Dust Monitoring Equipment

What is a dust monitor?

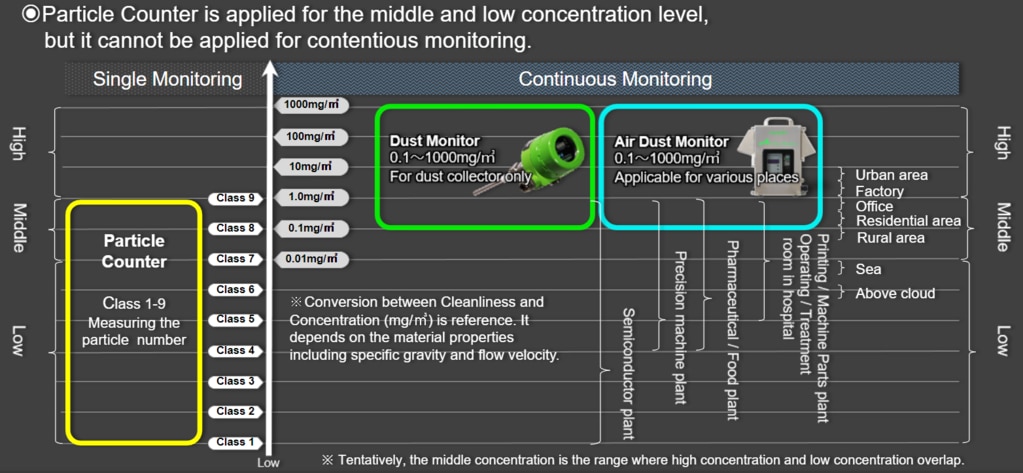

A Particle counter is one of the kind but it measures number of physical microparticles (pcs/m3) instead of concentration (mg/m3).

1. Working principle of dust monitors

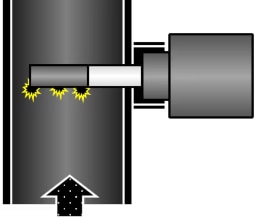

A. Triboelectric Dust Monitor

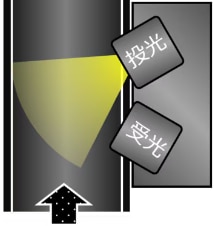

B. Light Scattering Dust Monitor

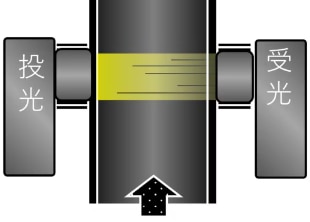

C. Light Transmission Dust Monitor

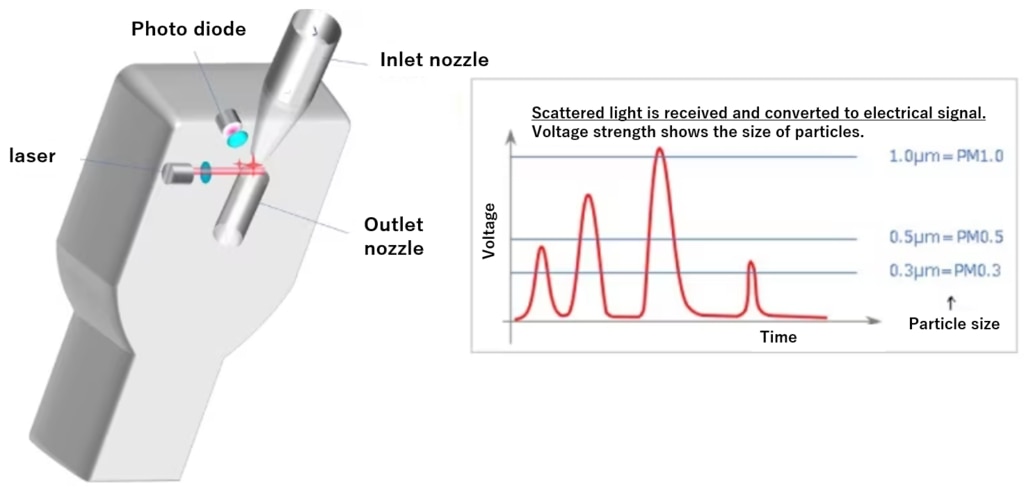

2. Working principle of particle counter

It sucks ambient air from the inlet nozzle and emits laser light to the area.

Then, emitted light scatters when it interacts with particles.

A photodiode in the particle counter detects the scattered light and converts into an electrical signal.

Particle size is determined based on the strength of the voltage signal and number of particles is calculated by number of waveforms.

3. Difference between particle counters and dust monitors

Particle counters measure "number of particles in the air (pcs/m3)" and dust monitors measure "particle concentration in the air (mg/m3)".

In case of low dust concentration situation, it is better to use particle counters (pcs/m3) because it's resolution is high and dust concentration value (mg/m3) is too low to use dust monitors.

But on the other hand, particle counter value (pcs/m3) becomes too high and difficult to make judgement in case of high dust concentration.

