Belt Conveyor Protection Equipment

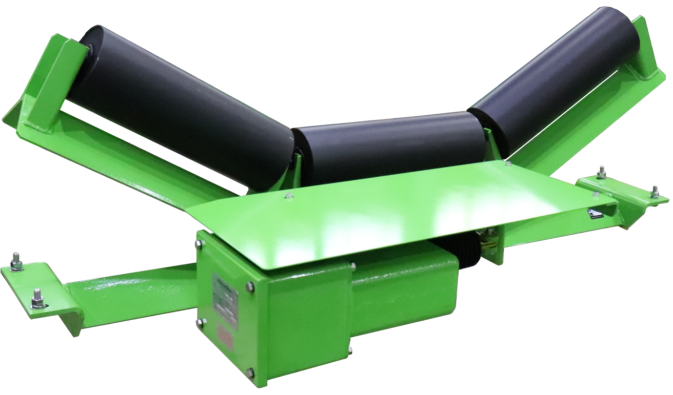

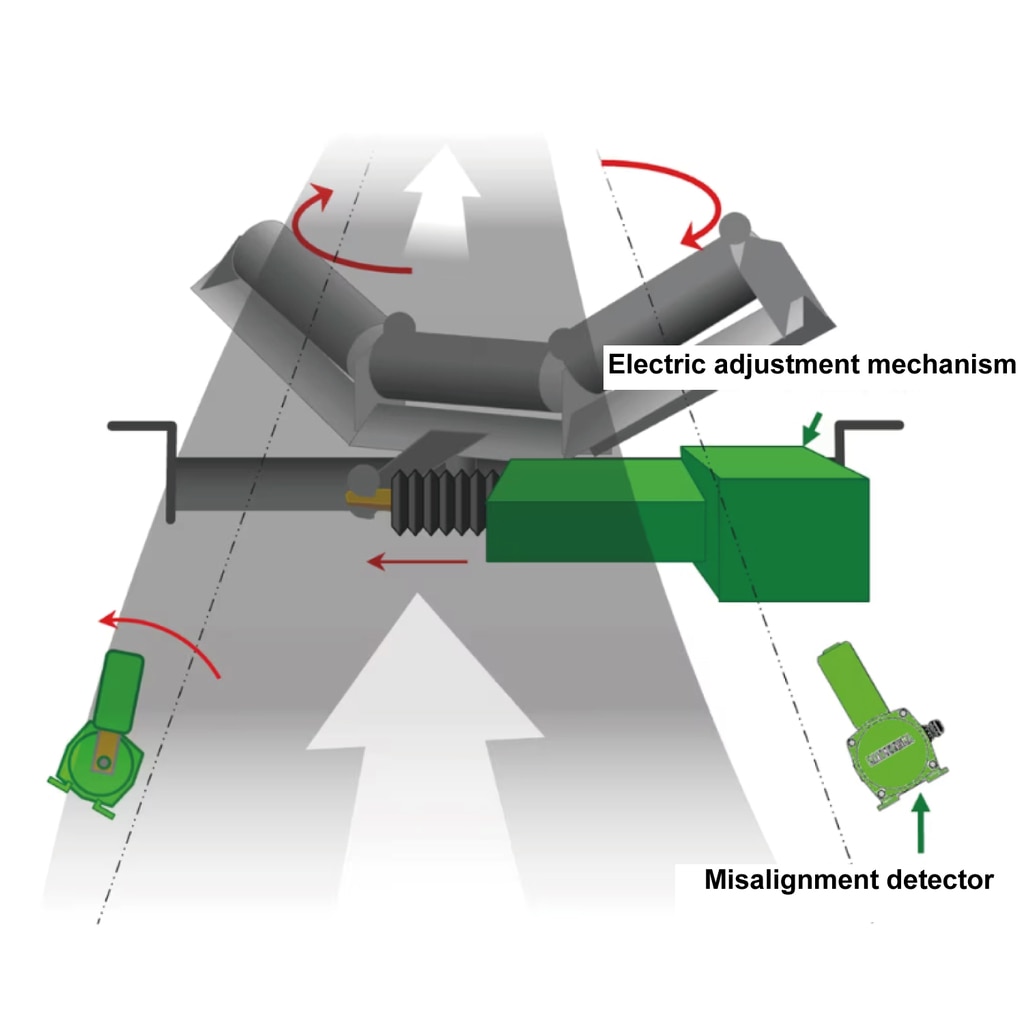

Motor-operated Adjustment Carrier is a device that forcibly and automatically corrects belt misalighment with the power of a motor.

