Belt Conveyor Troubles and Solutions

Belt Conveyor Safety Operation

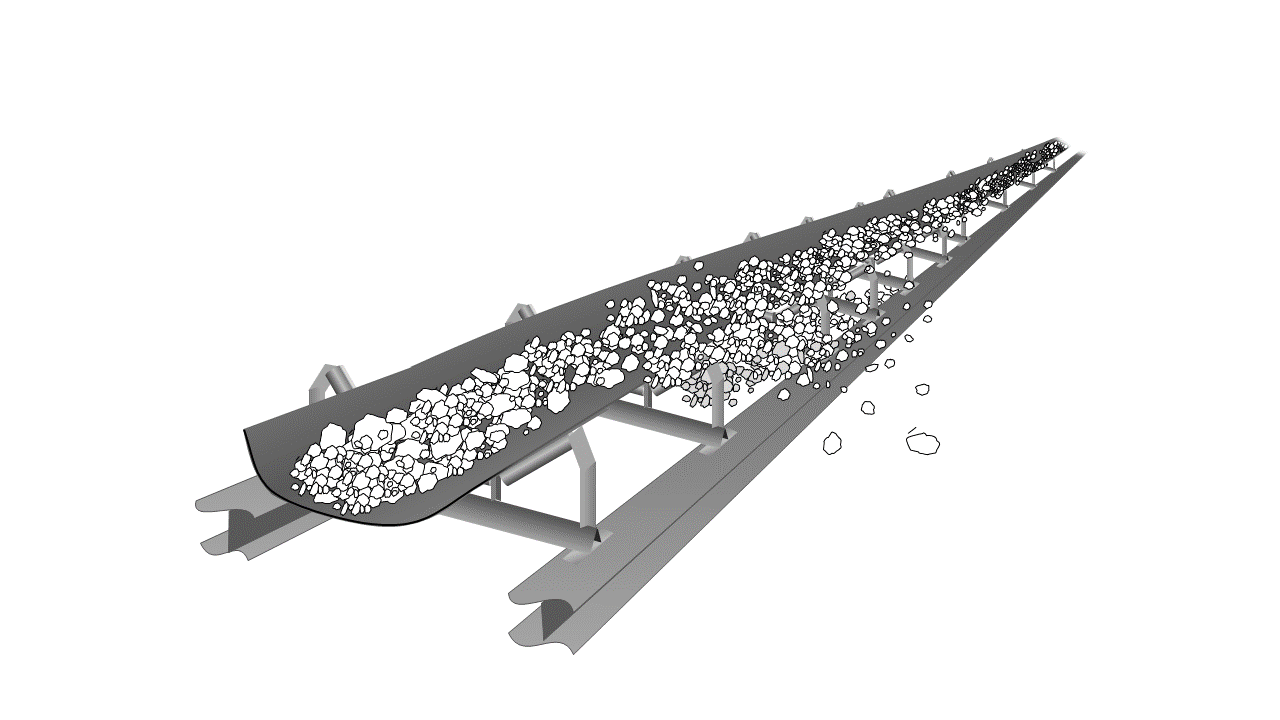

Belt conveyors are effective for transporting large amount of raw material or fuel and so widely used in material industry, energy industry and so on.

Accidents are relatively decreasing nowadays but it may cause various troubles when facilities become old.

So, it is important to understand characteristics of belt conveyors for stable operation of belt conveyors and safety of workers.

This article shows such typical troubles and those countermeasures.

Accidents are relatively decreasing nowadays but it may cause various troubles when facilities become old.

So, it is important to understand characteristics of belt conveyors for stable operation of belt conveyors and safety of workers.

This article shows such typical troubles and those countermeasures.

Typical Troubles and Accidents

Serious troubles or accidents may occur in conveyor belt operation, such as:

- Material drop: Material falls off the belt due to improper loading or worn edges.

- Fire accidents: These can occur due to heat from friction or electrical failures, and are especially dangerous when dealing with flammable materials.

- Conveyor belt rip accidents: Wrong obstacles trasported with material may stick into the belt and tear it.

- Belt cut break accidents: Belt breaks due to excessive tension or the inclusion of foreign objects.

- Blocking chute: Chute gets clogged due to improper material input or poor design.

- Human injury: Workers are injured by being caught or pinched in rotating parts

To prevent these problems, regular inspections, installation of appropriate safety devices, and safety training for workers are essential. Other important measures include the introduction of emergency stop systems and the maintenance of fire prevention equipment.