In this case, it is better convenient to use dust monitors (mg/m3).

Easier way to make judgement whether particle counters or dust monitors should be used is whether the dust concentration to be measured is higher or lower than the concentration level of general office or suburban outdoor.

Dust monitors are better in case it's higher than it.

Particle counters are better if it's lower than it.

In addition, particle counters are single measurement method.

Dust monitors are continuous method generally equipped with analog signal (DC4-20mA) for the continuous measurement output and have a few types to suit for each application.

Please refer to the positioning map below for more details.

= Positioning Map =

Application comparison between particle counters and dust monitors

| Applications for particle counters | Applications for dust monitors |

| ① Clean room in semiconductor factories | ① Dust collector leakage monitoring |

| ② Clean room in precision equiment producers | ② Dust generating work place like tunnels, domolition work, factories, etc. |

| ③ Clean room in pharmaceutical, food processing and beverage producers | ③ Welding fume |

| ④ Hospital operating room, etc. | ④ Offices, commercial facilities, etc. |

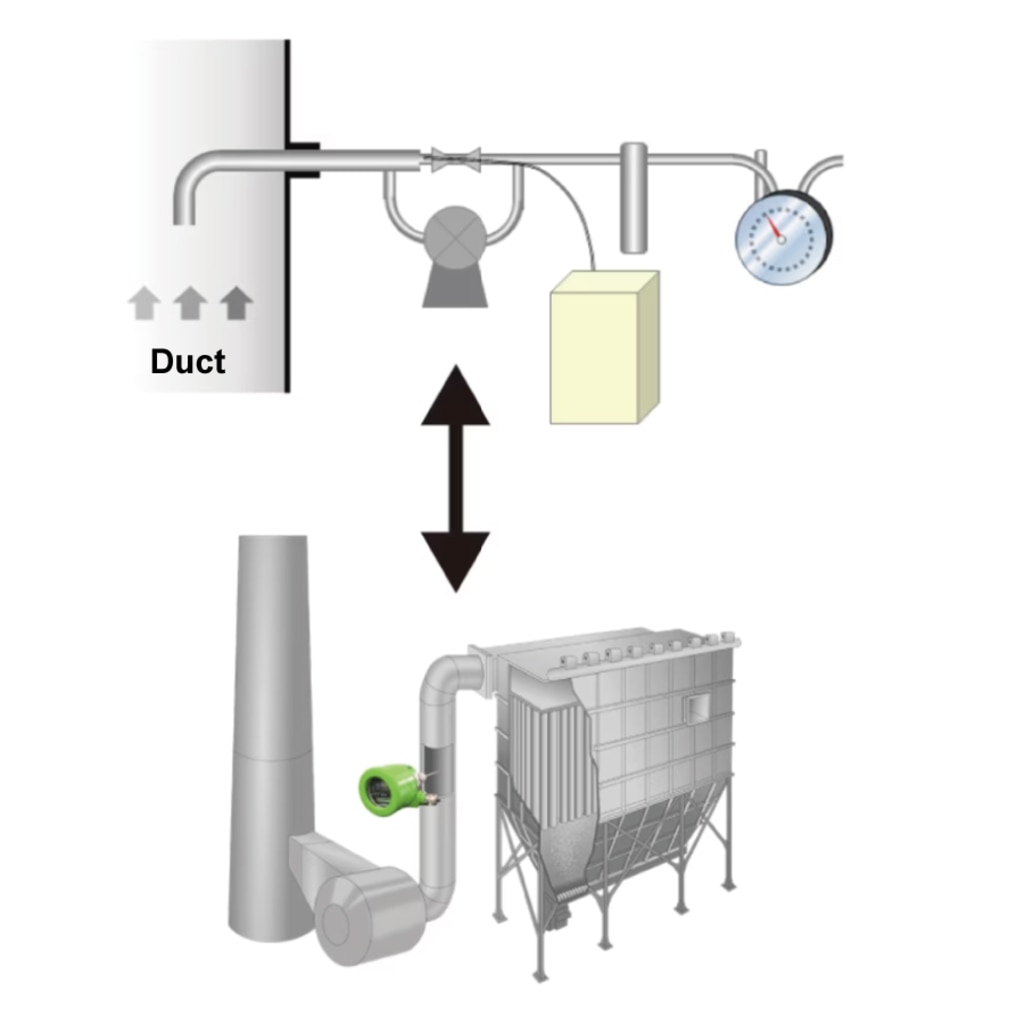

4. Triboelectric Dust Monitor

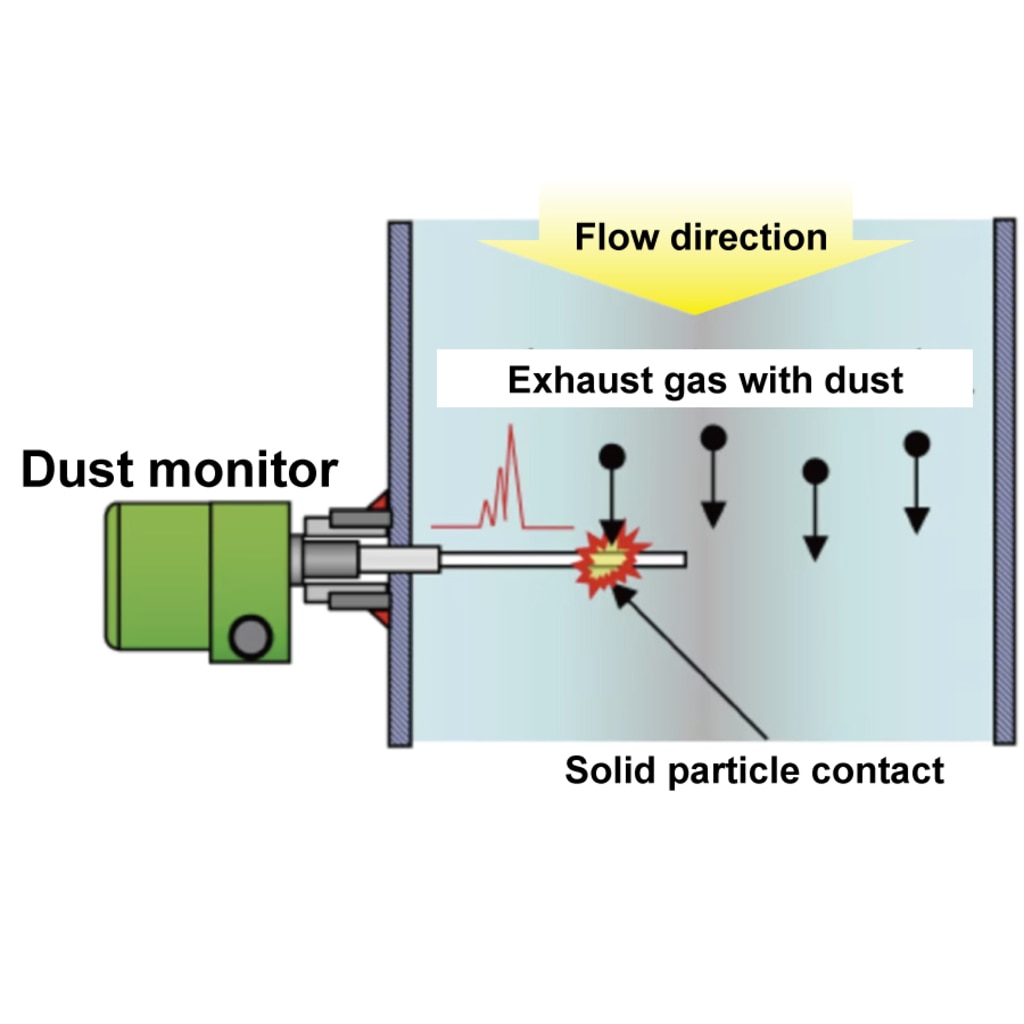

Operating principle of Triboelectric Dust Monitor

When the dust leaked into the exhaust gas contacts or passes near the probe of the Dust Monitor, charge transfer (tribo) occurs. The amount of charge transfer is detected as a relative concentration proportional to the dust concentration, and this is analog output and an alarm contact informs you of an abnormality.

Advantages of Triboelectric Dust Monitor

- 24-hour monitoring ensures that even the slightest leak is not overlooked. Achieve predictive maintenance .

- Eliminates sudden dust leaks, reducing the burden of periodic inspections. Contributes to labor saving .

- You can use up the filter to the end. This leads to a reduction in maintenance costs .

Features of Triboelectric Dust Monitor

Powder measuring instrument Dust Monitor adopts the triboelectric (electric charge) method. Its main features are:

Monitors 24 hours a day on behalf of people and does not miss even the slightest leaks.

Continuous measurement (0.1 to 1000mg/㎥) on behalf of humans.

We will notify you before the dust exceeds the regulation value. The filter can be used up to the end, realizing eco-conservation.

Dust meter conforming to JIS standards

An automatic dust concentration measuring instrument based on the performance evaluation method (JIS B7996). There is a strong correlation with the manual analysis method (JIS Z 8808) with a correlation coefficient of 0.969.

How to use?

