Conveyor Belt Rip Accident Prevention

Problems at the site

Conveyor belt rip accident generally happens at transferring chutes area.

There are many transferring chutes required to transport raw materials from mining area or ship unloading facilities to next process on bulk material handling process, however, this transferring chute area has a risk of belt rip accident which happens when sharp stone or other foreign obstacles mixed in the transported raw material stack in the conveyor belt just underneath the transferring chute and tear the belt because the conveyor is stil running.

Belt Rip Detector is the solution to detect the accident and stop the conveyor to minimize the loss but there are some problems of detecting performance or maintenance work, etc.

Malfunction by site vibrations

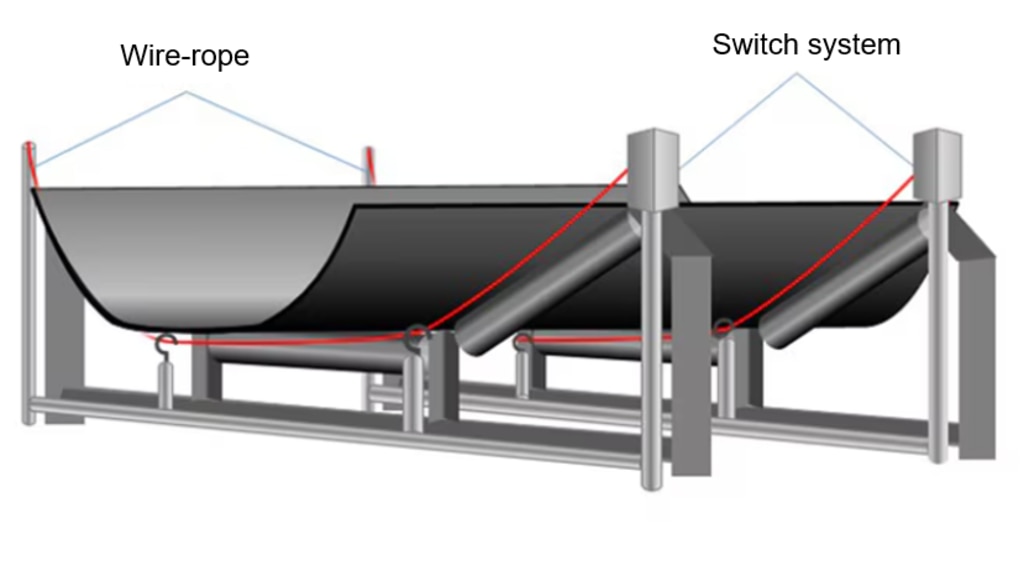

Wire-rope Switch Type Belt Rip Detector with mechanical switch construction may cause malfunctions frequently when the site vibration is big.