Cause of Troubles and Solutions

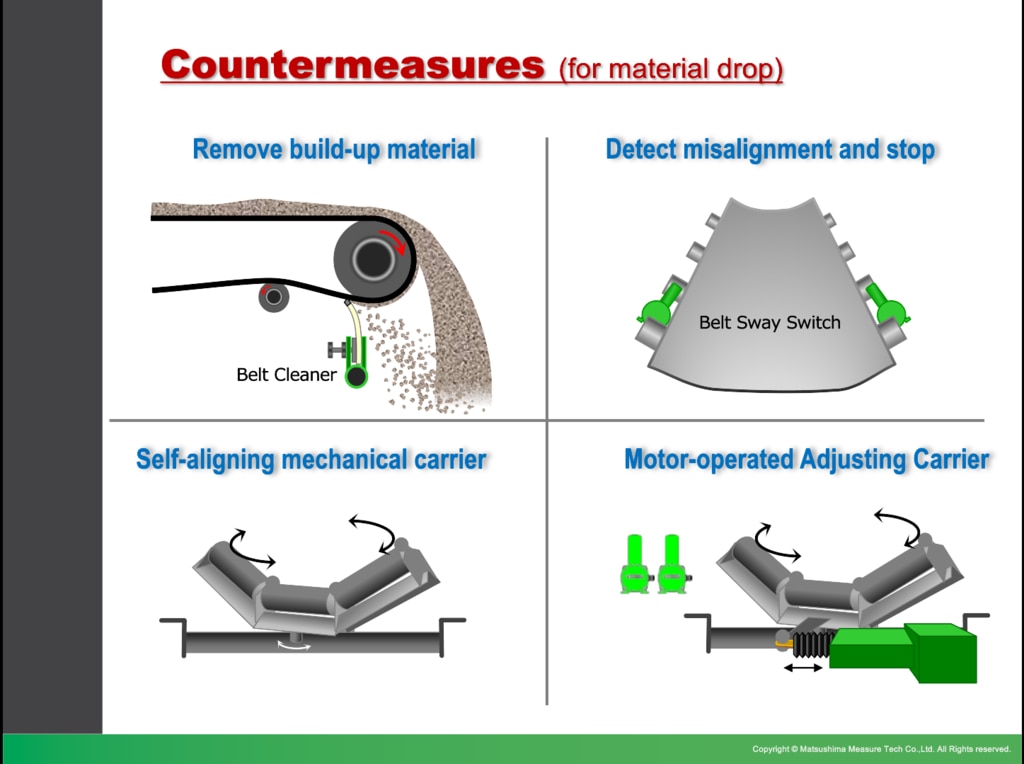

1. Material Drop

Popular causes of this trouble are following:

1. Pulley or roller has got dirt, build-up, adhesion, etc.

2. Roller is not rotating properly or broken.

3. Transporting material is changed. (loaded on side, etc.)

4. Skirt rubber is damaged or load material is bitten inside.

5. Conveyor belt is damaged.

Then, it may cause; "conveyor belt snaking (or misalignment)" ➡ "material drop" ➡ "production loss and maintenance cost raise".

Following equipment is effective for preventing this trouble:

1. Pulley or roller has got dirt, build-up, adhesion, etc.

2. Roller is not rotating properly or broken.

3. Transporting material is changed. (loaded on side, etc.)

4. Skirt rubber is damaged or load material is bitten inside.

5. Conveyor belt is damaged.

Then, it may cause; "conveyor belt snaking (or misalignment)" ➡ "material drop" ➡ "production loss and maintenance cost raise".

Following equipment is effective for preventing this trouble:

