Belt Conveyor Protection Equipment

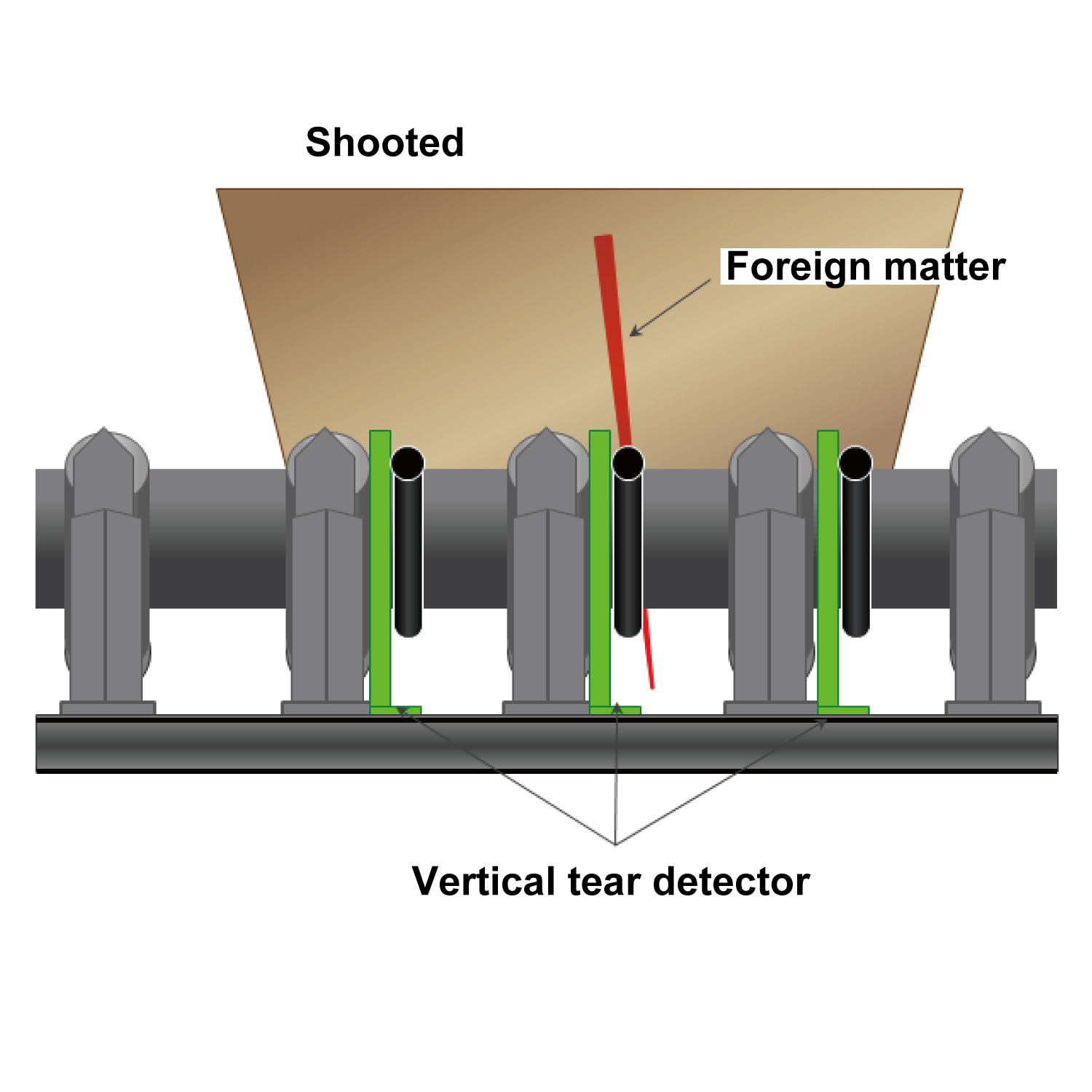

Mechanism of Conveyor Belt Rip Accident

The mechanism of conveyor belt tear accidents is mainly caused by the following factors:

- Foreign object ingress: Sharp objects or large impurities can get caught in the conveyed material and penetrate the belt, causing tears.

- Structural Defects: Poor design or construction of the conveyor system can put undue stress on the belt, leading to tears.

- Impact damage: A heavy object falling on the belt or a high-speed collision can cause scratches or holes in the belt surface, which can then develop into tears.

These factors, acting alone or in combination, can cause longitudinal or transverse tears in the belt. Once a tear occurs, it can grow rapidly and lead to the complete rupture of the belt.

Early detection and appropriate preventive measures are the key to preventing serious accidents.

How to prevent the conveyor belt rip accidents and minimize the loss of the accident.

Therefore, it is also important to consider an appropriate detection system of the accident to minimize the loss when it occurs.

