Fluid Bed Processor Raw Material Loss Reduction in pharmaceutical industry

What is a fluid bed processor?

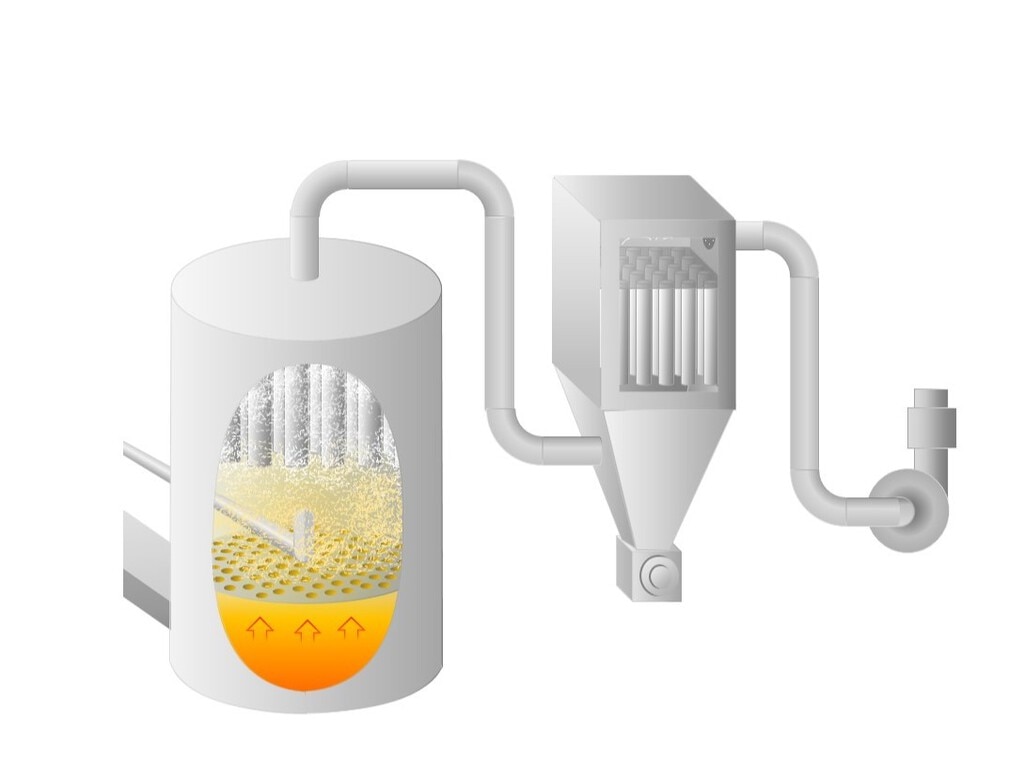

A fluid bed processor consists of several key components that work together to enable efficient drying, granulation, and coating processes:

- Bed chamber: The main vertical vessel where fluidization occurs, typically with a perforated bottom plate for air distribution

- Air handling unit: Includes filters, dehumidification, heating system, and temperature/humidity sensors to condition the inlet air

- Spray system: Nozzles for liquid addition during granulation or coating, with options for top, bottom, or tangential spray configurations

- Filter system: Captures fine particles from the exhaust air, often using a dynamic filter for continuous cleaning

- Product container: Holds the material being processed, designed for easy charging/discharging and cleaning

- Control system: Monitors and adjusts process parameters like airflow, temperature, and spray rate

The modular design of modern fluid bed processors allows for flexibility in configuration and scale-up from lab to production sizes. Construction materials are typically stainless steel to meet pharmaceutical GMP requirements.

Bag Filter Efficiency Analysis

Bag filter (Filter system of Fluid Bed Processor) efficiency is crucial for minimizing material loss and maintaining product quality in fluid bed processing. Key factors affecting filter performance include:

- Filter material selection - polyester, polypropylene, and PTFE offer different levels of particle retention and airflow

- Pore size - smaller pores increase particle capture but may reduce airflow

- Filter area - larger surface area improves efficiency and extends cleaning intervals

- Cleaning mechanism - pulse-jet, reverse air, or shaker systems impact filter cake removal

Regular analysis of pressure drop across filters, visual inspections, and particle size distribution testing of captured material can help optimize filter efficiency and detect early signs of degradation12. Implementing a preventive maintenance schedule based on operating hours or batch cycles is recommended to proactively replace filters before failures occur.