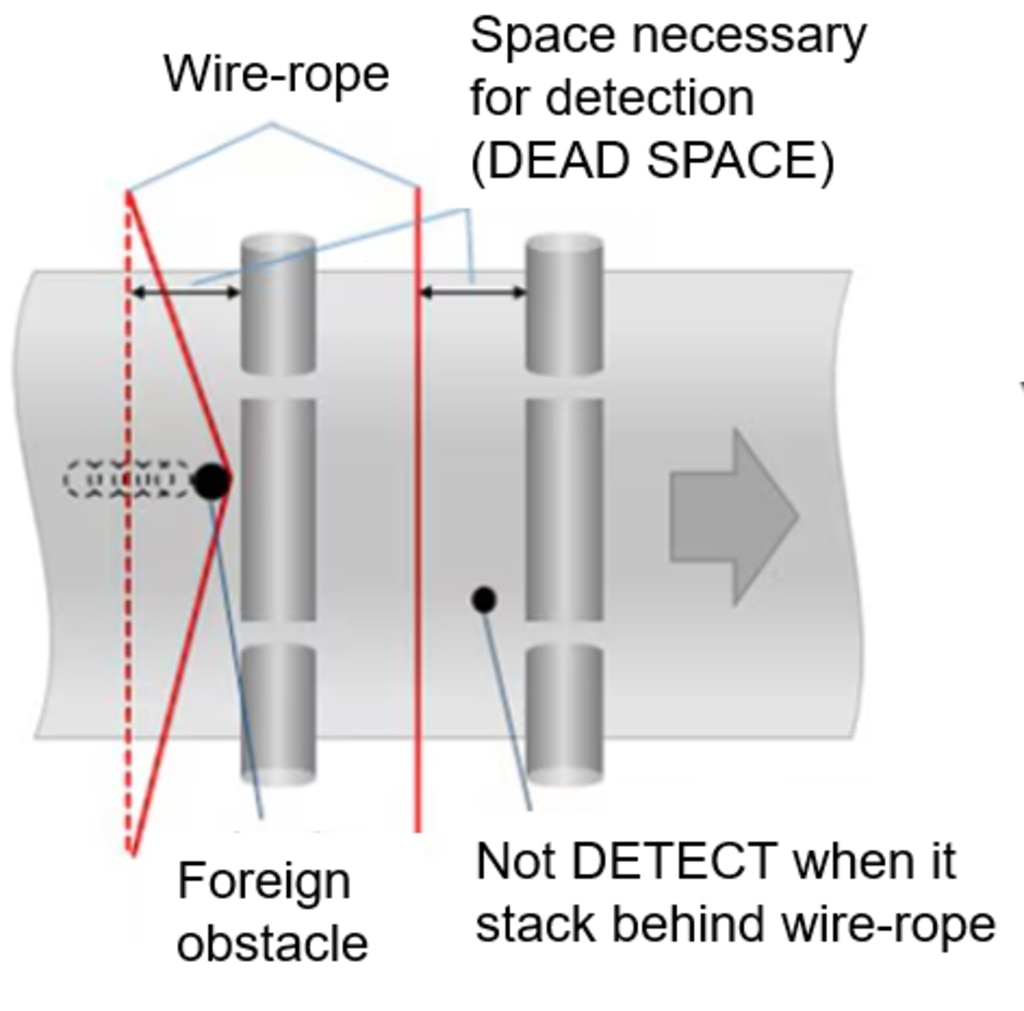

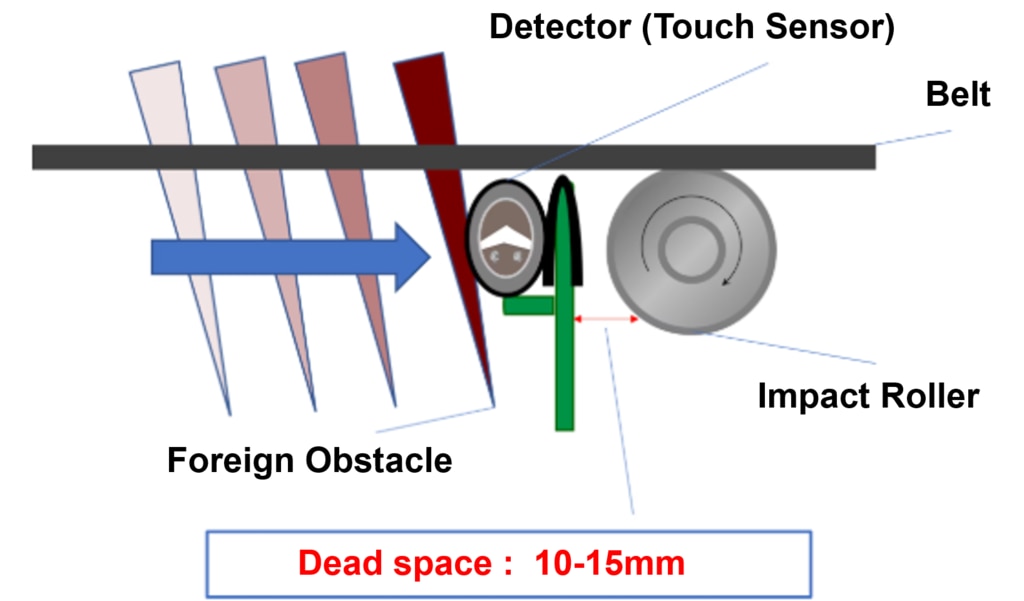

Undetectable Dead Space

Wire-rope type detector requires certain space for tripping switch and this space becomes DEAD SPACE for detection.