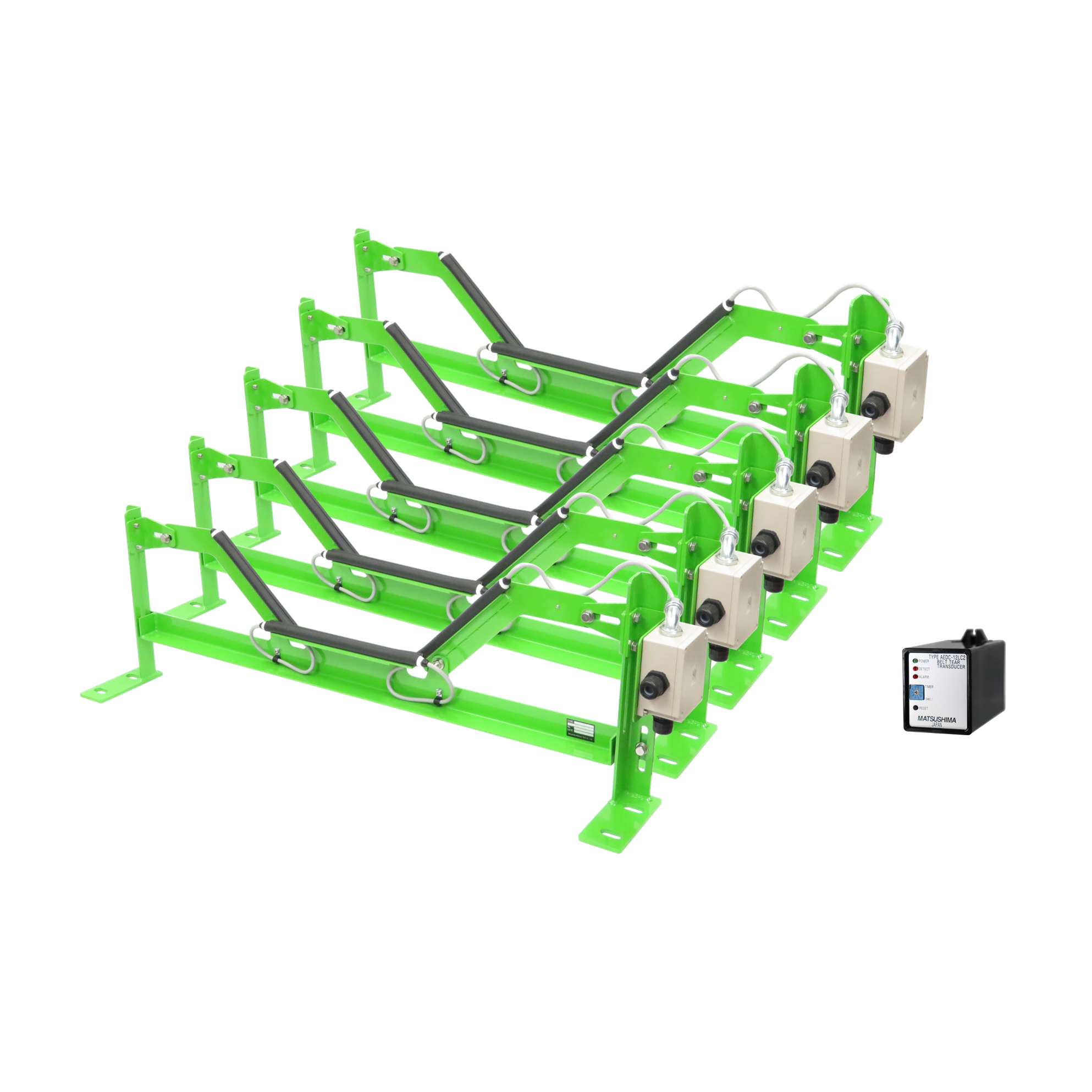

Touch sensor type Belt Tear Detector is one of the most reliable solution.

Please refer to the following for details.