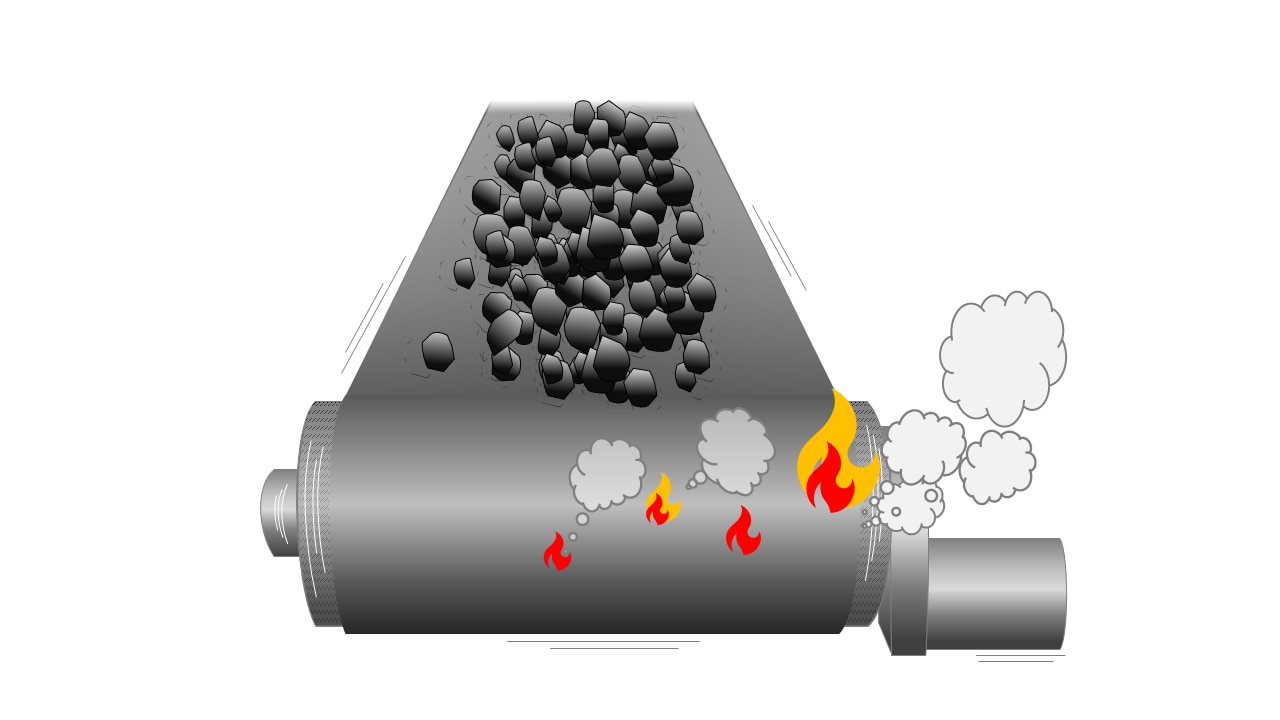

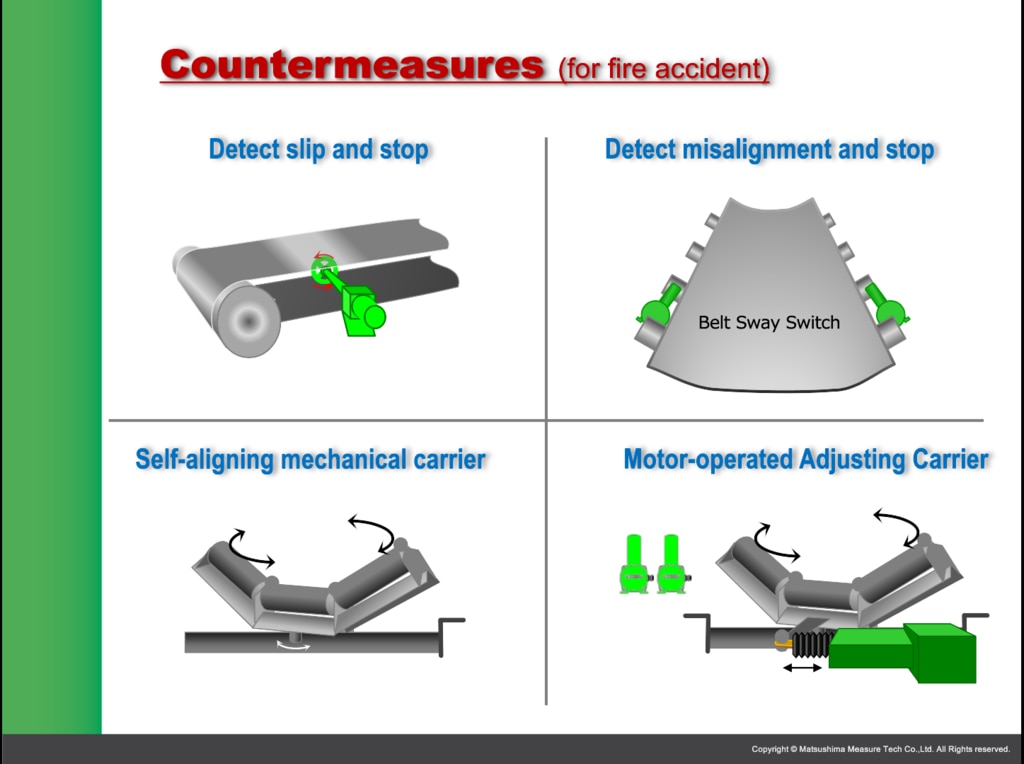

2. Fire Accident

Popular causes of this trouble are following:

1. Belt slip between conveyor belt and drive pulley.

2. Heat due to malfunction or rotating parts (bearing, roller, etc.).

3. Friction heat between misaligned belt and frame.

4. Heat generated from accumulated dust at roller stand, etc.

5. Ignition from the site work using fire.

Then, it may cause; "fire accident" ➡ "production loss, maintenance cost raise, human injury, health damage and air pollution".