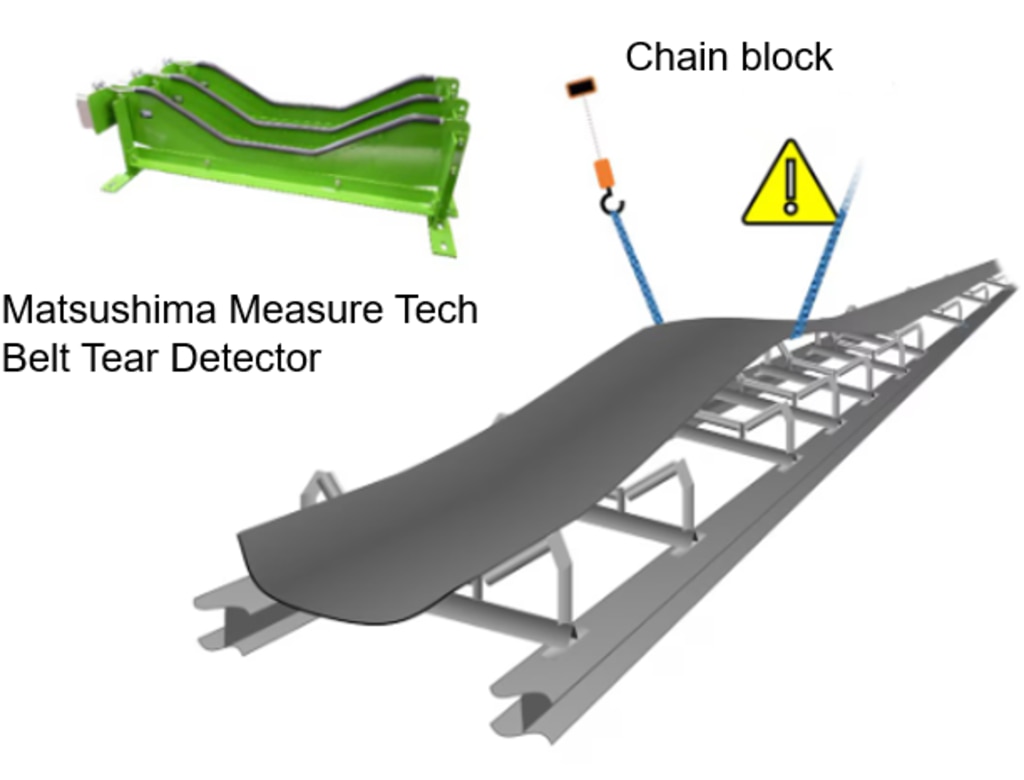

Heavy installation work

Conveyor belt must be suspended by chain block to install the detectors and those work sometimes requires unexpected time and manpower.

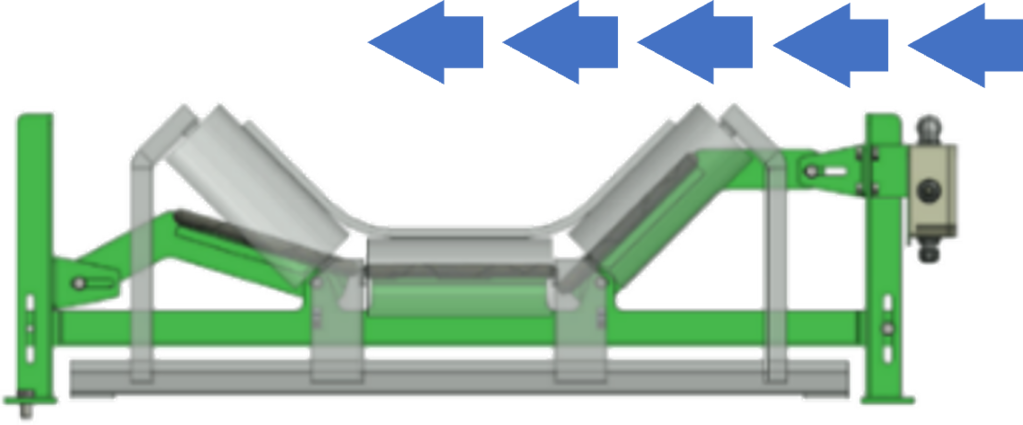

Trough Angle Adjustable Belt Tear Detector solves them!

Matsushima Measure Tech Belt Tear Detector, which sensor system is touch sensor principle instead of wire-rope system and has trough angle adjustment mechanism, provides stable detection without dead space and easy & flexible installation.