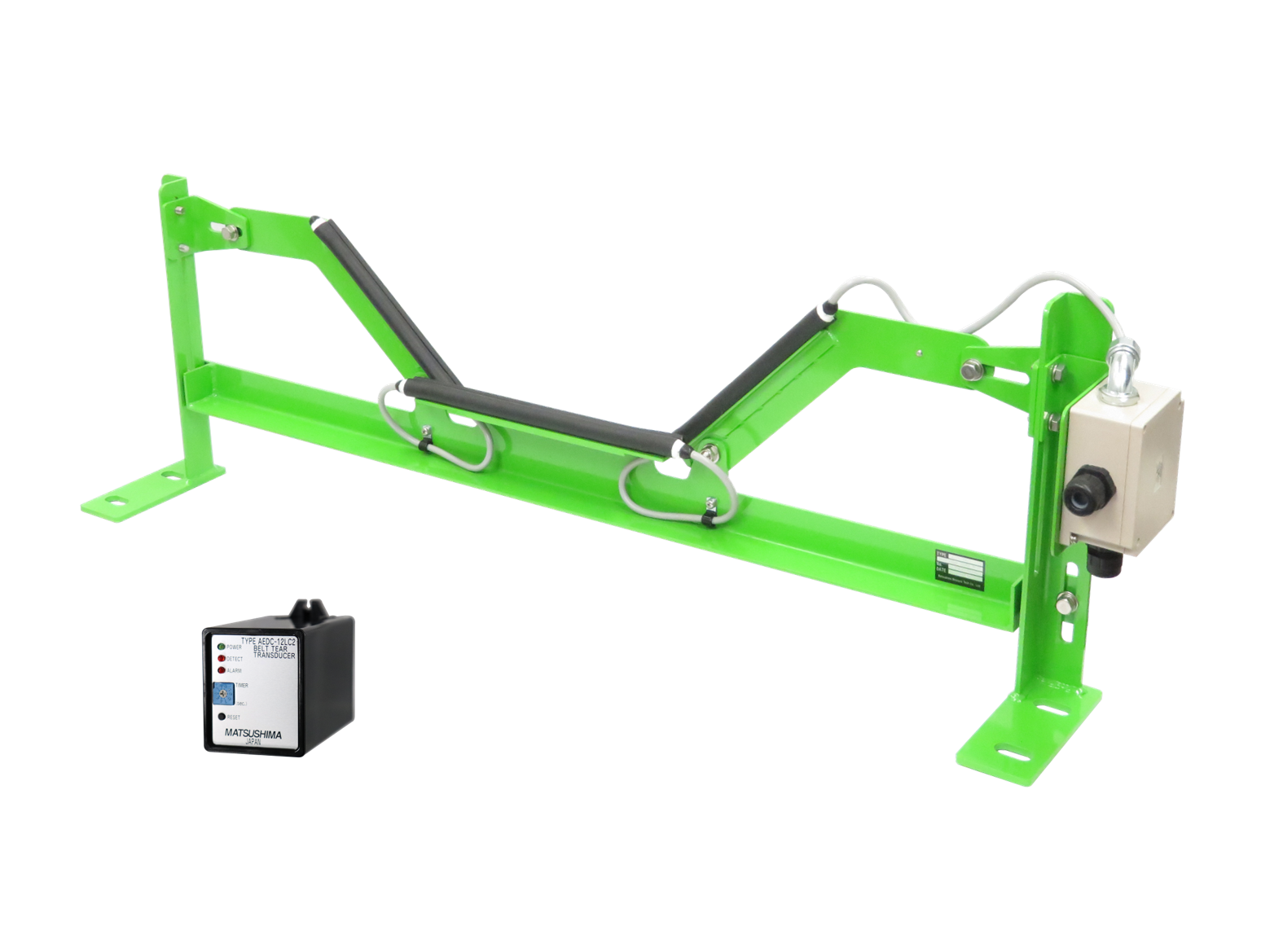

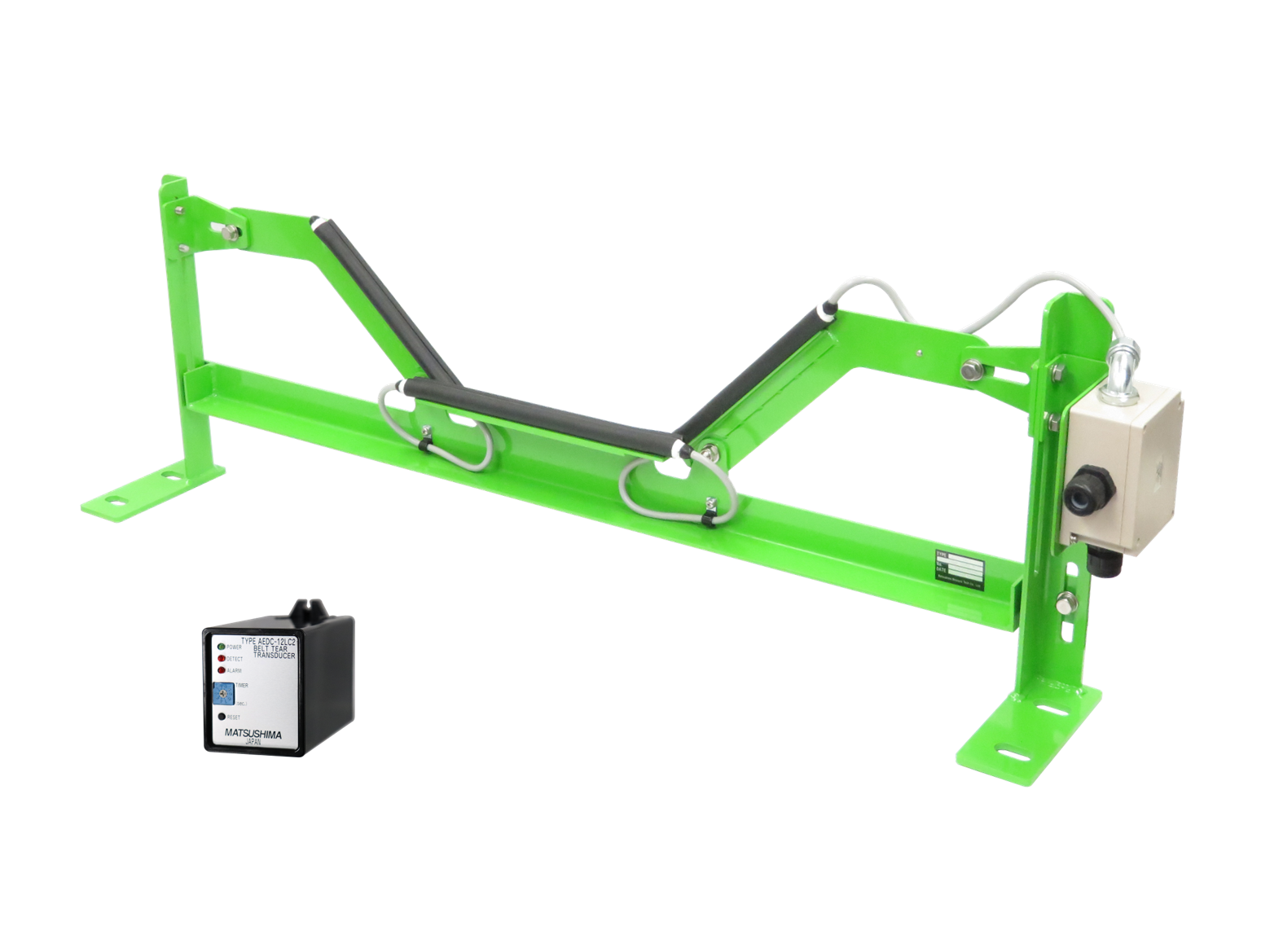

Touch Sensor Type Belt Tear Detector

Advantages

- By detecting belt damage at an early stage and stopping equipment, huge repair costs can be reduced.

- Damage to conveyor belts and equipment can be minimized.

- Production losses can be kept to minimum because recovery work is short.