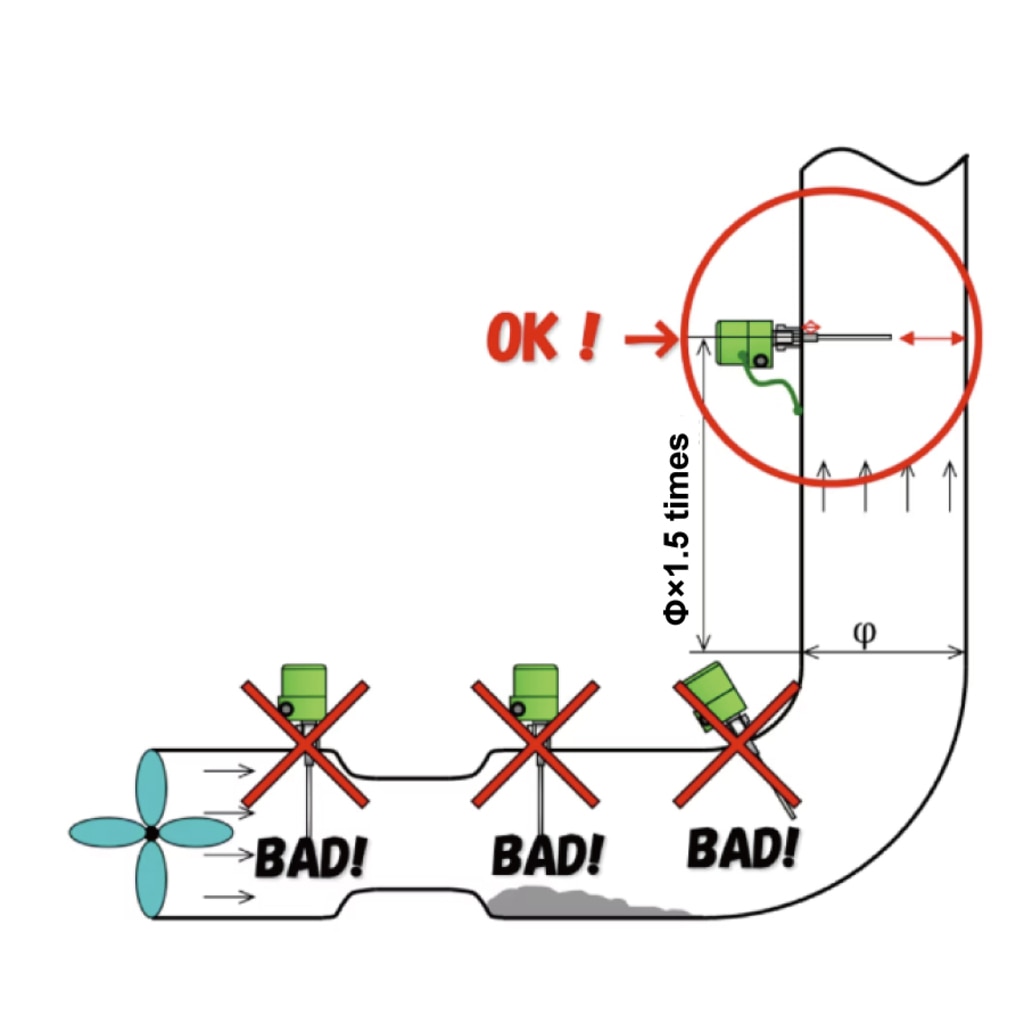

1.Determine mounting position

The flow velocity in the duct should be 4 m/sec or more, and please install it on a straight body that has a rectifying effect. Avoid bends, extreme narrowing, or near fans, as the airflow will be turbulent and the measurement will be unstable.

