape.

There are float spring balance type, sealed pipe type, and counterweight type.

■Features

- Simple structure, widely used for detecting liquid levels in large and small tanks due to its accuracy and durability.

■Disadvantages

- Easily affected by adhesion.

- Lack of maintainability as there are many fire extinguishing supplies.

- Errors may occur due to accumulation of solids on float.

- When used inside a breakwater pipe, float may not move properly due to adhesion and may malfunction.

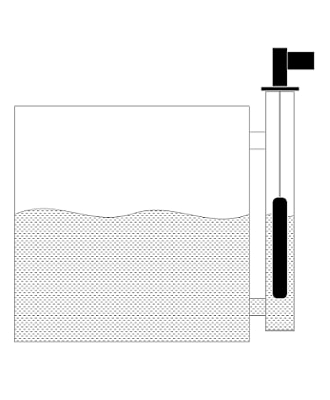

8. Displacer Level Transmitter

■Principle

Displacer is a float that is made heavier than specific gravity of object (liquid) to be measured and designed to sink into object.

The buoyancy of displacer suspended in liquid changes in proportion to changes in liquid level.

This change is mechanically captured and converted into a level.

■Features

- Low specific gravity, effective for liquid level measurement in high pressure environments.

■Disadvantages

- Measuring range is short at 300mm and 3000mm.

- It will malfunction if it gets stuck or gets caught in dirt.

- The spring is a consumable item.

- Recalibration is required in environments where liquid density of measured object changes.

Displacer is a float that is made heavier than specific gravity of object (liquid) to be measured and designed to sink into object.

The buoyancy of displacer suspended in liquid changes in proportion to changes in liquid level.

This change is mechanically captured and converted into a level.

■Features

- Low specific gravity, effective for liquid level measurement in high pressure environments.

■Disadvantages

- Measuring range is short at 300mm and 3000mm.

- It will malfunction if it gets stuck or gets caught in dirt.

- The spring is a consumable item.

- Recalibration is required in environments where liquid density of measured object changes.

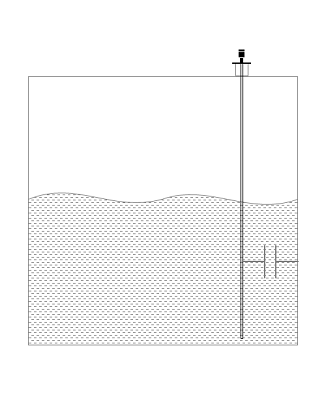

9. Capacitance Level Transmitter

■Principle

Capacitor is formed by probe electrode hanging from tank ceiling into tank and tank wall.

When object to be measured enters between electrodes, capacitance changes in proportion to the amount.

This is measured and converted into a storage level.

■Features

- Suitable for measurements in narrow spaces.

■Disadvantages

- Since it is a contact type, there is a possibility of contamination by foreign matter.

- It is necessary to empty tank and perform zero adjustment.

- Errors occur when measuring objects whose relative permittivity changes.

Capacitor is formed by probe electrode hanging from tank ceiling into tank and tank wall.

When object to be measured enters between electrodes, capacitance changes in proportion to the amount.

This is measured and converted into a storage level.

■Features

- Suitable for measurements in narrow spaces.

■Disadvantages

- Since it is a contact type, there is a possibility of contamination by foreign matter.

- It is necessary to empty tank and perform zero adjustment.

- Errors occur when measuring objects whose relative permittivity changes.