\ Download or Request for quote /

Features of Belt Tear Detector

Can be used

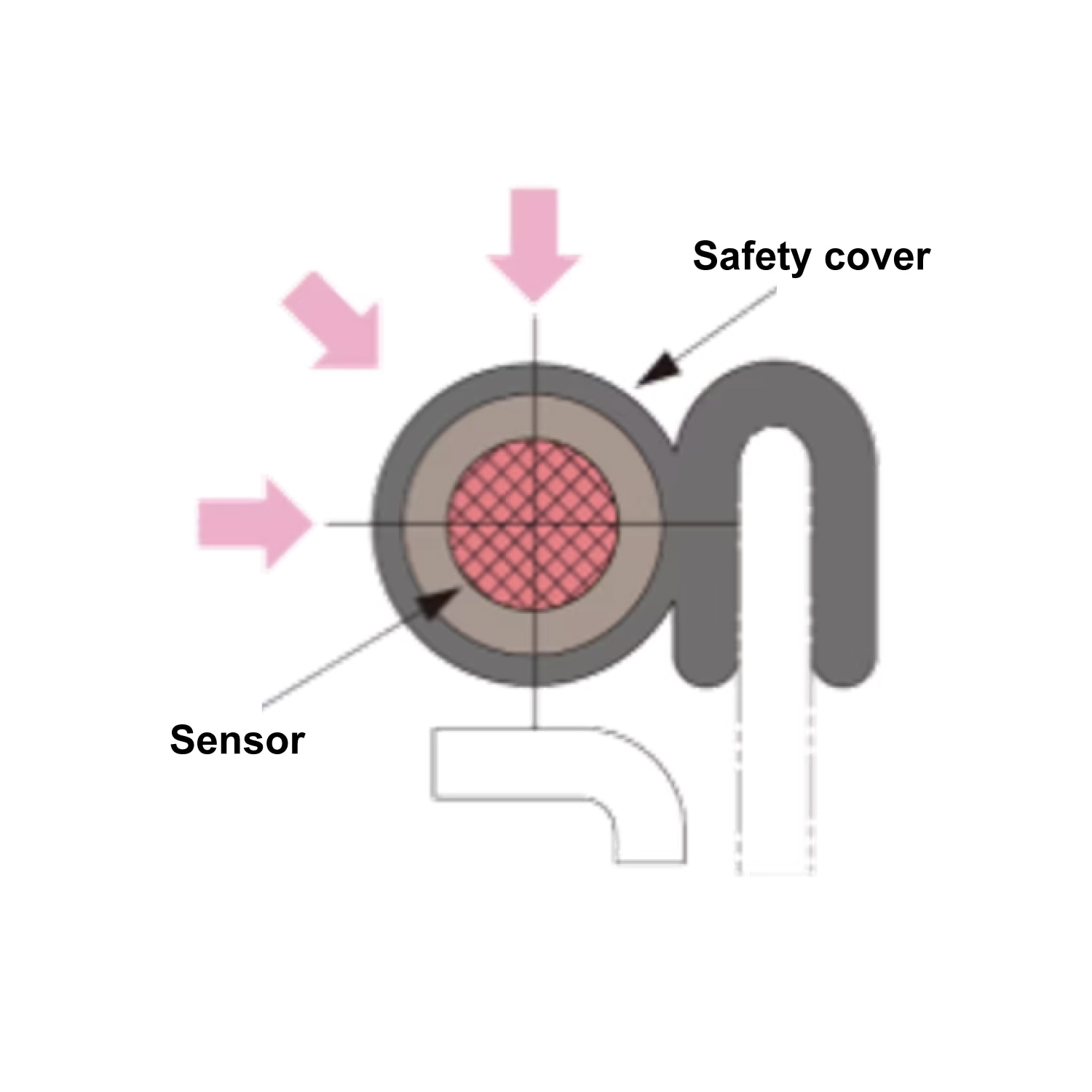

repeatedly

Since the cable switch is protected by a safety cover, it has excellent weather resistance and durability, and can be used for a long time while maintaining high detection sensitivity.

If the cable is damaged, parts can be replaced together with the safety cover.