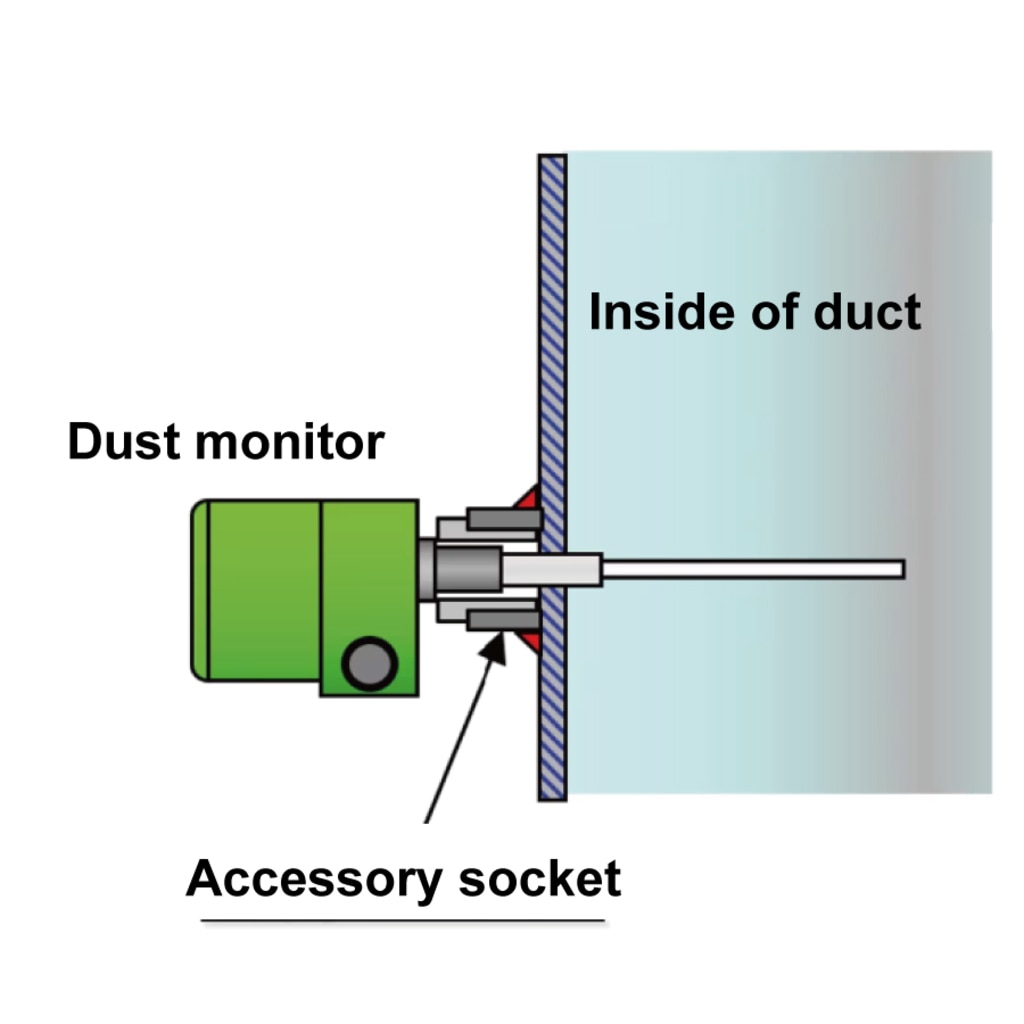

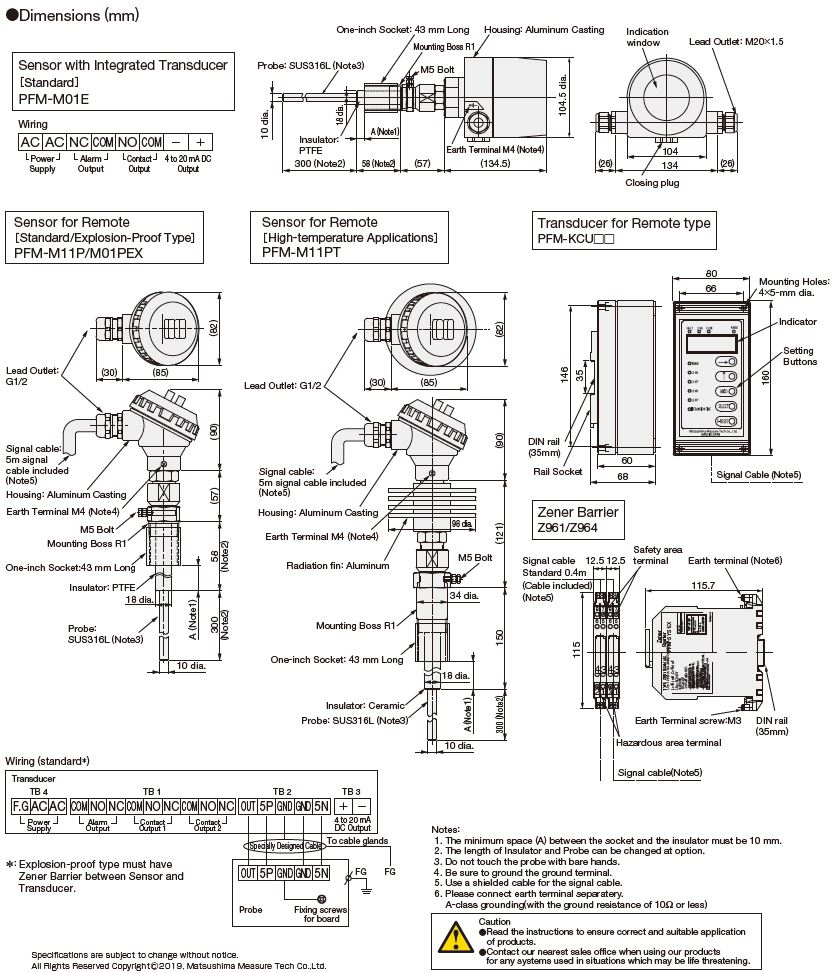

2. Mounting

Weld the included 1 inch socket into the perforated duct, insert the probe and screw it in. Be sure to connect the ground.