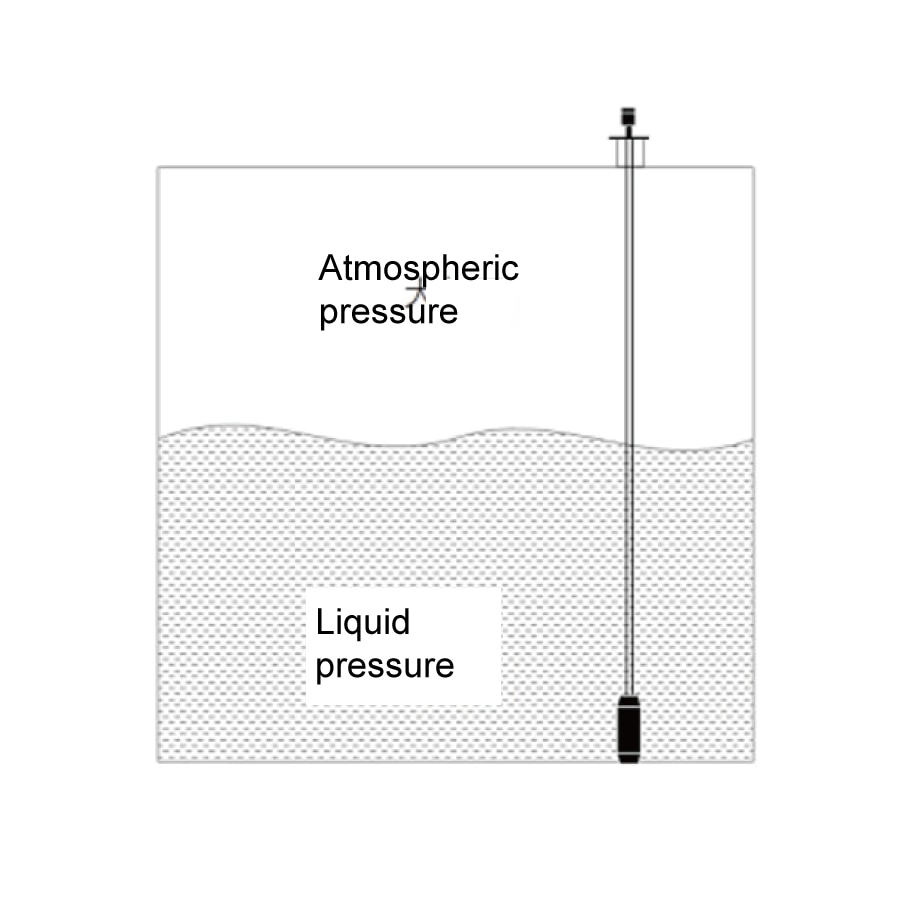

10. Pressure Level Transmitter

■Principle

Diaphragm captures changes in liquid pressure due to liquid level and converts it into storage level.

However, it must be used under condition that pressure inside the tank is atmospheric pressure.

■Features

- Easy to install even in places with limited installation space.

■Disadvantages

- If there are many foams in liquid, pressure will be uneven and accuracy will deteriorate.

- Accuracy will deteriorate if there is a lot of adhesion or sedimentation of solid matter.

- If a lot of air foams are generated, liquid pressure will be uneven and measured value will be incorrect.

- As liquid pressure changes depending on specific gravity of liquid, adjustment is required.

- When performing maintenance, tank must be emptied.

Diaphragm captures changes in liquid pressure due to liquid level and converts it into storage level.

However, it must be used under condition that pressure inside the tank is atmospheric pressure.

■Features

- Easy to install even in places with limited installation space.

■Disadvantages

- If there are many foams in liquid, pressure will be uneven and accuracy will deteriorate.

- Accuracy will deteriorate if there is a lot of adhesion or sedimentation of solid matter.

- If a lot of air foams are generated, liquid pressure will be uneven and measured value will be incorrect.

- As liquid pressure changes depending on specific gravity of liquid, adjustment is required.

- When performing maintenance, tank must be emptied.