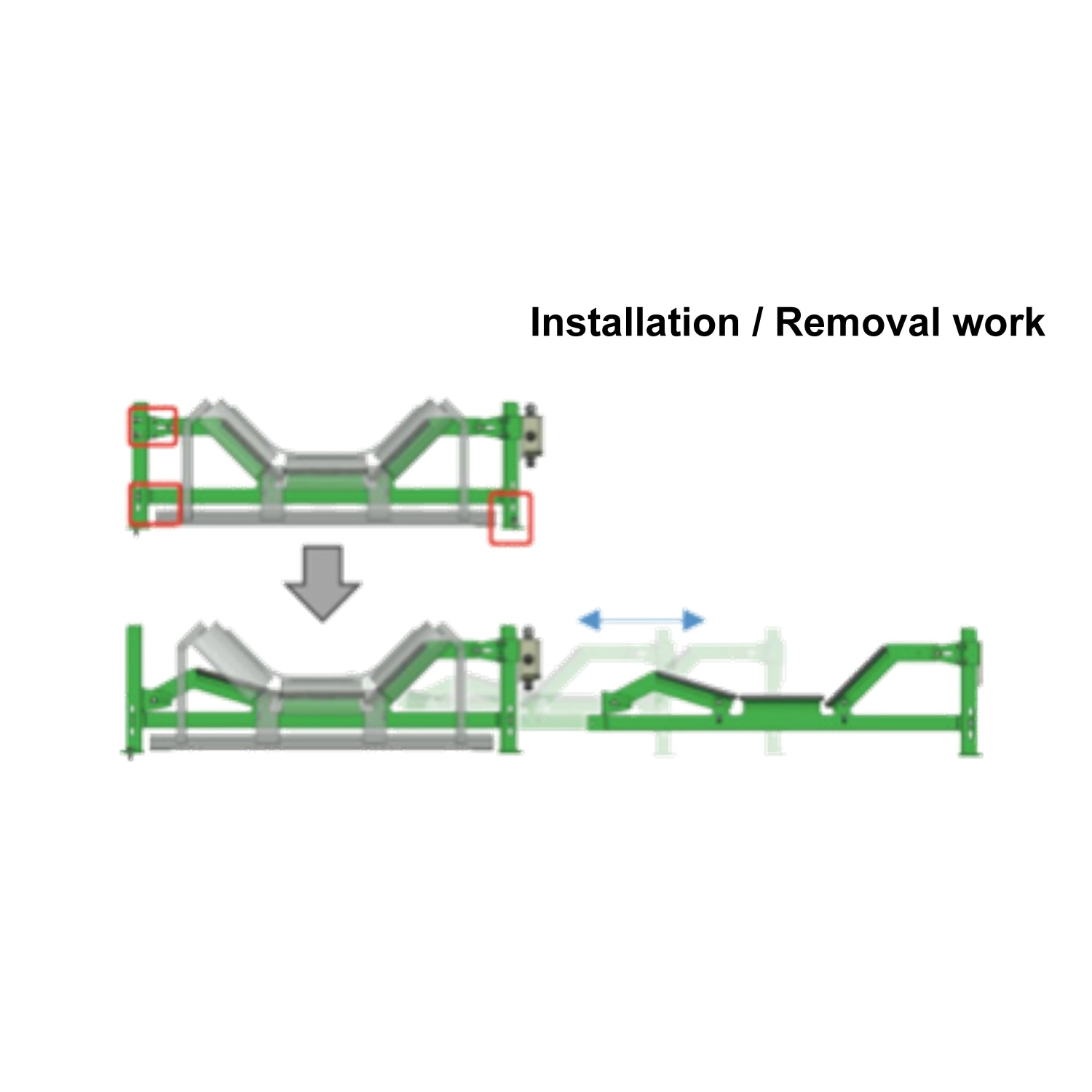

Easy to install

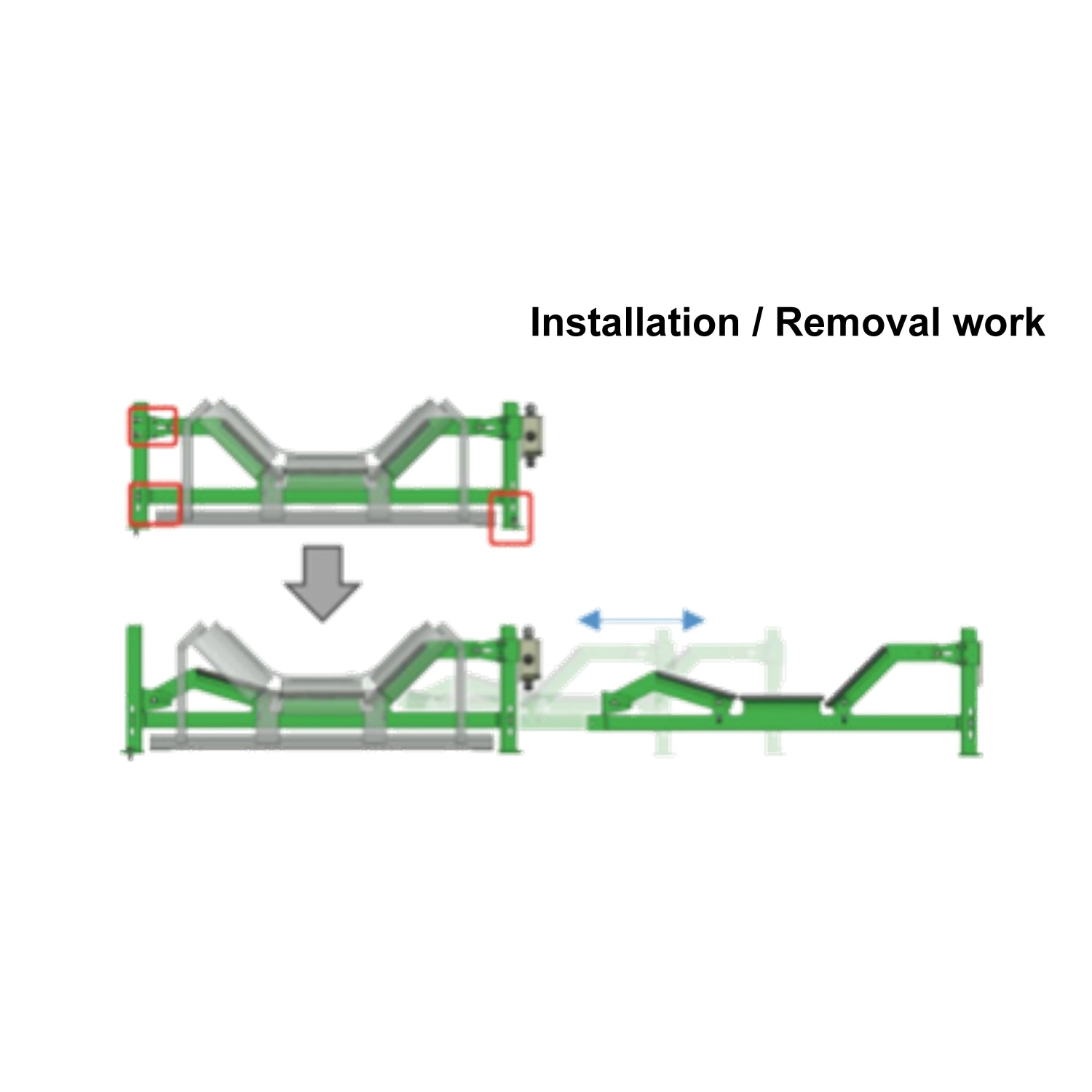

Since trough angle is variable, it can be put in and taken out by putting it in a flat state and sliding it from side of belt when installing or removing it. Therefore, there is no work burden such as lifting belt.

*We also manufacture fixed type in which trough angle is not variable.