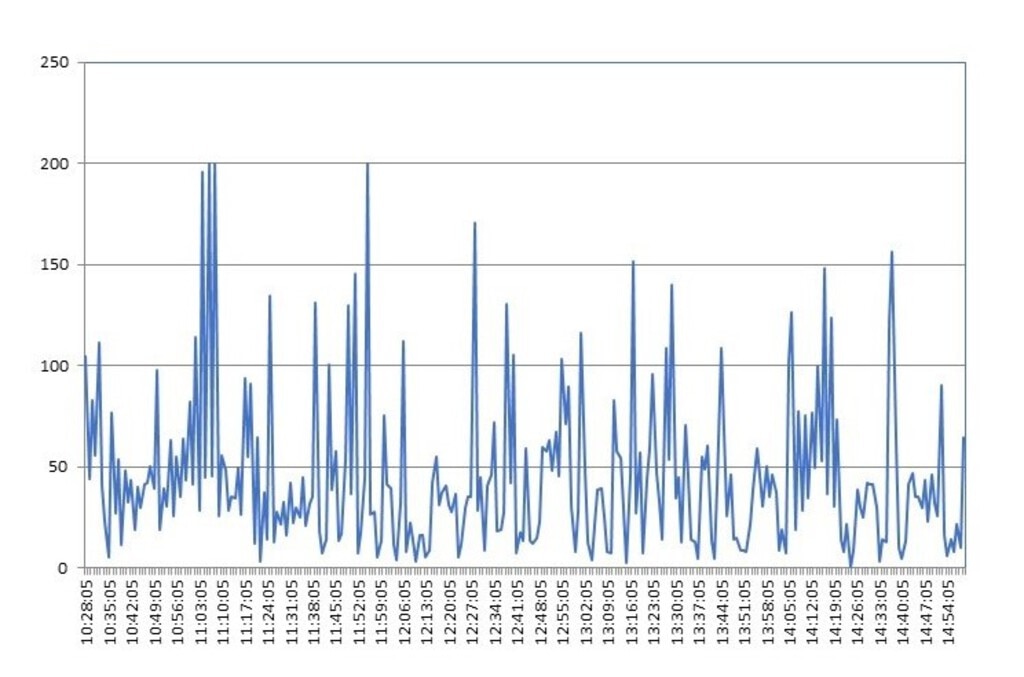

Real-time Dust Monitoring

Real-time dust monitoring systems provide continuous feedback on particle concentrations in the exhaust air of fluid bed processors, enabling rapid detection of filter failures and material loss. These systems typically utilize laser-based optical sensors to measure scattered light from airborne particles. Key benefits of real-time dust monitoring include:

- Immediate alerts when dust levels exceed preset thresholds, allowing quick intervention

- Trend analysis to identify gradual filter degradation before catastrophic failure occurs

- Integration with process control systems for automated responses like reducing airflow or stopping the process

- Quantification of material loss to assess economic impact and process efficiency

Modern dust monitors can detect particles as small as 0.1 microns and operate reliably in the high temperature and humidity conditions of fluid bed exhaust streams. Implementing real-time monitoring alongside traditional pressure differential measurements provides a comprehensive approach to filter integrity assurance and material loss prevention in pharmaceutical fluid bed processing operations.

Dust Monitor Integration

Dust monitors can be seamlessly integrated into fluid bed processor systems to provide real-time detection of filter failures and material loss. Key aspects of dust monitor integration include:

- Placement on the exhaust pipe to detect particles escaping through damaged filters

- Connection to the control system for automated alarms and process adjustments

- Ability to detect even small increases in particle concentration indicative of filter breaches

- Compatibility with high-temperature environments typical in fluid bed drying operations

By incorporating dust monitoring, manufacturers can quickly identify and address filter issues before significant product loss occurs, improving overall process efficiency and yield

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.