Actual installation on site

Advantages

- Belt conveyors that tend to misalign or shift to one side can be operated without stopping as much as possible.

- No falling or damage of transported goods. Reduce unnecessary spending.

- Belt damage is eliminated and belt life is extended.

\ Download or Request for quote /

Features of Motor-operated Adjustment Carrier

The main features of Motor-operated Adjustment Carrier are as follows.

Forced Auto Correction

at Motor

For conveyors with a short machine length of 10 m or less, general self-alignment lacks force and effect is weak, but Motor-operated Adjustment Carrier can be forcibly corrected, contributing to continuous conveyor operation.

Supports correction

on the return side

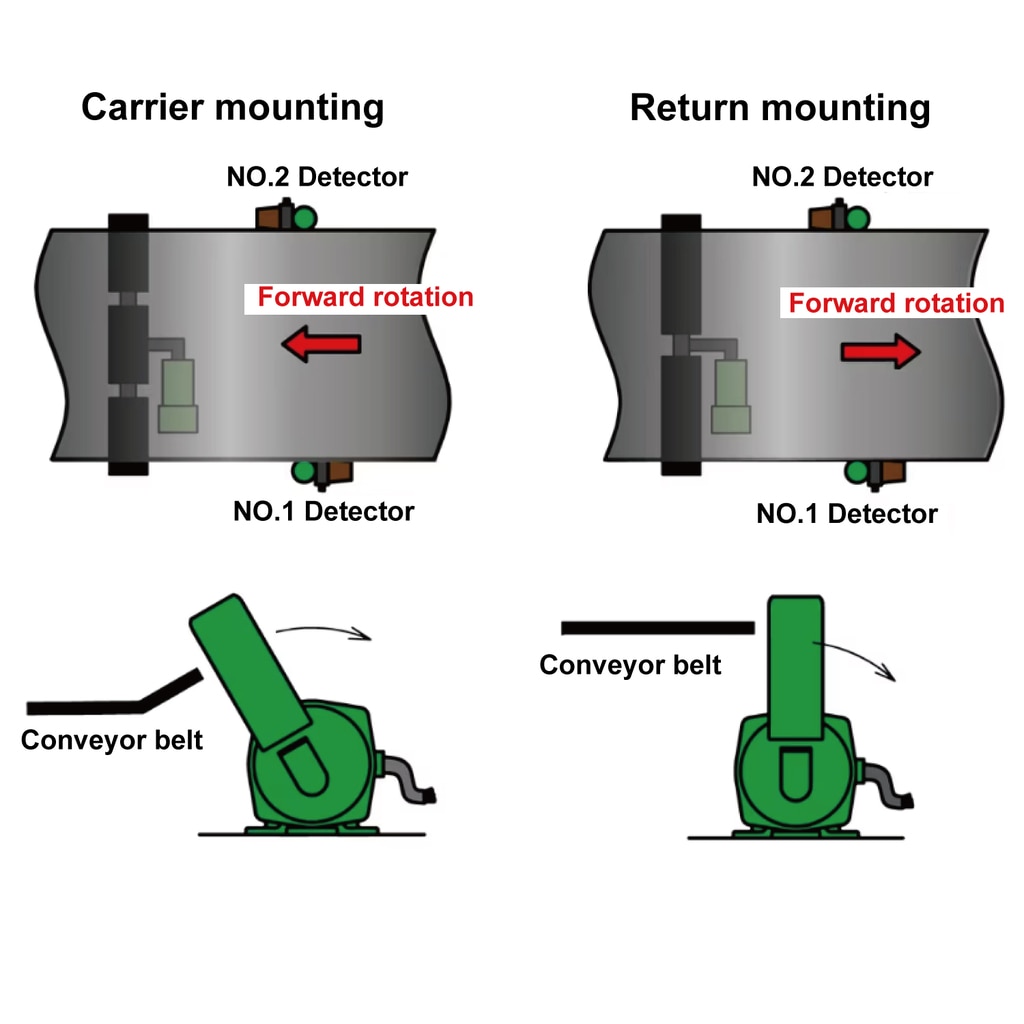

Belt misalighment occurs in various places, so we manufacture both the carrier side and the return side.