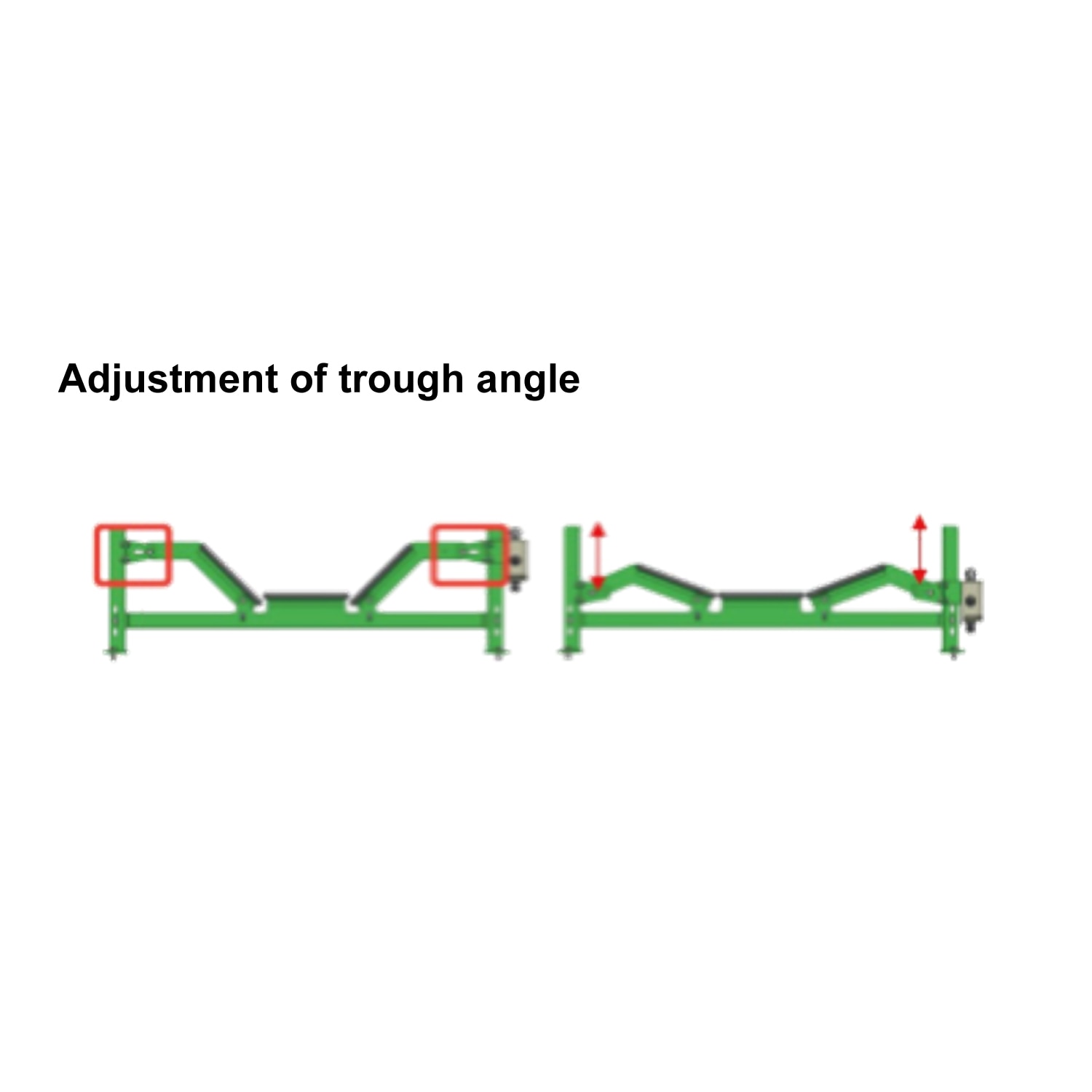

Adjust according

to trough angle

on site

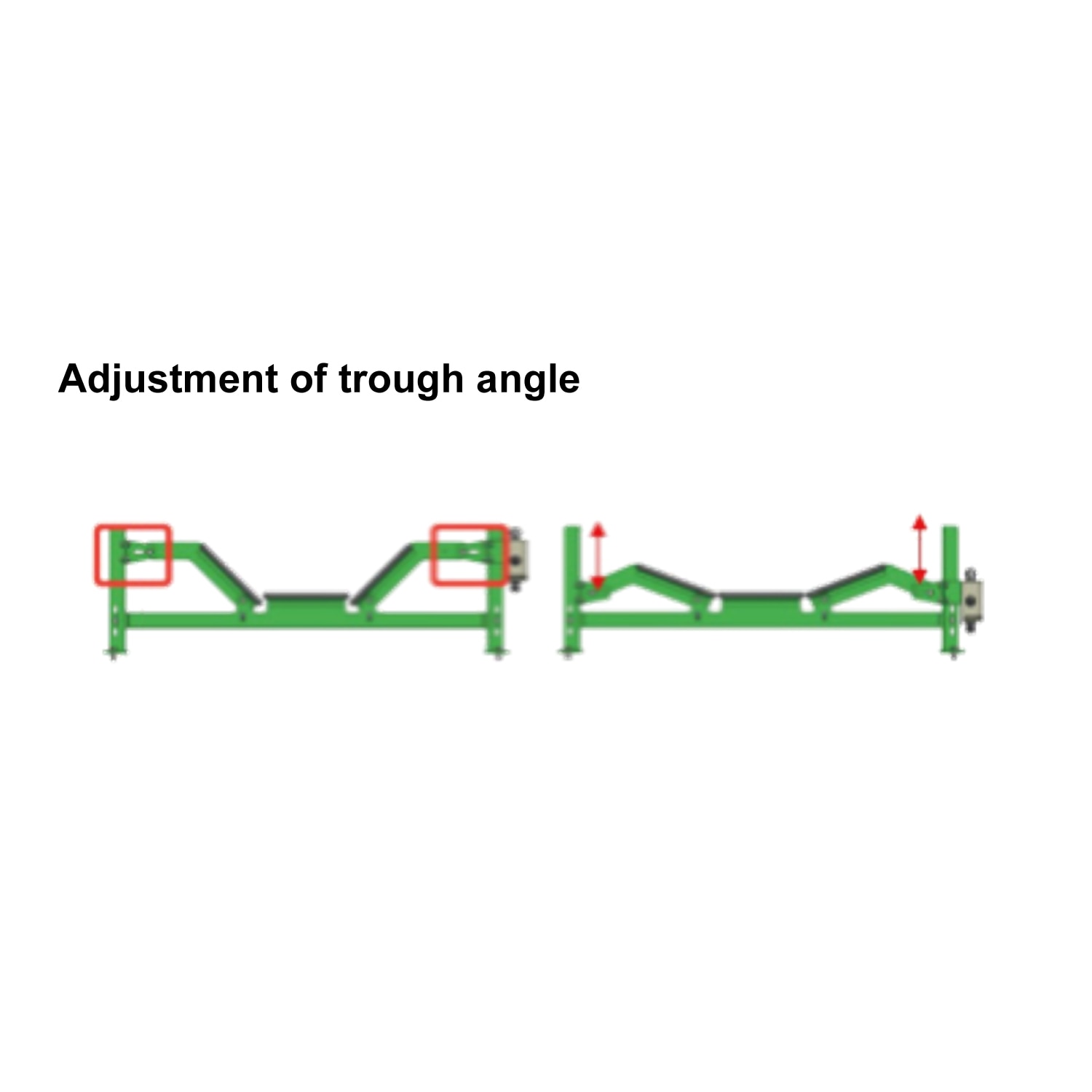

The angle of sensor can be adjusted according to trough angle of the conveyor. Even if the trough angle is not known in advance, it is easy to handle because it can be adjusted on site.

Made to order

It can also be used with a uniquely designed belt conveyor. We also design and manufacture vertical tear detectors for existing conveyors based on facility drawings.