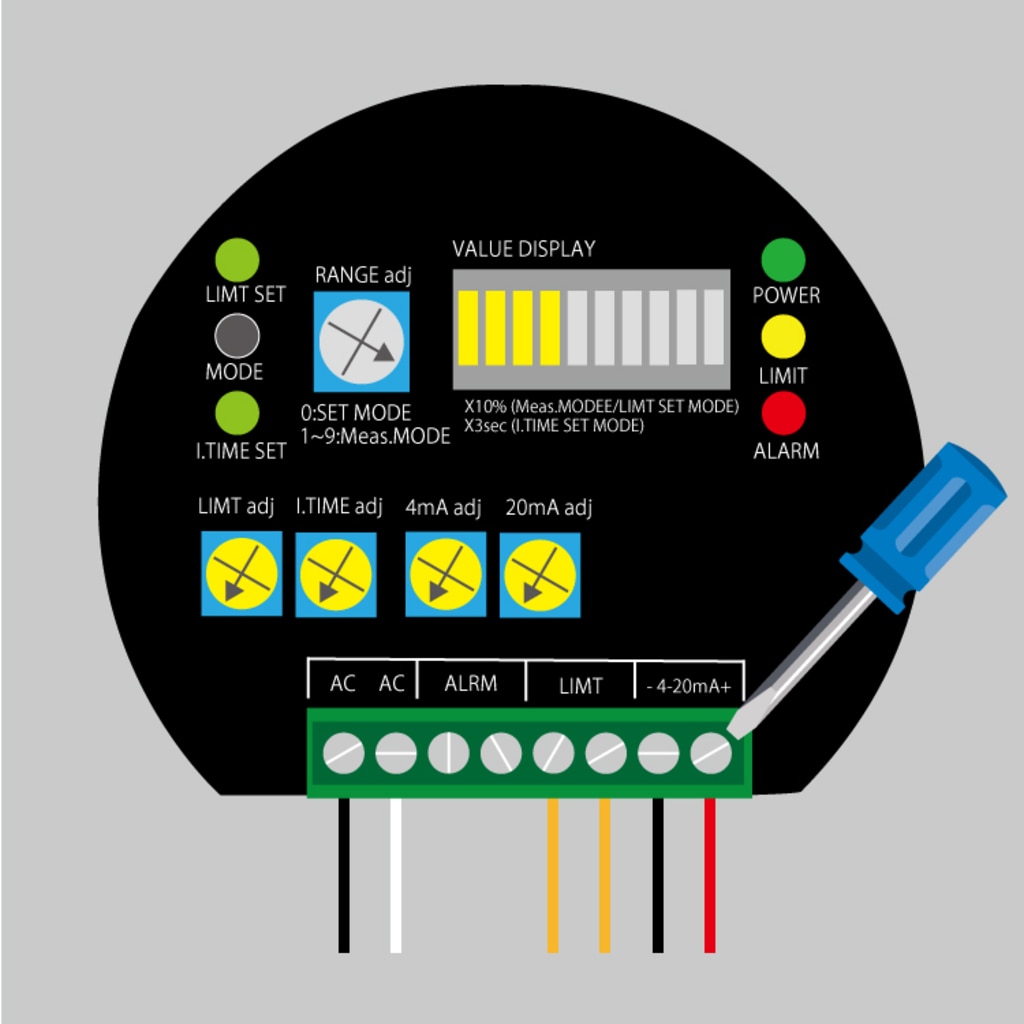

3. Wiring

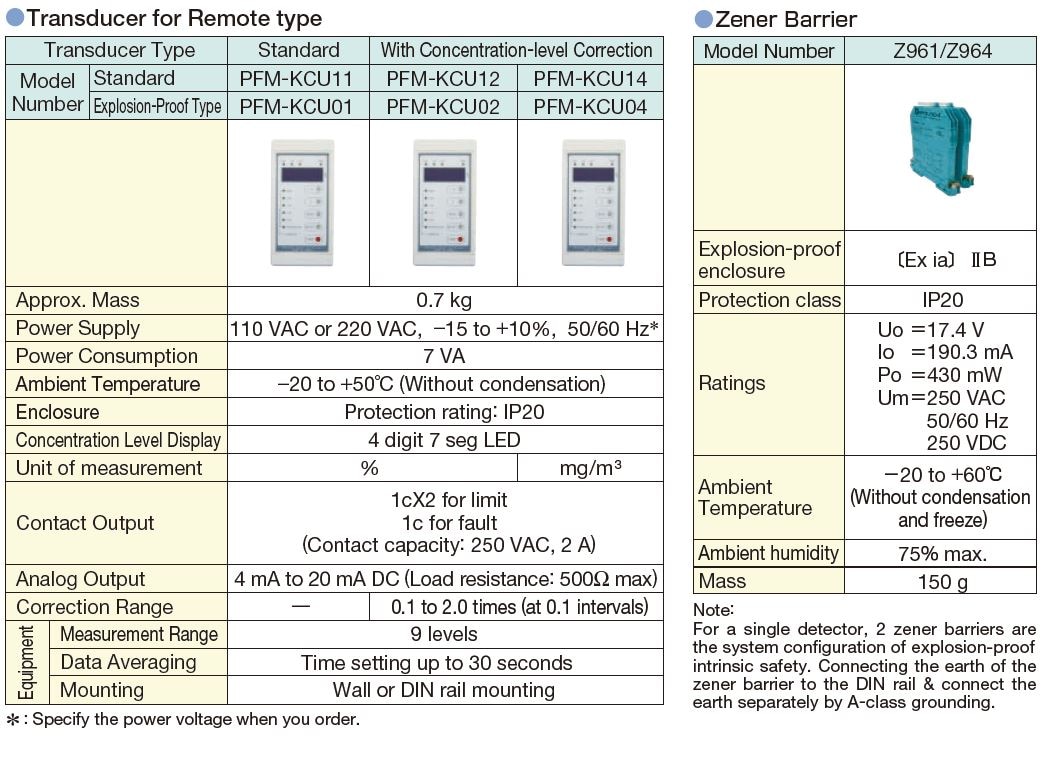

Wire to the power supply, analog output, and contact output. (The image is an integrated dust monitor.) Use a dedicated cable to connect the separate/high temperature/explosion proof sensor and the converter.