Following equipment is effective for preventing this trouble:

1. Belt slip between conveyor belt and drive pulley.

2. Heat due to malfunction or rotating parts (bearing, roller, etc.).

3. Friction heat between misaligned belt and frame.

4. Heat generated from accumulated dust at roller stand, etc.

5. Ignition from the site work using fire.

Then, it may cause; "fire accident" ➡ "production loss, maintenance cost raise, human injury, health damage and air pollution".

Following equipment is effective for preventing this trouble:

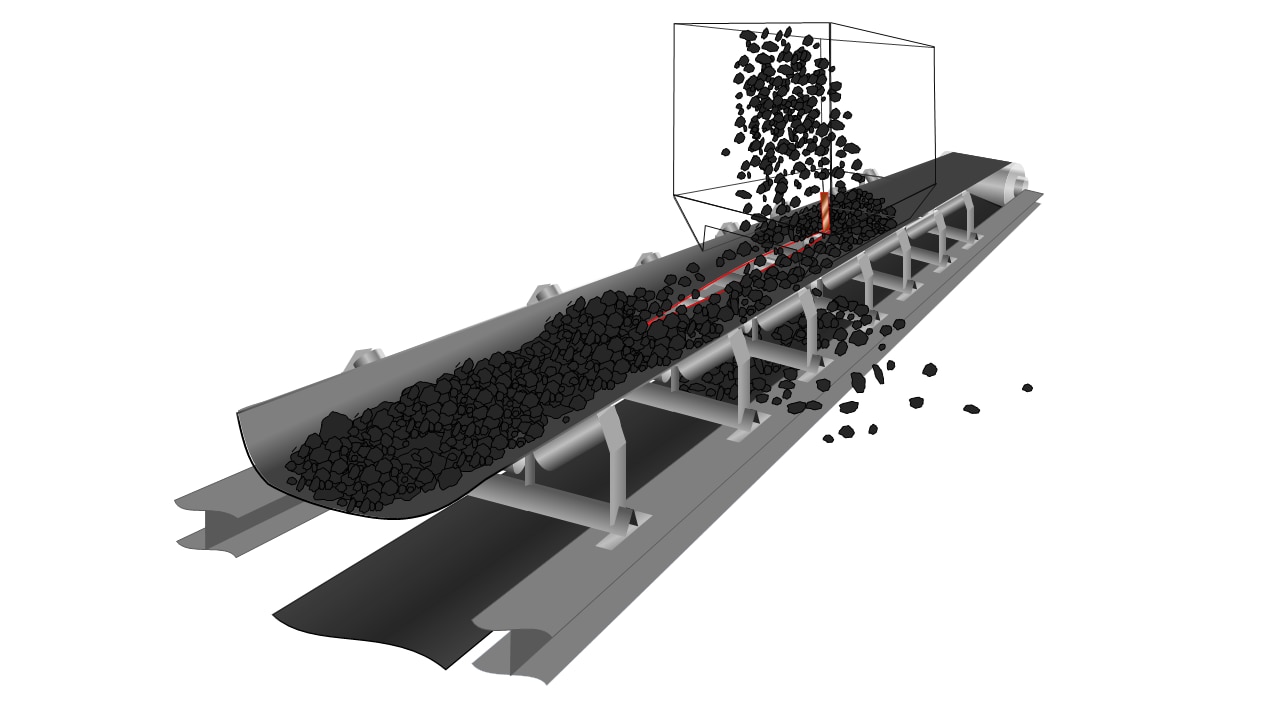

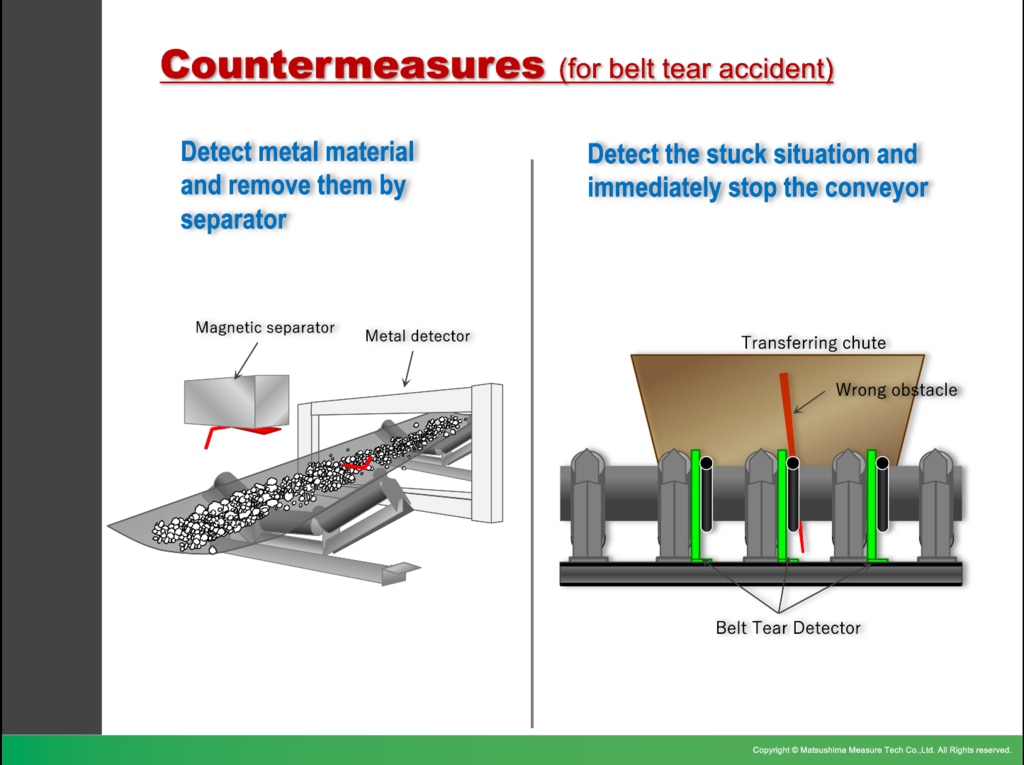

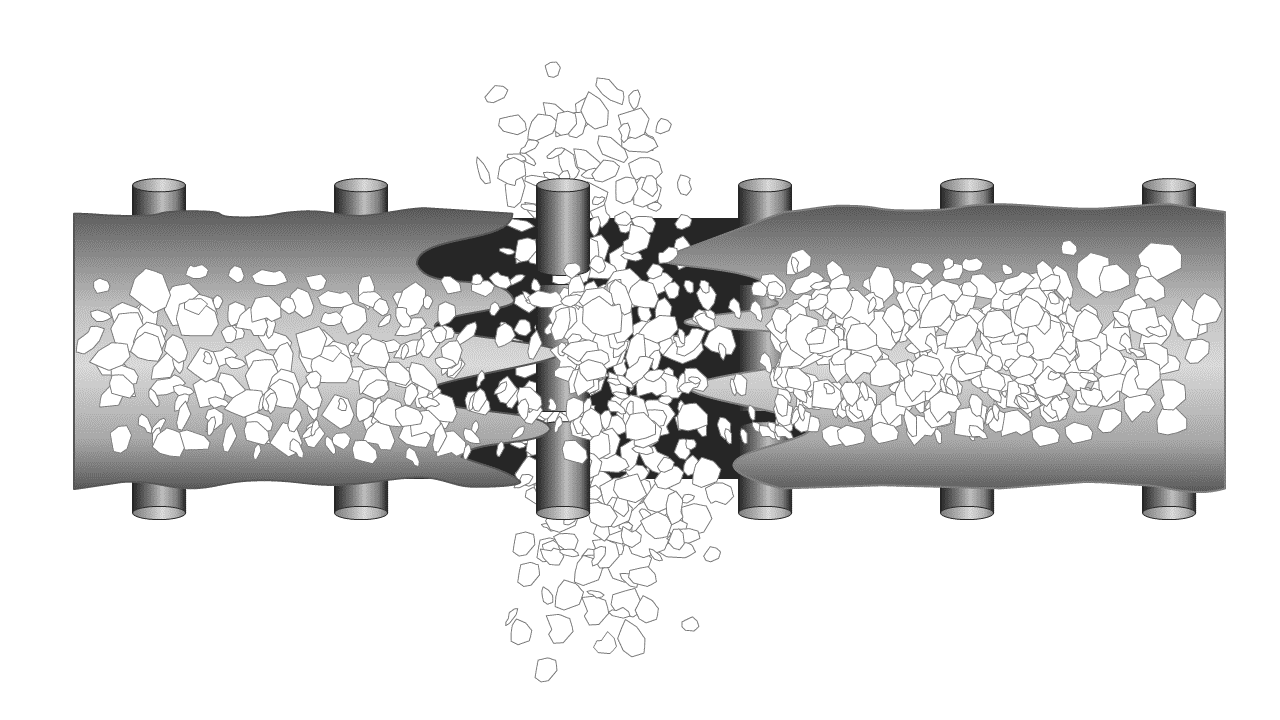

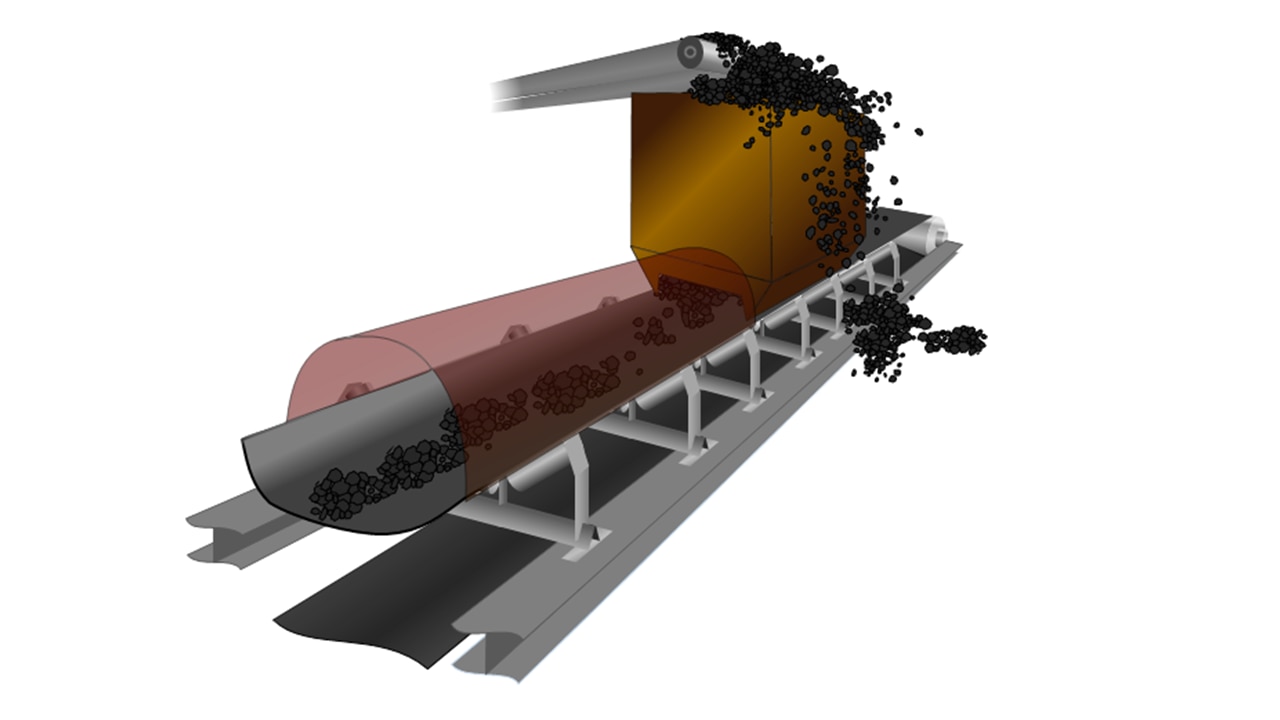

3. Conveyor Belt Rip (tear) Accident

Popular cause of this trouble is following:

Wrong material or obstacles like sharp solid or metal mixed in the transporting material sticks through the conveyor belt and stuck in the impact roller just below the transferring chute.

Then, it may cause; "belt rip accident" ➡ "production loss and maintenance cost raise".

Following equipment is effective for preventing this trouble:

Wrong material or obstacles like sharp solid or metal mixed in the transporting material sticks through the conveyor belt and stuck in the impact roller just below the transferring chute.

Then, it may cause; "belt rip accident" ➡ "production loss and maintenance cost raise".

Following equipment is effective for preventing this trouble:

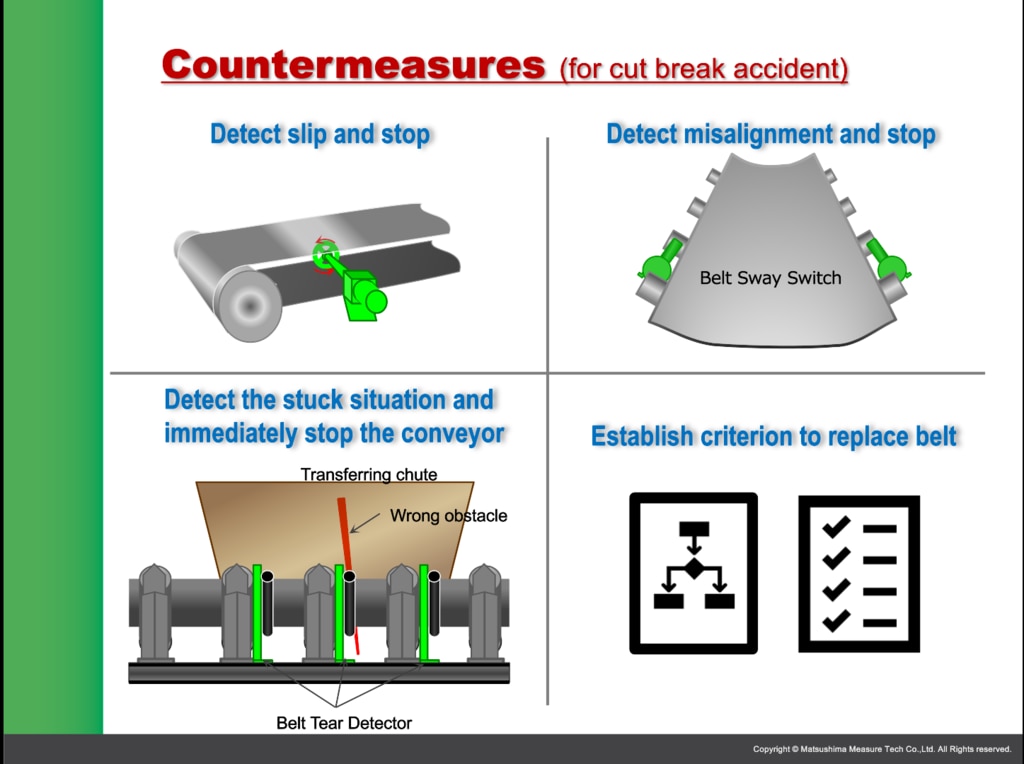

4. Belt Cut Break Accident

Popular causes of this trouble are following:

1. Frequent belt slip between conveyor belt and drive pulley.

2. Rubber of belt surface is worn and the fabric is exposed.

3. Crack or scratch on the inner fabric observed 10% or over.

4. Bear tear damage or scratch.

5. There are many repair portions.

Then, it may cause; "belt cut break accident" ➡ "production loss, maintenance cost raise and serious human injury accident".

Following equipment is effective for preventing this trouble:

1. Frequent belt slip between conveyor belt and drive pulley.

2. Rubber of belt surface is worn and the fabric is exposed.

3. Crack or scratch on the inner fabric observed 10% or over.

4. Bear tear damage or scratch.

5. There are many repair portions.

Then, it may cause; "belt cut break accident" ➡ "production loss, maintenance cost raise and serious human injury accident".

Following equipment is effective for preventing this trouble:

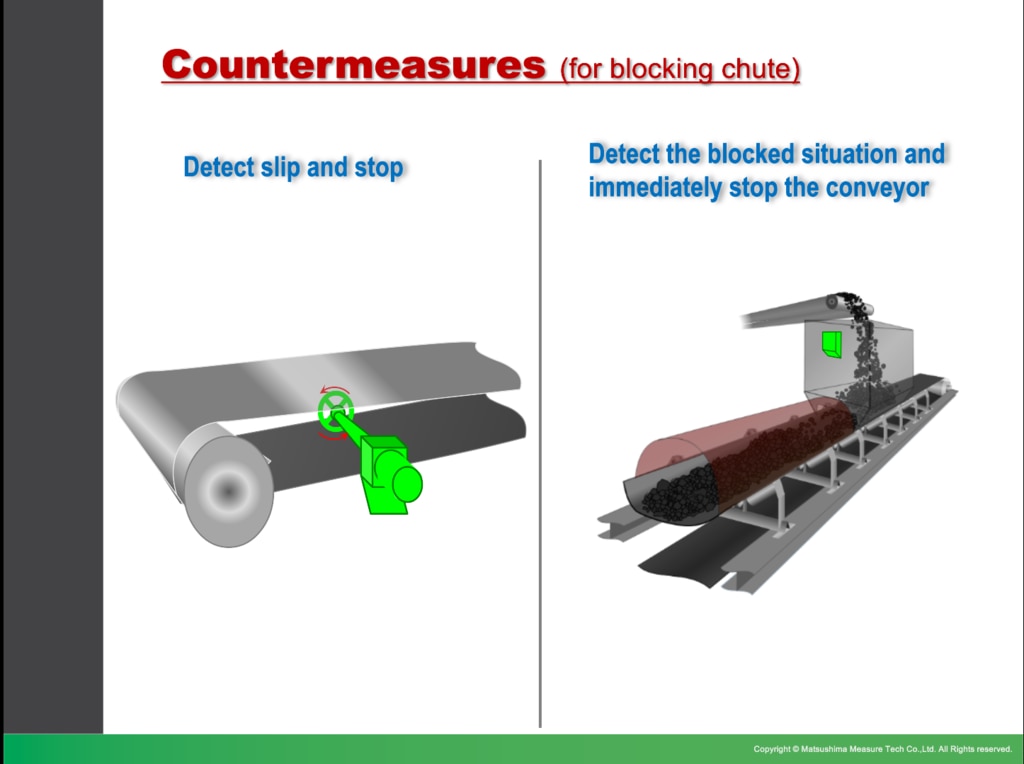

5. Blocking Chute

Popular causes of this trouble are following:

1. Transferring conveyor has conveyor belt slipping.

2. Transporting material is stuck in the transferring chute and not charged on the belt conveyor.

Then, it may cause; "blocking chute accident" ➡ "production loss, maintenance cost raise and environmental pollution".

Following equipment is effective for preventing this trouble:

1. Transferring conveyor has conveyor belt slipping.

2. Transporting material is stuck in the transferring chute and not charged on the belt conveyor.

Then, it may cause; "blocking chute accident" ➡ "production loss, maintenance cost raise and environmental pollution".

Following equipment is effective for preventing this trouble:

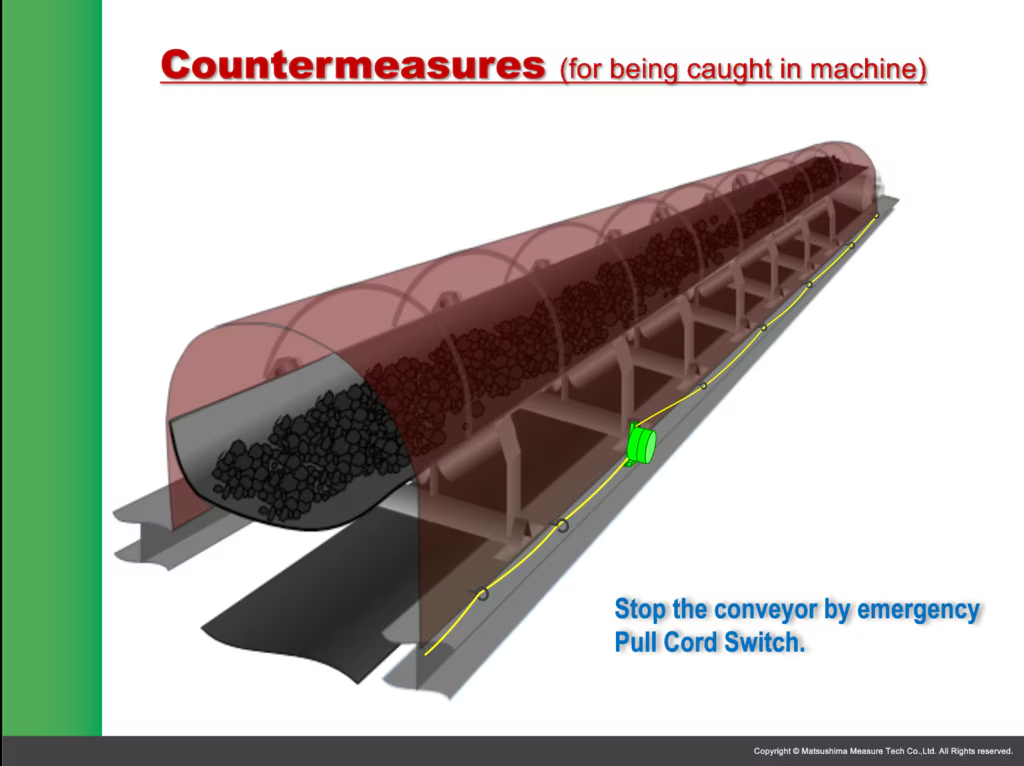

6. Caught In The Machine

Popular causes of this trouble are following:

1. Someone started the conveyor during the repair work.

2. Self-driving system started the conveyor during the repair work.

3. Build-up material removing work without stopping the conveyor.

4. Unintentionally touched with rotating pulley at the conveyor not having the safety cover.

Then, it may cause; "human caught in the machine" ➡ "serious human injury and production loss".

Following equipment is effective for preventing this trouble:

1. Someone started the conveyor during the repair work.

2. Self-driving system started the conveyor during the repair work.

3. Build-up material removing work without stopping the conveyor.

4. Unintentionally touched with rotating pulley at the conveyor not having the safety cover.

Then, it may cause; "human caught in the machine" ➡ "serious human injury and production loss".

Following equipment is effective for preventing this trouble:

Belt Conveyor Equipment

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

Please feel free to contact us if you have any inquiries.

Click here to download documents.

© Matsushima Measure Tech Co., Ltd.