Stable under vibration

Detection without space

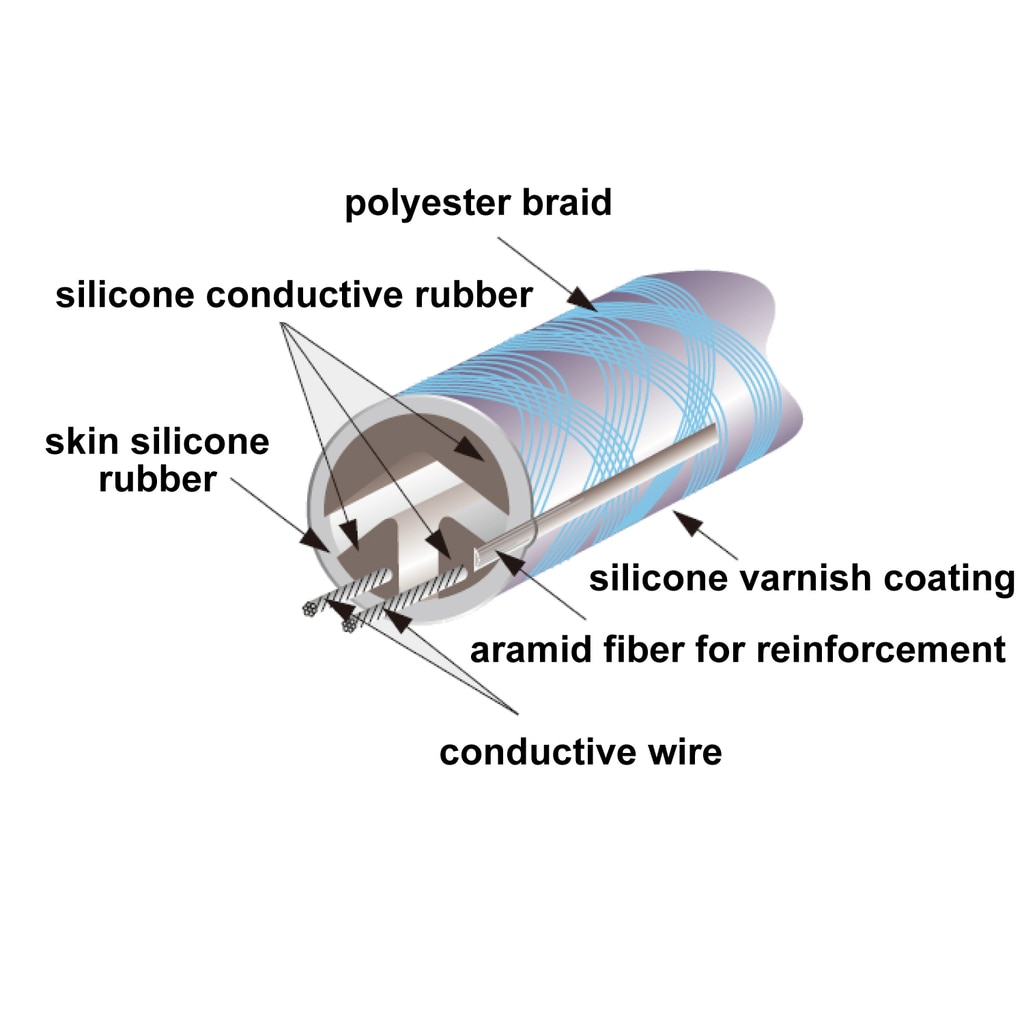

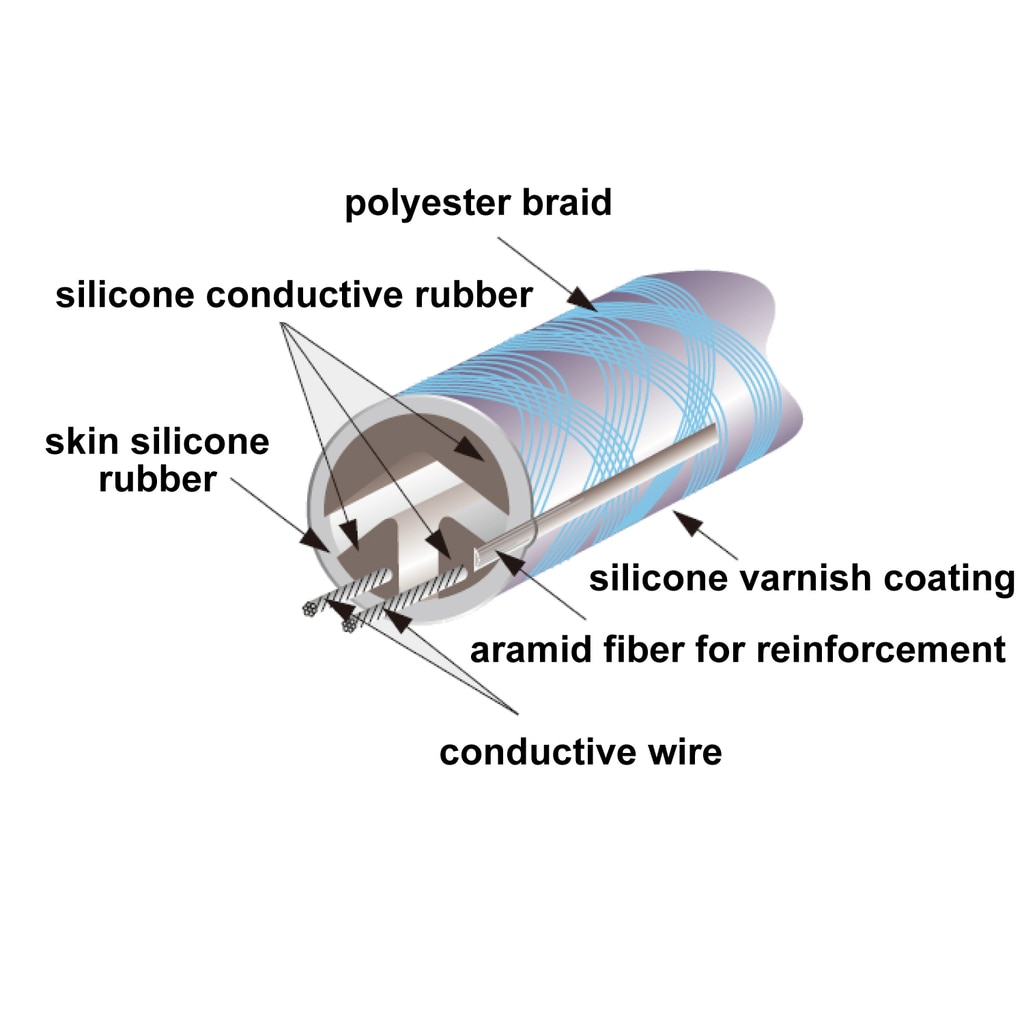

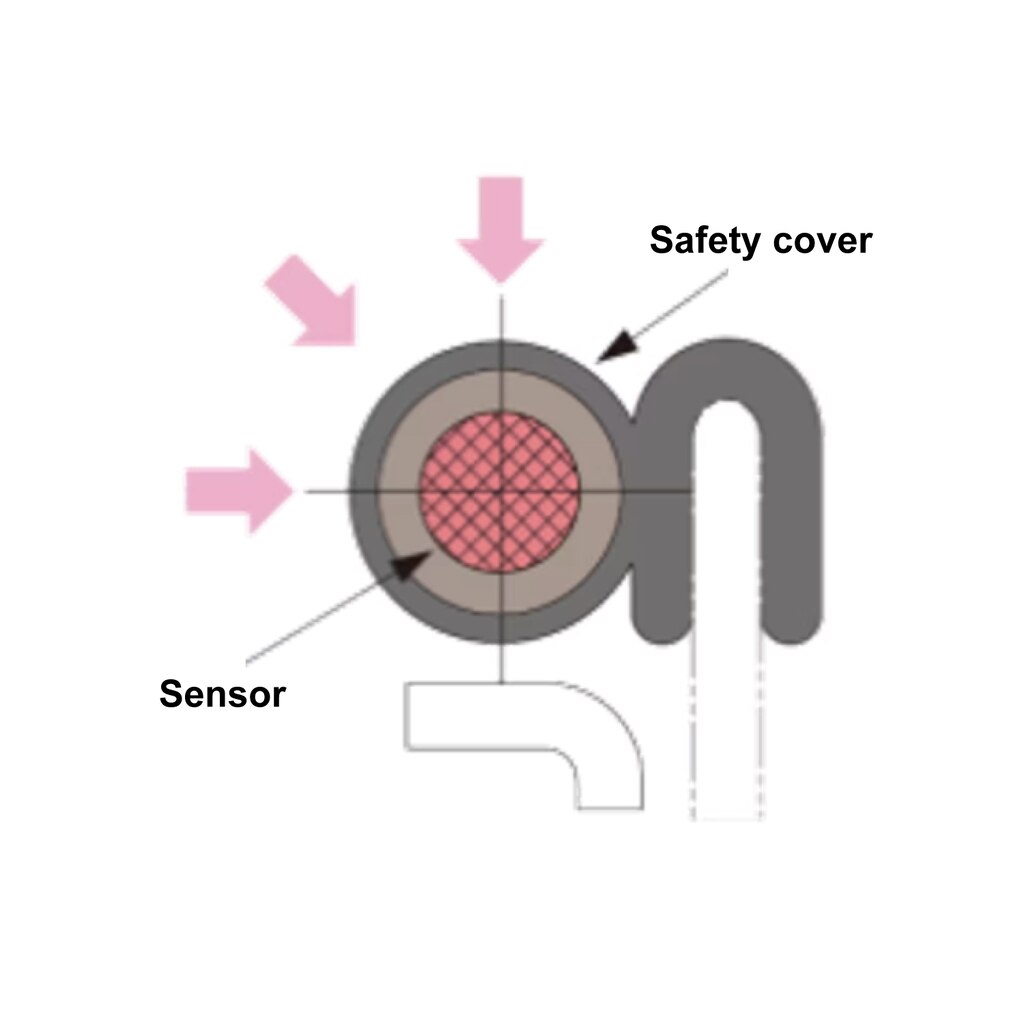

It is touch sensor (cable switch) system which detects when it is pressed by the foreign obstacle.

So, the dead space is quite narrow because the necessary space for detection is small.

Easy & Flexible installation

Trough angle adjustment mechanism allows easy installation without suspending the conveyor belt by chain block.