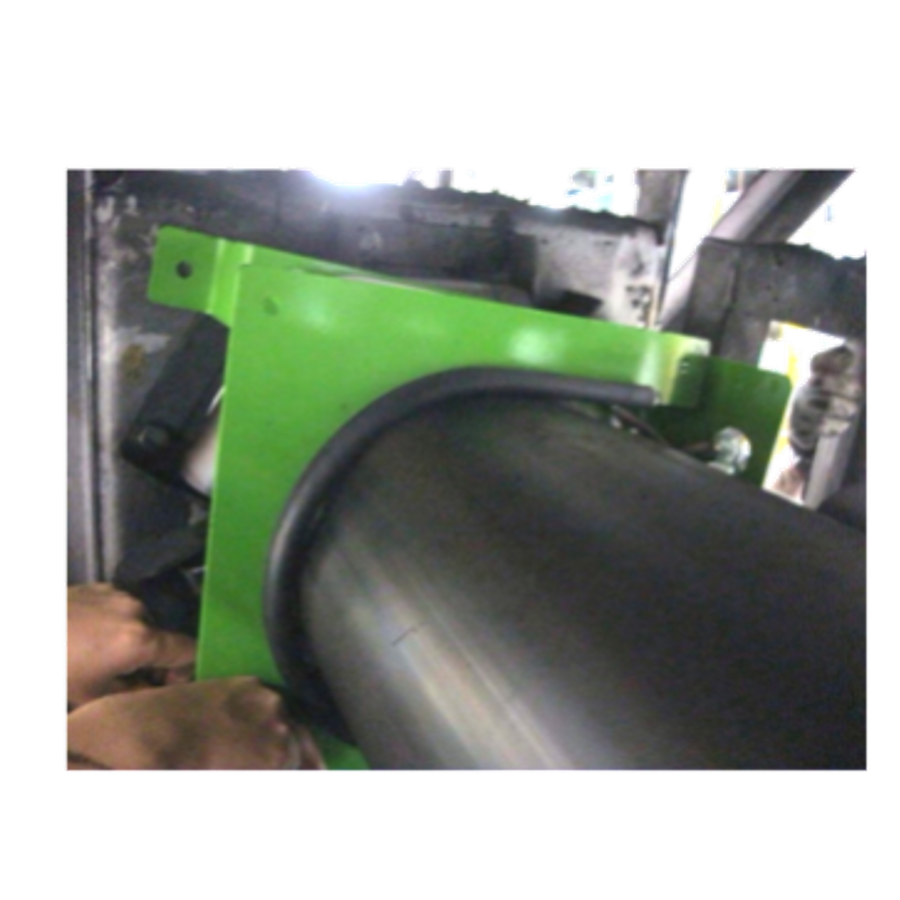

Example: pipe conveyor

*For details, please refer to the instruction manual.

Operating principle

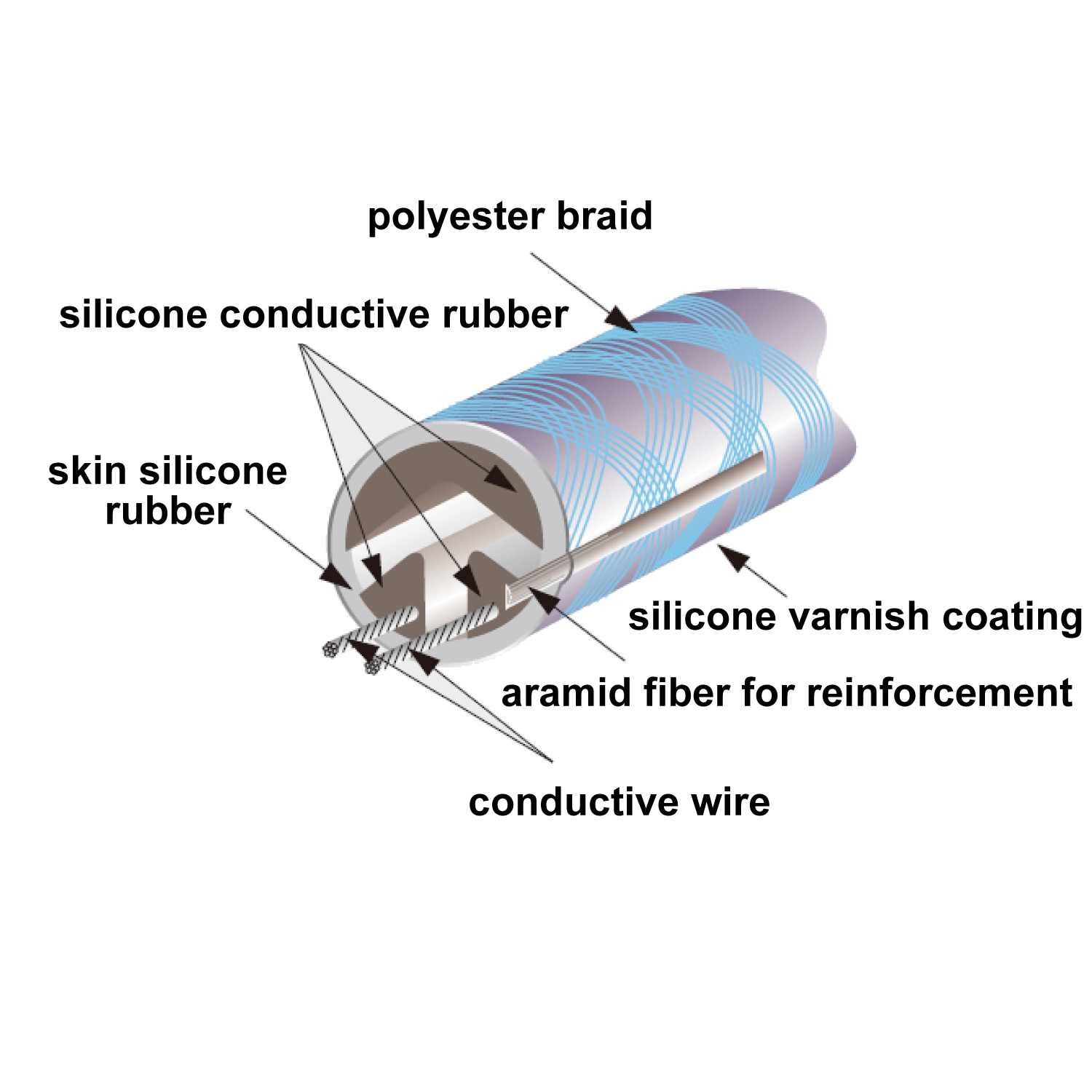

Sensor of Belt Tear Detector is tubular with separate positive and negative cables. These cables are energized by converter.

When this tube is crushed by an external force, the positive and negative cables inside come into contact with each other and are detected by conduction.

By placing this sensor next to impact roller under chute, if a foreign object penetrates the belt, the foreign object presses the sensor (tube) and activates the sensor.

\ Download or Request for quote /

How to use?