Compatible with

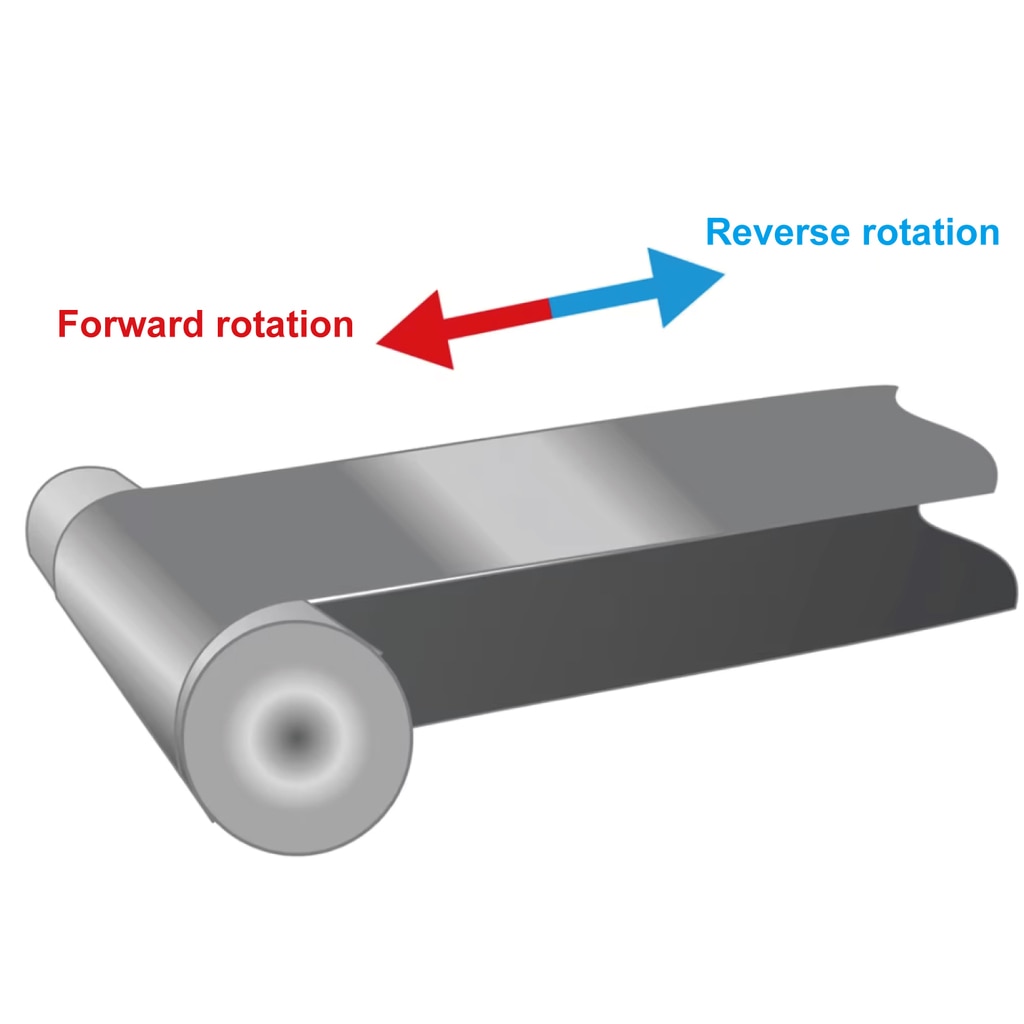

reversible conveyors

By adding an optional reversible relay unit, it can also be used for reversible conveyors.

*For details, please refer to the instruction manual.