Installation work time including preparation will be reduced into half or less.

Featured Functions

Immediate detection for the rip accident

Detection sensitivity maintained

The touch sensor is protected by safety cover and has no bad influence from dust accumulation or environmental conditions such as ultraviolet rays, sea breeze, etc.

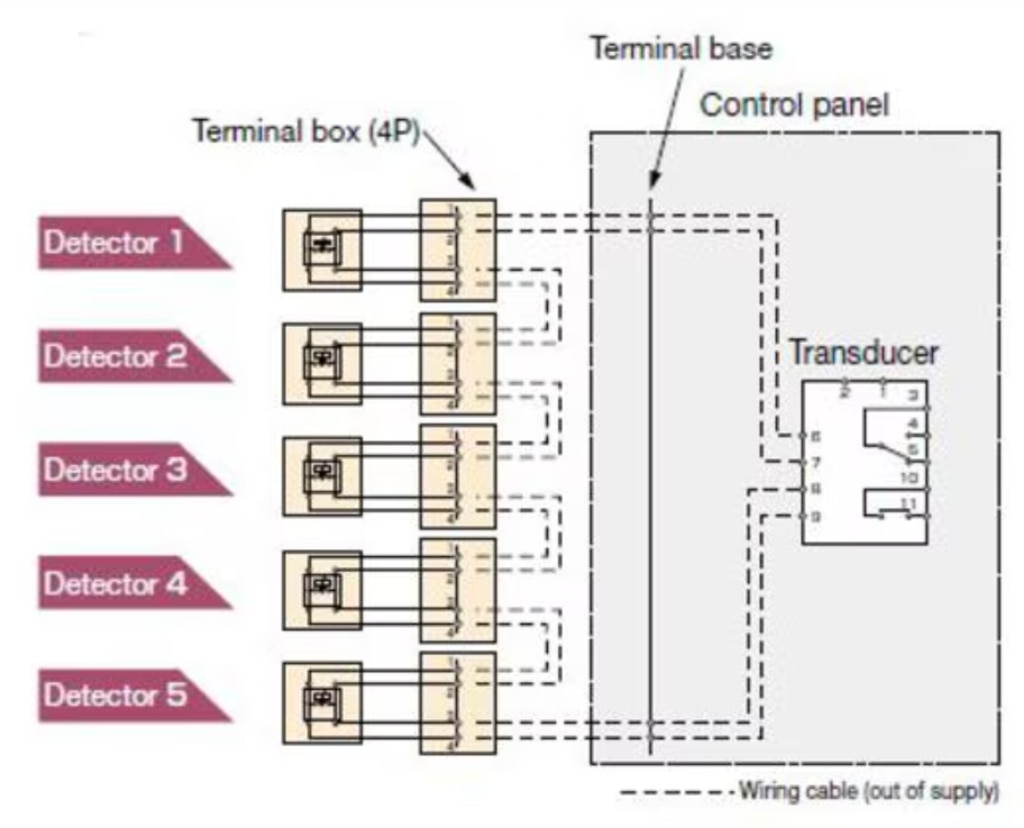

Multiple sensors configuration

One transducer can be connected to five detectors and therefore possible to set to multiple impact rollers at the transferring chute area.

Benefits

Safe Operation

Stable detection dispels worries of trouble.

Time saving

Detector mounting work time and maintenance time will be reduced.

Cost reduction

Possible to minimize the loss of accident besides unwanted work will be reduced.

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.