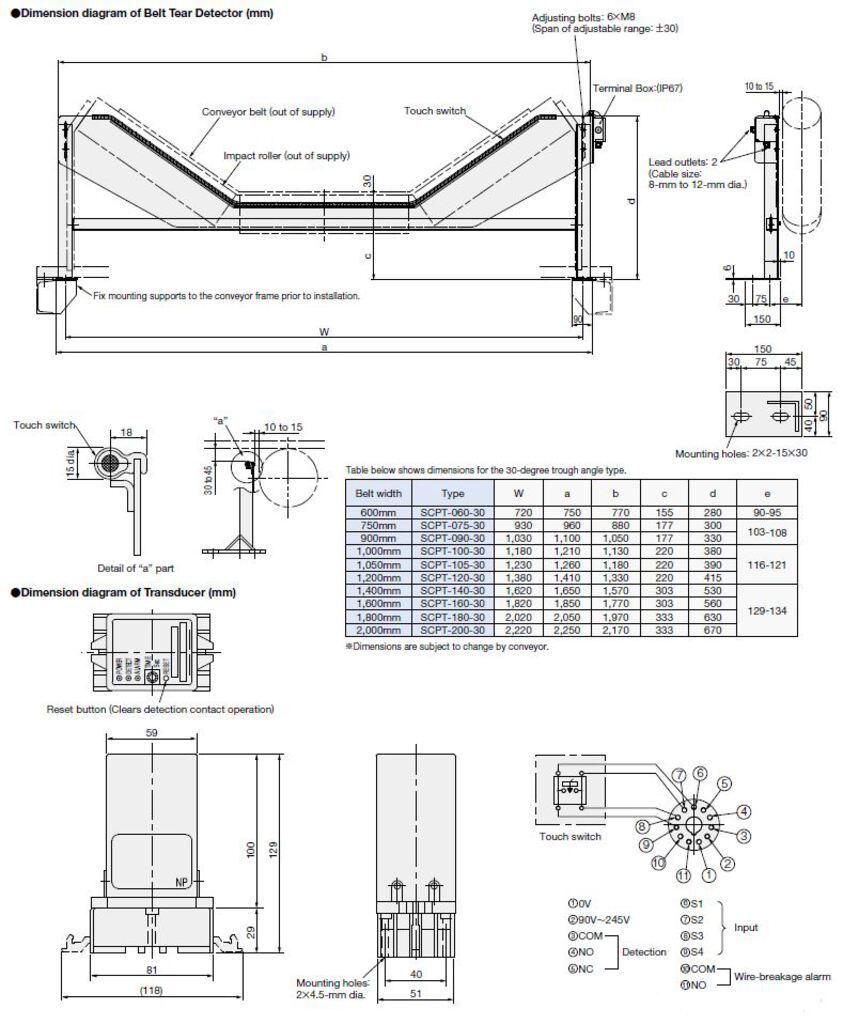

1.Determine mounting position

Install the sensor under the chute where vertical tearing is a problem.

Prepare as many sensors as there are rollers under the chute. The reason for this is that once the foreign matter penetrates the belt, it will catch on the rollers and start tearing.

2. Mounting

Mechanism that allows trough angle to be freely adjusted is adopted in consideration of on-site installation. Since there is no need to lift belt, chain blocks are unnecessary and can be easily installed and removed.

Work time can be reduced to 1/2 or less compared to conventional method.

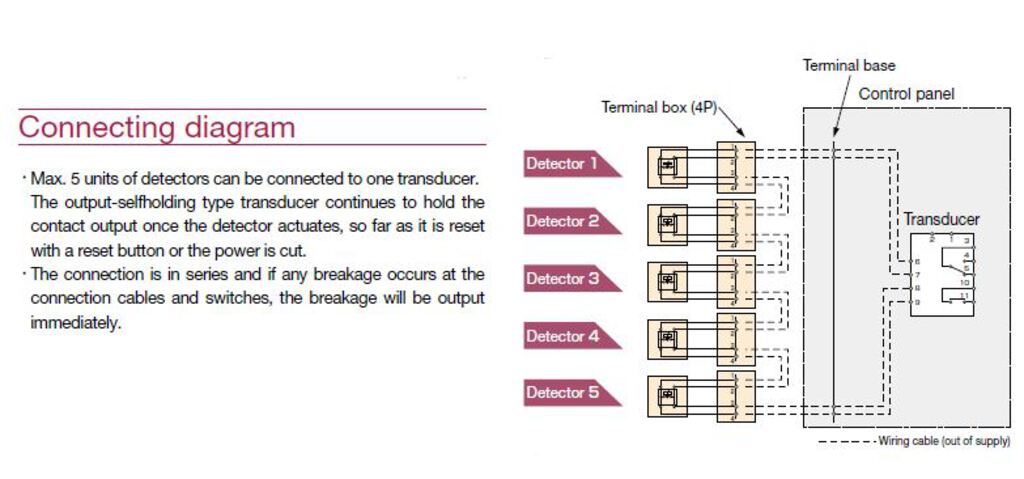

3. Wiring

A maximum of 5 sensors can be attached to one converter.

Since converter uses contact hold output, once an operation is detected, contact output continues

unless the reset button is pressed to cancel or the power is turned off . Connected in series, when a disconnection accident occurs in connection cable or switch, disconnection detection is output immediately.

4. Adjustment

Trough angle can be easily adjusted on site by removing two screws.

*For details, please refer to the instruction manual.

Maintenance

- Please check regularly once every 1 to 3 months.

- Frequent inspections are required, especially in places where there is a large amount of transport or where there is a lot of sediment.

- If there is more than 1 cm of deposit on or around the sensor, remove it.

- In locations subject to strong vibration, check for loose mounting bolts.

\ Download or Request for quote /

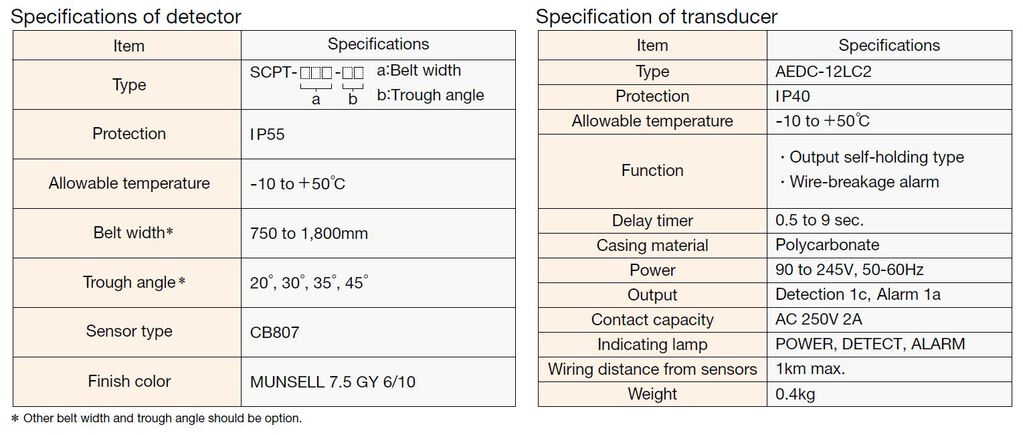

Model lineup

This is a type with fixed trough angle (fixed at specified angle).

Please inquire about trough angle adjustable type.

\ Download or Request for quote /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.