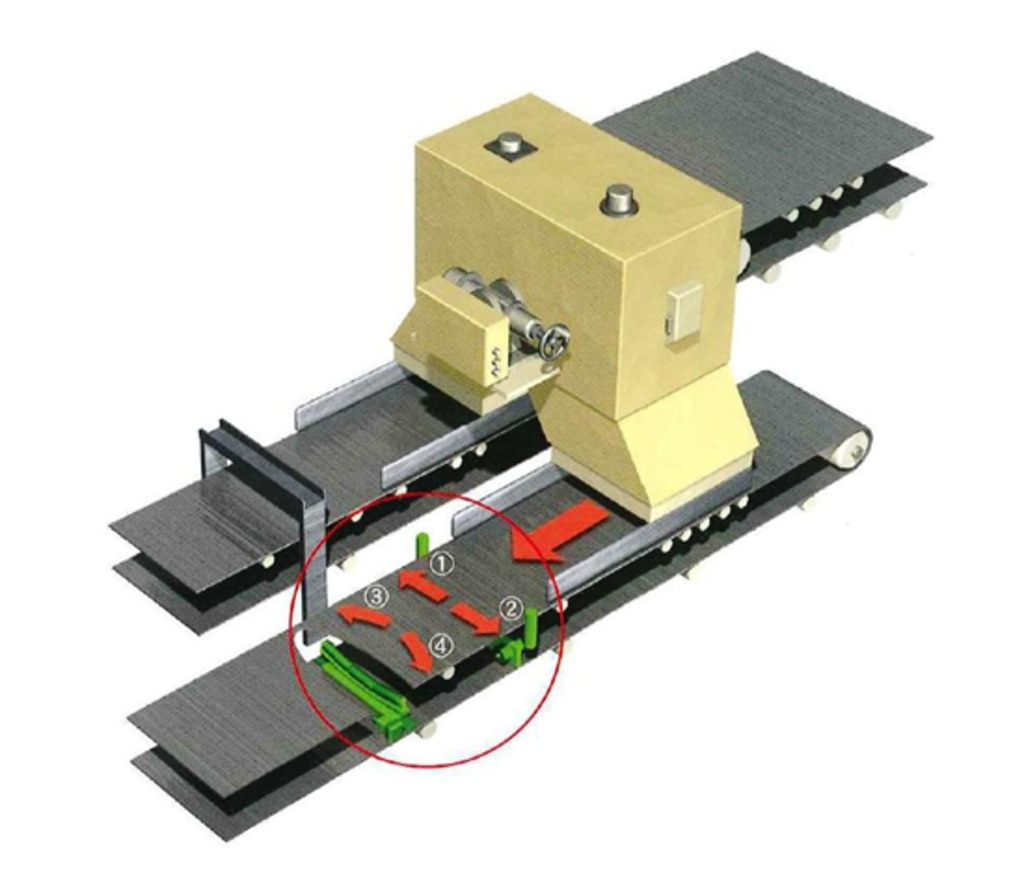

Operating principle

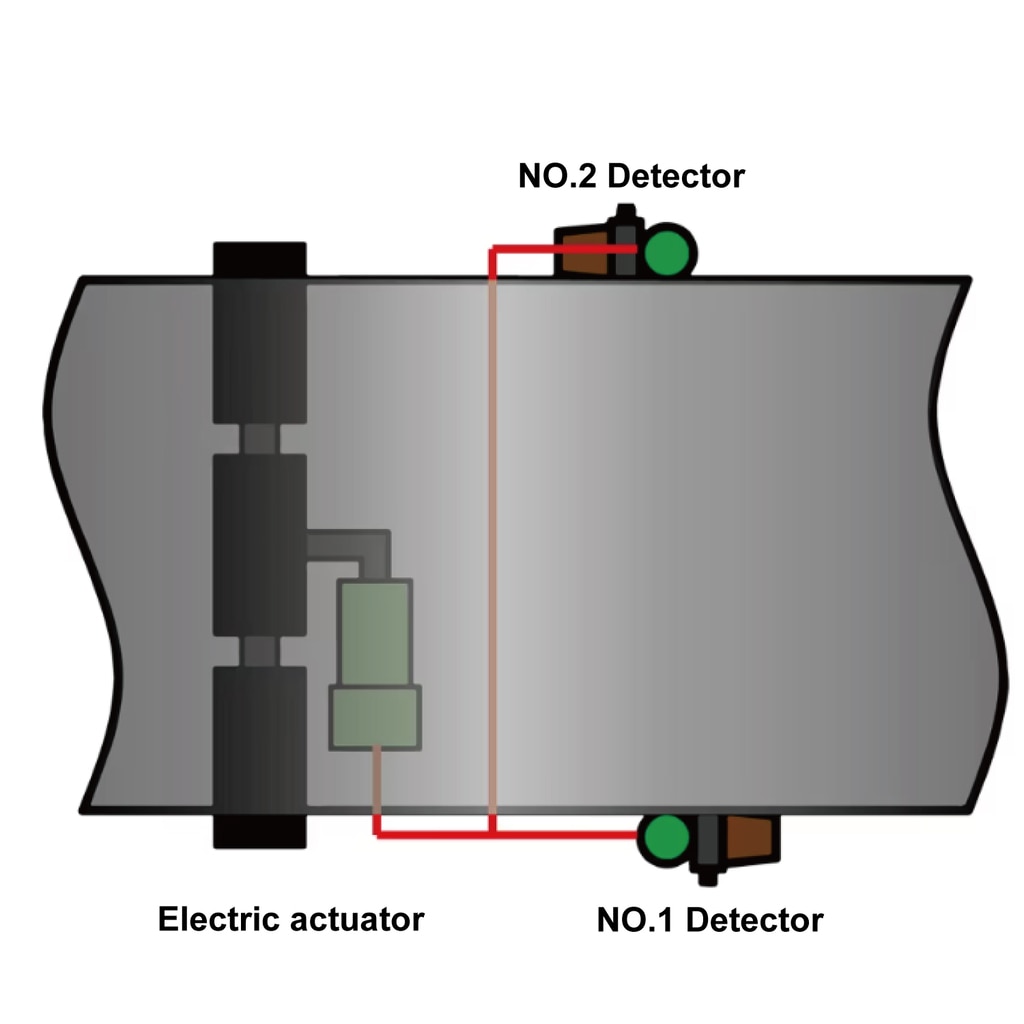

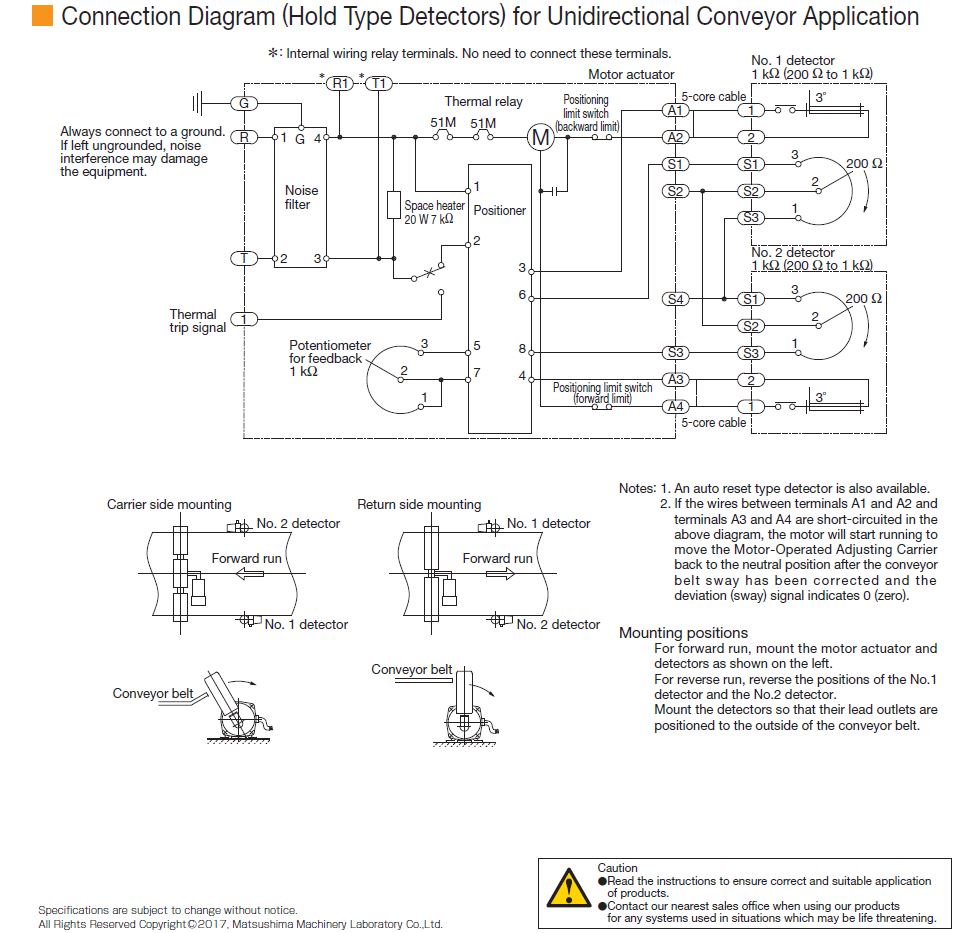

Motor-operated Adjustment Carrier consists of a detector that detects meandering and an electric actuator that corrects misalighment.

