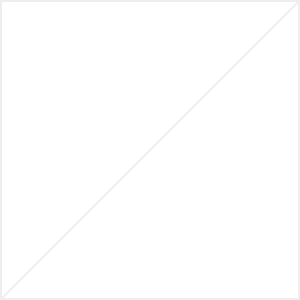

Level measurement solutions for vertical shafts and primary crushers in mines

Problems on level measurement at vertical shafts

Raw material (ore stone) is charged from trucks to vertical shafts.

This level should be maintained at an appropriate level so that the conveyor receiving material at the bottom of shat does not break by the impact.

Level sensor should be installed for this purpose but there are some prolems:

1. Contact type sensor easily breaks by vibration or hit of ore!

2. Level changes rapidly because the size of ore is big!

Problems on plugging detection at the crushers

The next process (primary cruhsers) crushes ore stone. This crusher process has a risk of overflow when bigger ore bites in the facility. Level sensor is useful to detect the plugging situation but there are some problems:

1. Faster followability is required because ore is big and level changes rapidly.

2. Contact type sensor may break because the ore is big and heavy.

Solves by Radar Level Transmitter!

① Level measurement for shafts

* Protection case is recommended to protect the sensor from the rebounding ore stone.

② Plugging detection for crushers

* Installation at the place, where prevent direct vibration from the site, is recommended.

1. Non contact measurement away from the charging area can prevent damage from the rebounding ore!

2. Fast followability allows immediate measurement (detection) even when 1m size ore is charged!

Useful Features

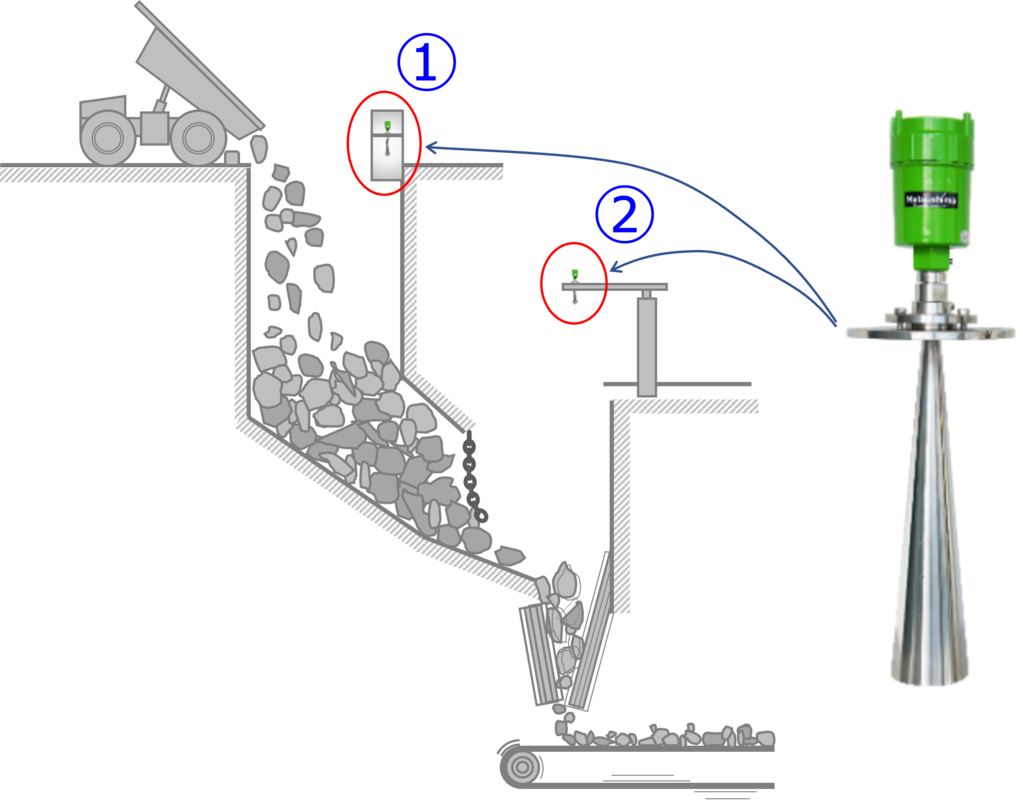

Feature 1) Fast Followability

26G Radar Level Transmitter (Ver.2.0) has a faster followability so that catches even 10m rapid level change in only 2 seconds.

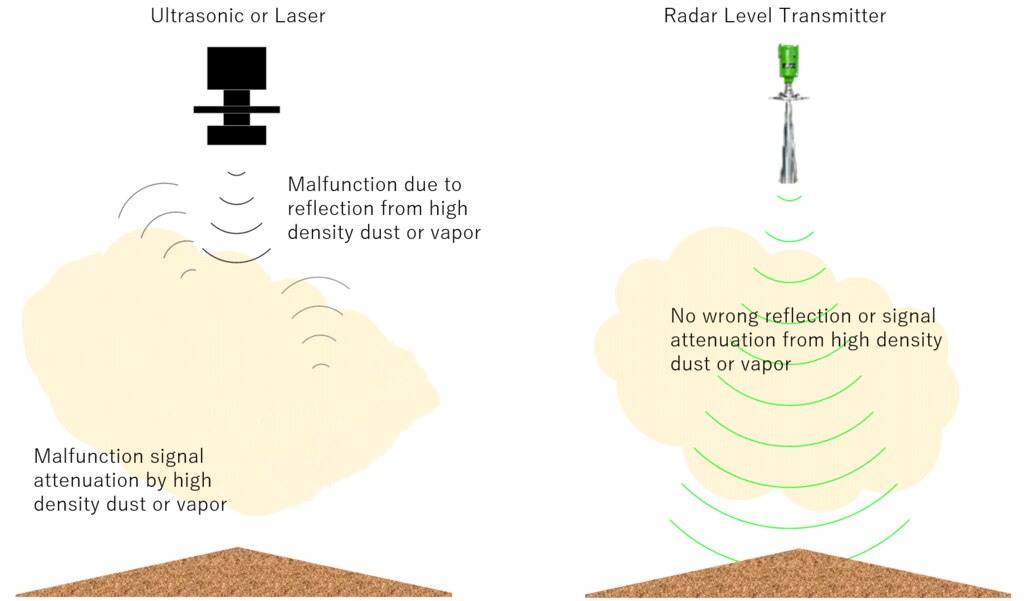

Feature 2) Permeability

Microwave has a useful characteristic that can go through flying dust or vapor, so it provides stable measurement under such conditions.

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.