Blast Furnace Level Measurement Solutions

Level measurement in blast furnaces is a critical process that employs advanced technologies such as radar sensors and robust mechanical systems to monitor both the burden level at the top of the furnace and the molten metal level tapping into the torpedo car or iron ladle, ensuring stable and efficient blast furnace operation.

Matsushima Measure Tech Japan is one of the pioneer in this application since 1980's and have been providing both latest technologies and mature solutions.

Burden Level Detection Systems

Two main technologies are used to measure the burden level (stockline) in blast furnaces, which are radar and mechanical stockline indicators.

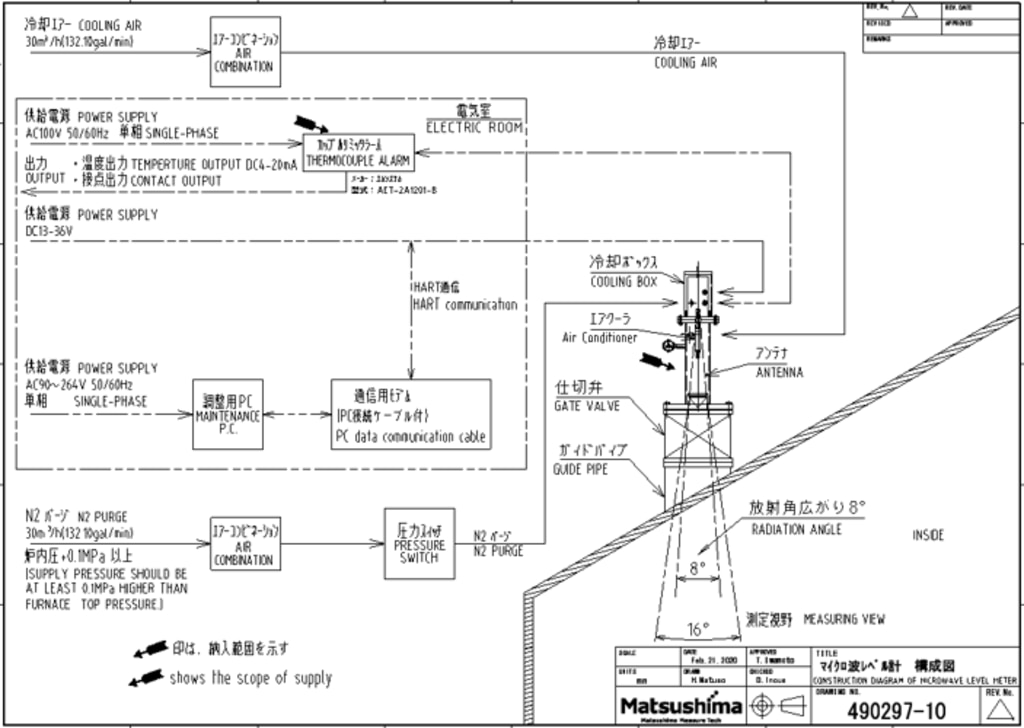

Radar level detection system features:

- Non-contact measurement with electromagnetic wave principle is unaffected by operating temperature or changing gas compositions.

- Almost maintenance free because there is no mechanical moving parts.

- Continuous measurement even during material charging.

- Detection of material slipping and hanging possible.

- Long measurement range up to the bottome of furnace.

- Cost effective (both initial cost and running cost) comparing to the mechanical system.

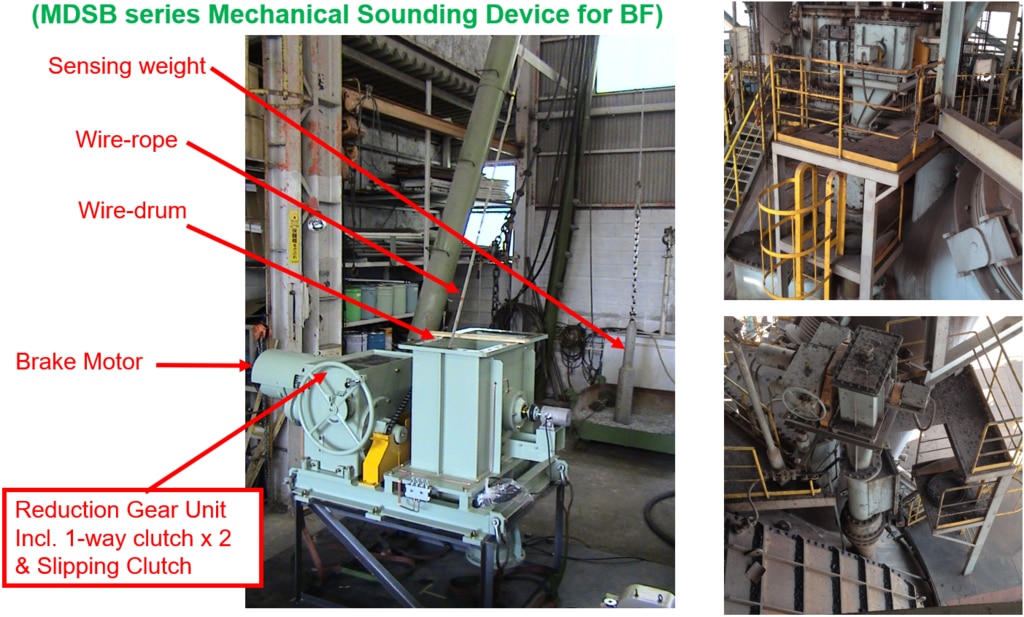

Mechanical stockline recorder system features:

- Using a cable drum in a gas-tight casing and measuring weights.

- Operates at an ascent speed of 60m/min and a descent speed of 42m/min.

- Powered by electric motor with VVVF drive and manual brake release lever.

- Matsushima Measure Tech is offering unique torque control system (slipping clutch mechanism) which provides headacheless adjustment and free from troubles by electrical noise.

- No complicated electrical torque management/parameters setting in case of the slipping clutch system.

Both systems are essential for controlling the burden distribution in the blast furnace and by monitoring the burden surface profile, contribute to more stable and efficient blast furnace operation.

Molten Metal Tapping Level Monitoring

Torpedo cars are horizontal cylindrical containers used to transport molten iron tapped from a blast furnace at high temperatures of over 1,400degC. Accurate level measurement is essential for the safe and efficient loading of this molten iron.

Torpedo Car Level Measurement System Features:

- FMCW Radar Level Transmitters are widely used since 50 years.

- It is installed on the casting floor and transmits microwaves through the antenna to the molten iron surface in the torpedo car. The reflected waves are then received to continuously measure the level.

- Accurate understanding of the filling status improves safety and enables efficient operation (productivity improvement) of torpedo cars.

- Also running cost saving and laborsaving expected.

Sensing Technologies of Matsushima Measure Tech

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.