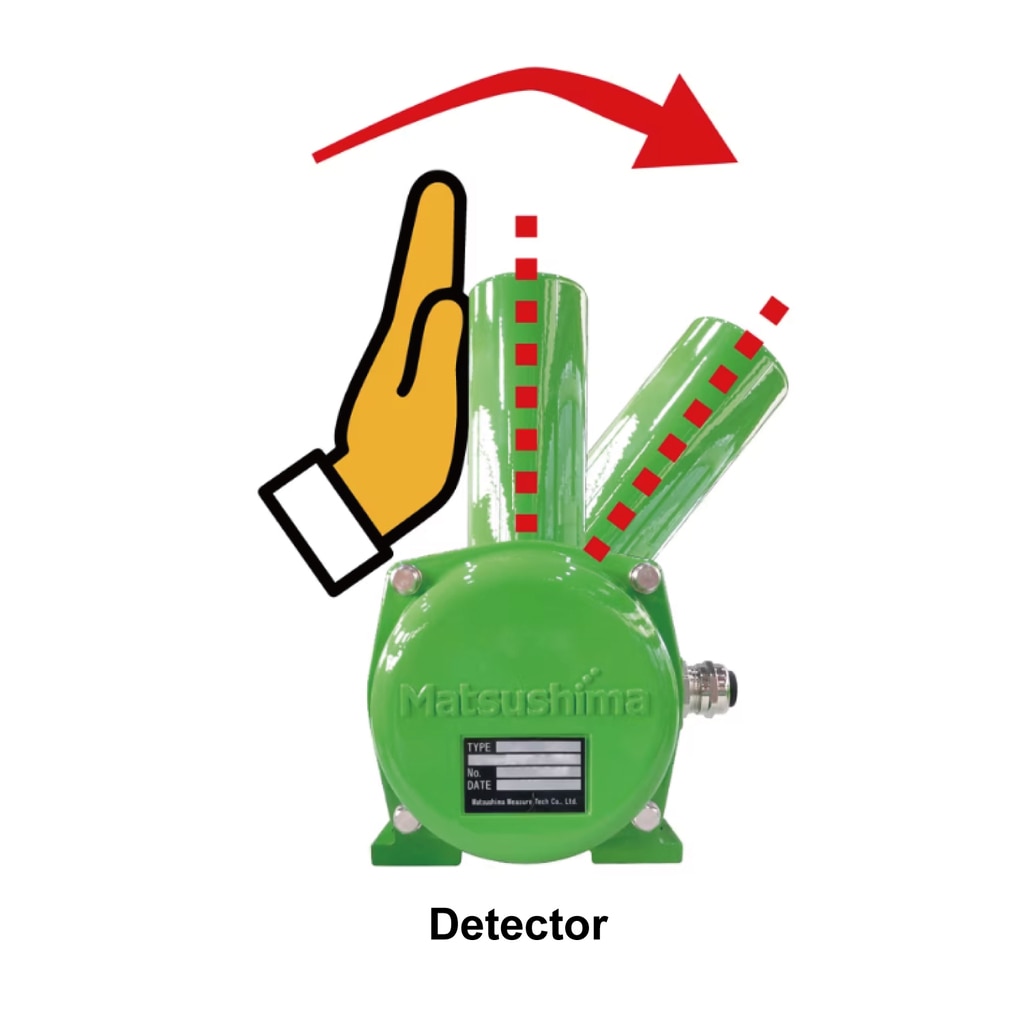

When the detector's touch pulley detects belt misalighment, the built-in potentiometer sends a signal to the electric actuator according to the angle.

In addition, even if the detector stops detecting misalighment, the adjustment carrier keeps rotating until the detector on the opposite side detects misalighment, ensuring correct misalighment.

How to use?

1.Determine

mounting position

Install in a place where misalighment occurs. However, avoid places where belt is constantly wet or where the conveyed material is attached, places where the belt speed is 250m/min or more, places where the end surface of belt is damaged and uneven.