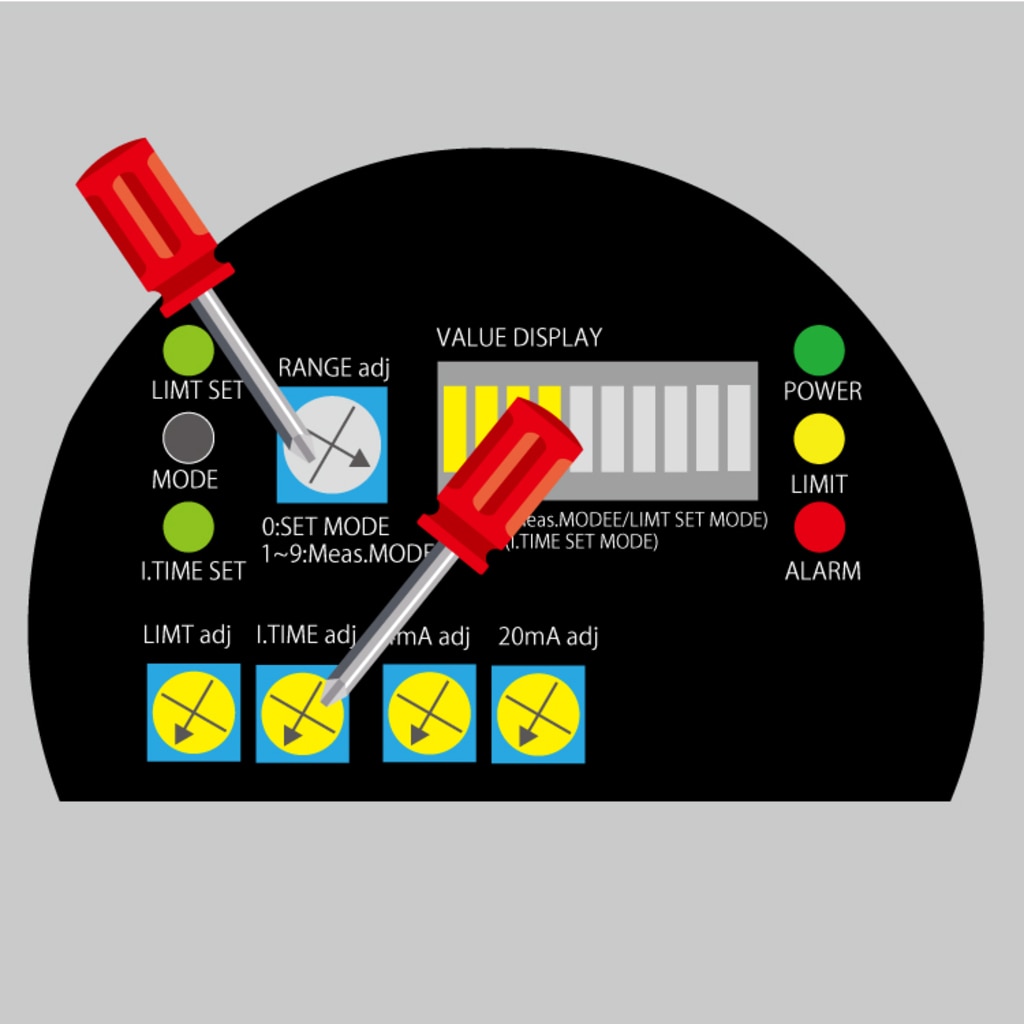

4. Adjustment

Carry out the adjustment when the flow velocity is constant and the filter is normal. Normally, set the range selector switch within the range of 1 to 9. Set the integration time as necessary.

*For details, please refer to the instruction manual.

Maintenance of Triboelectric Dust Monitor

If you use it for a long time, you may be concerned about the soundness of the Dust Monitor.

We offer a design that considers after installation and a service that considers long-term reliability.

To remove the sensor, just remove one bolt

When removing the sensor, the probe can be easily pulled out simply by loosening the bolt attached to the boss. It saves you the trouble of removing the cable.

POINT!

Assuming that the probe will be pulled out, wire the cable with a margin.