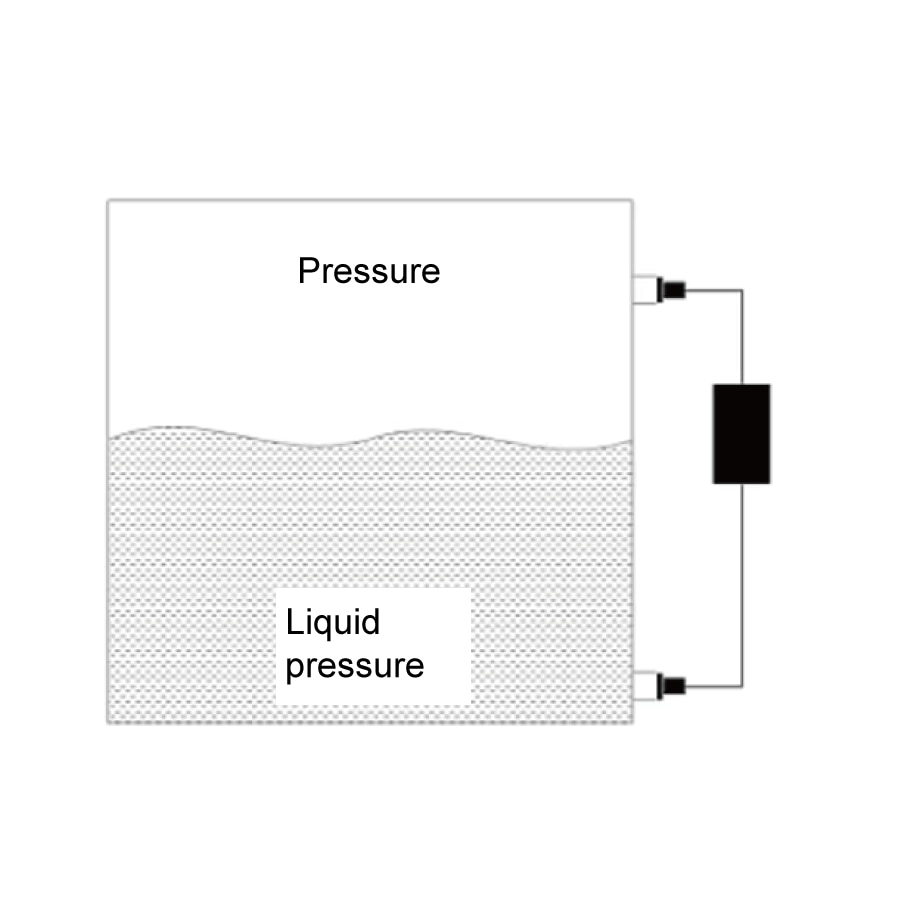

11. Differential Pressure Level Transmitter

■Principle

It consists of two parts: a diaphragm that measures liquid pressure and a diaphragm that measures tank internal pressure. Calculate storage level by subtracting tank internal pressure from liquid pressure.

■Features

- Measurement is possible without being affected by pressure changes inside tank.

■Disadvantages

: If there are many foams in liquid, pressure will be uneven and accuracy will deteriorate.

・Accuracy will deteriorate if there is a lot of adhesion or sedimentation of solid matter.

・If a lot of air foams are generated, the liquid pressure will be uneven and measured value will be incorrect.

・As liquid pressure changes depending on specific gravity of liquid, adjustment is required.

・When performing maintenance, tank must be emptied.

It consists of two parts: a diaphragm that measures liquid pressure and a diaphragm that measures tank internal pressure. Calculate storage level by subtracting tank internal pressure from liquid pressure.

■Features

- Measurement is possible without being affected by pressure changes inside tank.

■Disadvantages

: If there are many foams in liquid, pressure will be uneven and accuracy will deteriorate.

・Accuracy will deteriorate if there is a lot of adhesion or sedimentation of solid matter.

・If a lot of air foams are generated, the liquid pressure will be uneven and measured value will be incorrect.

・As liquid pressure changes depending on specific gravity of liquid, adjustment is required.

・When performing maintenance, tank must be emptied.

Reference Products

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

Please feel free to contact us if you have any inquiries.

Click here to download documents.

© Matsushima Measure Tech Co., Ltd.