2. Mounting

Install the detector at least 1m away from the electric actuator so that the detector can detect misalighment before the electric actuator. Since the electric actuator is heavy, use a chain block or the like to insert it into the conveyor. Considering the turning range of the alignment carrier, install it so that it does not interfere with existing rollers and conveyor frames.

3. Wiring

Connect the two detectors to the electric actuator and wire the power supply to the electric actuator. For reversible conveyors, wire the reversible relay box as well.

4. Adjustment

Adjust the position of the detector and the belt, and the gap between the alignment carrier roller and the belt.

Also, operate the touch pulley by hand to confirm that the alignment carrier turns in the correct direction.

*For details, please refer to the instruction manual.

\ Download or Request for quote /

Maintenance

Inspect and clean as follows once every three months.

- If a conveyed object adheres to the revolving or rotating parts, it will hinder rotation and cause malfunctions, so check this carefully.

- Carrier rollers and touch pulleys come into contact with the belt and wear out .

- Tilt the detector's touch pulley by hand and confirm that the alignment carrier turns.

Model lineup

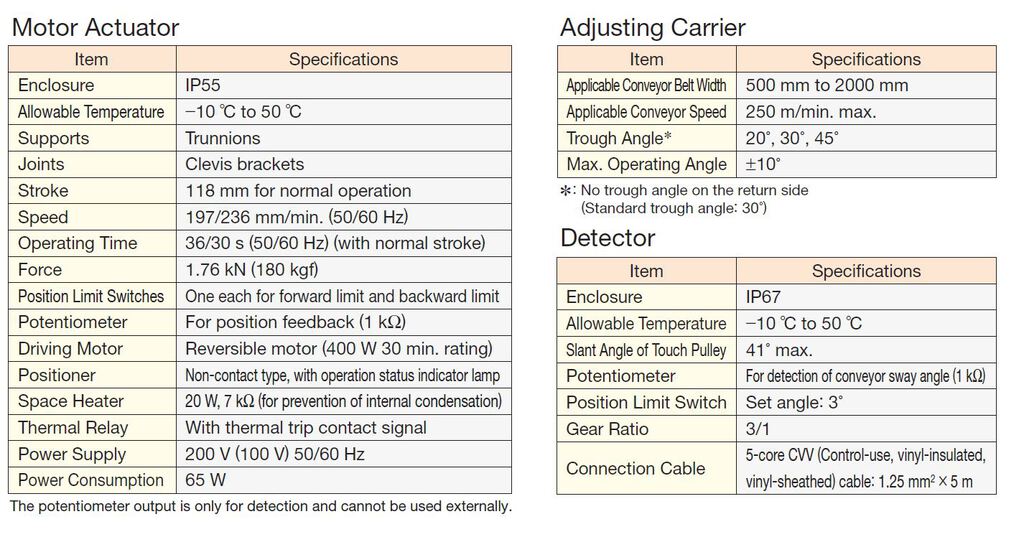

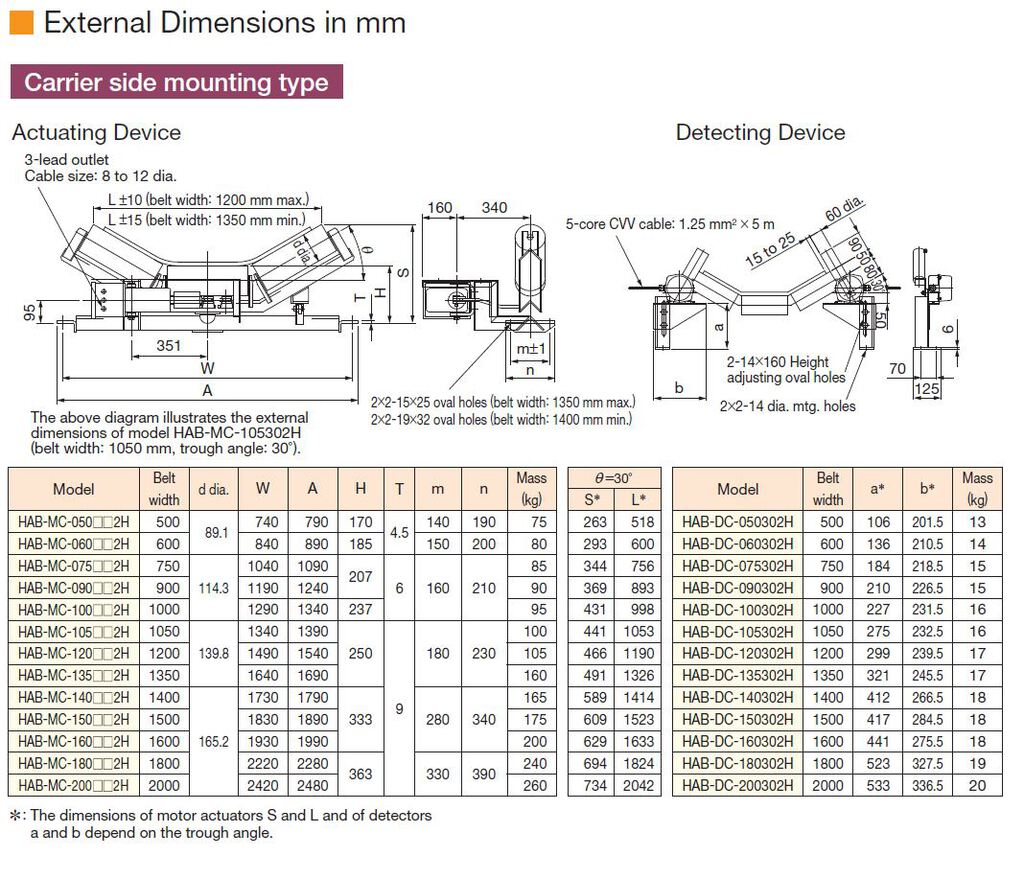

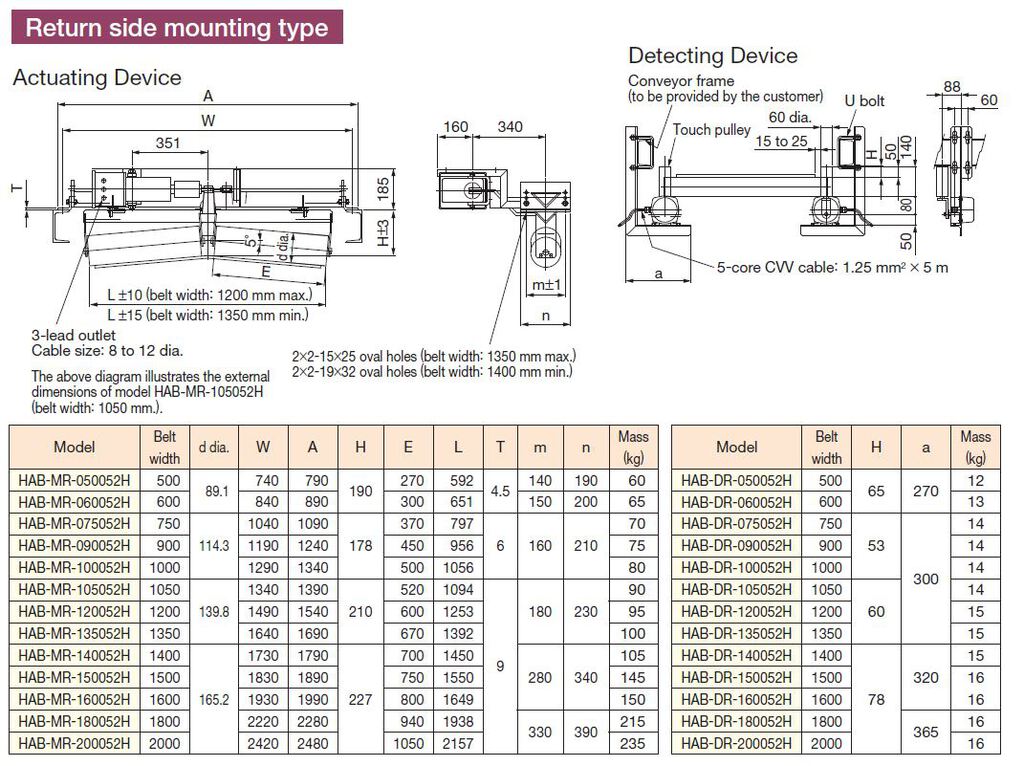

Specifications

\ Download or Request for quote /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.