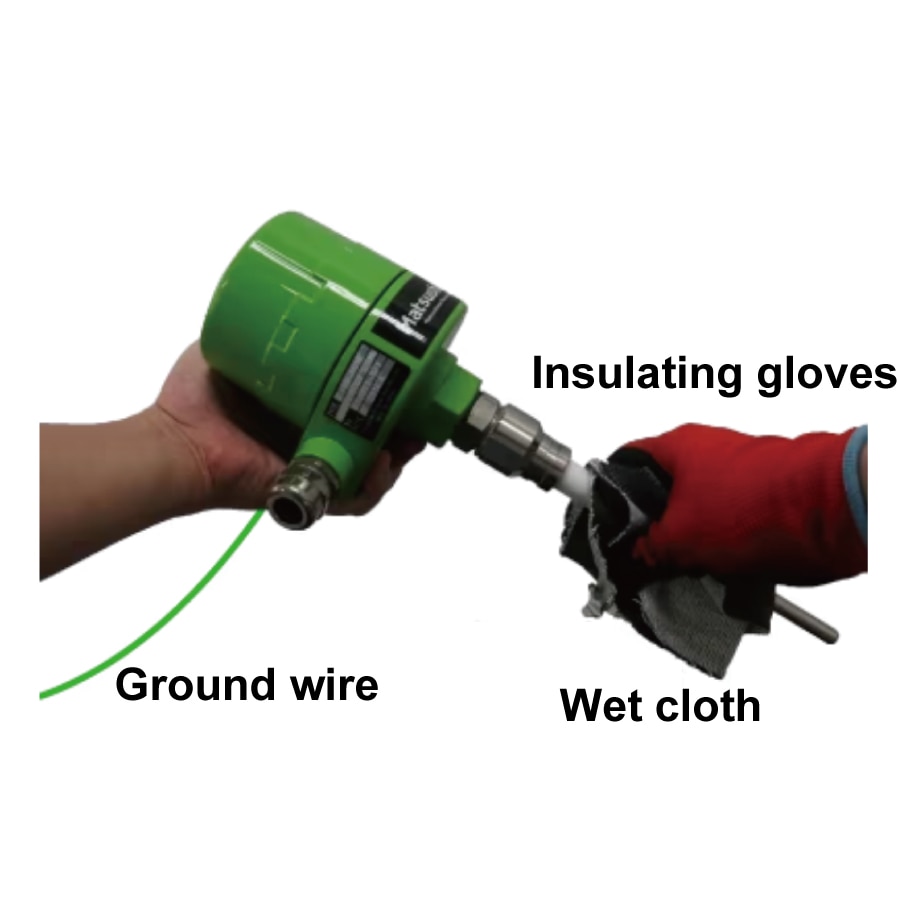

To clean, just wipe the probe with a waste cloth

For cleaning, simply wipe off dirt from the probe with a slightly damp cloth. If there is no dust leakage, it will not get dirty, so it is recommended to clean it when the equipment is stopped.

POINT!

If you clean the probe as it is, it will short circuit the board, so turn off the power, wear insulated gloves, and work with the ground connected.

If you are concerned about whether the device is normal, check with the soundness check service

If you are unsure if your Dust Monitor is working properly, please use our health check calibration and adjustment service.

POINT!

Our service personnel can visit the site or send the main unit to our factory for confirmation.

* Please check here for details .

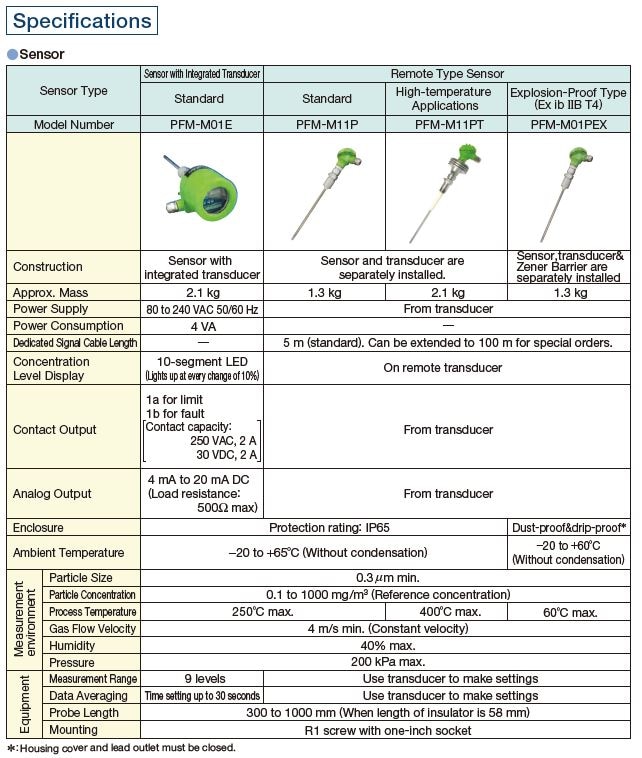

Model lineup of Triboelectric Dust Monitor

We offer four main lineups, assuming various usage scenarios for customers.

In addition, we will respond according to the site, such as specifying the probe length, flange mounting according to the equipment, and the length of the dedicated cable.

\ Download or Request for quote /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.