Radar solves worries of Sounding Level Transmitter

Issues on level measurement at production sites

Typical problems or worries asked for consultation are;

Contact type level transmitters may get damaged especially at portions where contact with the process in the long term use, and then may raise the risk of facility damage and foreign matter contamination.

● Expensive cost for adjustment and maintenance of the equipment

Periodical maintenance or replacement of consumable parts are required in case of contact type level transmitters (or the one which has mechanical movable portion).

● It may cause malfunction (wrong measurement)

Ultrasonic level transmitter (or the one which uses air as emitting media) may cause malfunction (wrong measurement) according to conditions (vapor, dusty, etc.) in the silo or tank.

Solved by Radar Level Transmitter!

| Worries | Why can Radar Level Transmitter solve? | |

|

Worry about facility damage due to drop of the sensing weight by wire-rope cut |

⇒ |

No worry of wire-rope cut or sensing weight drop because it's non-contact measurement principle and there is no mechanical movable portion. |

| Expensive cost for adjustment and maintenance of the equipment | ⇒ |

Required maintenance is cleaning of horn antenna only. |

| It may cause malfunction (wrong measurement) | ⇒ |

Radar is electromagnetic wave and no influence from air conditions (temp, pressure, etc.) besides it's possible to go through vapor or flying dust because of it's permiability. |

Featured functions

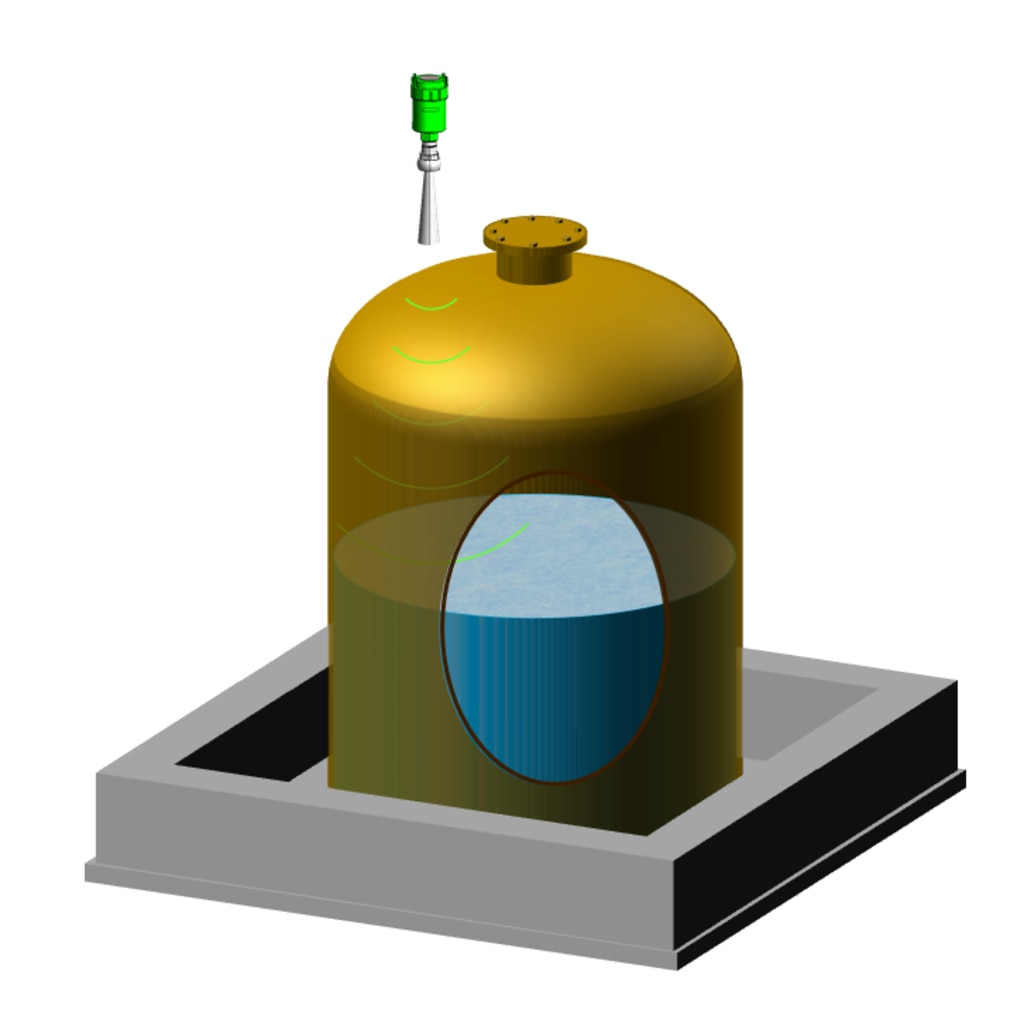

Measurement through the tank

Measurement through the tank is possible because of electromagnetic wave characteristic. It's useful for corrosive gas conditions.

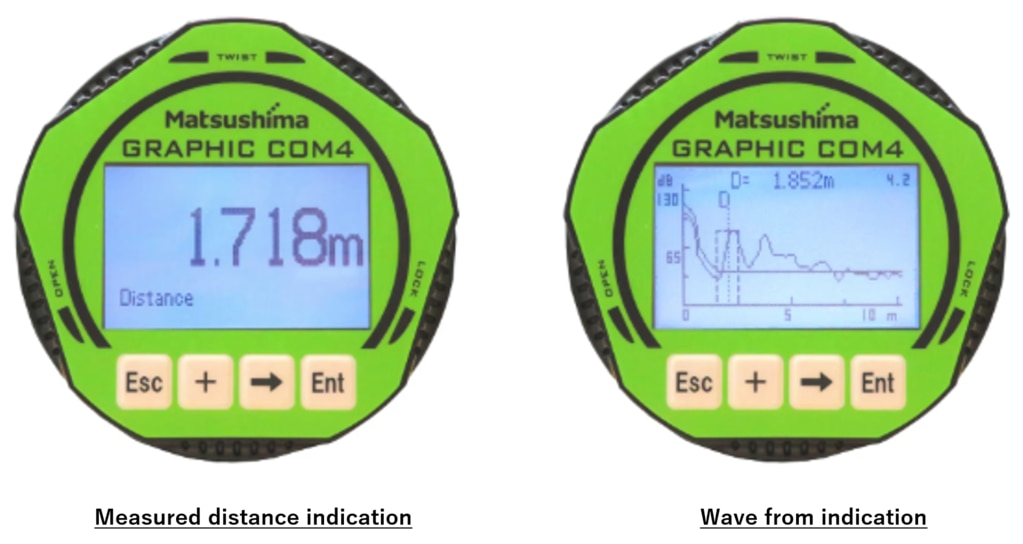

Handheld adjustment unit

Parameter setting and wave form observation is possible with the handheld adjustment unit (GRAPHIC COM) other than adjustment PC.

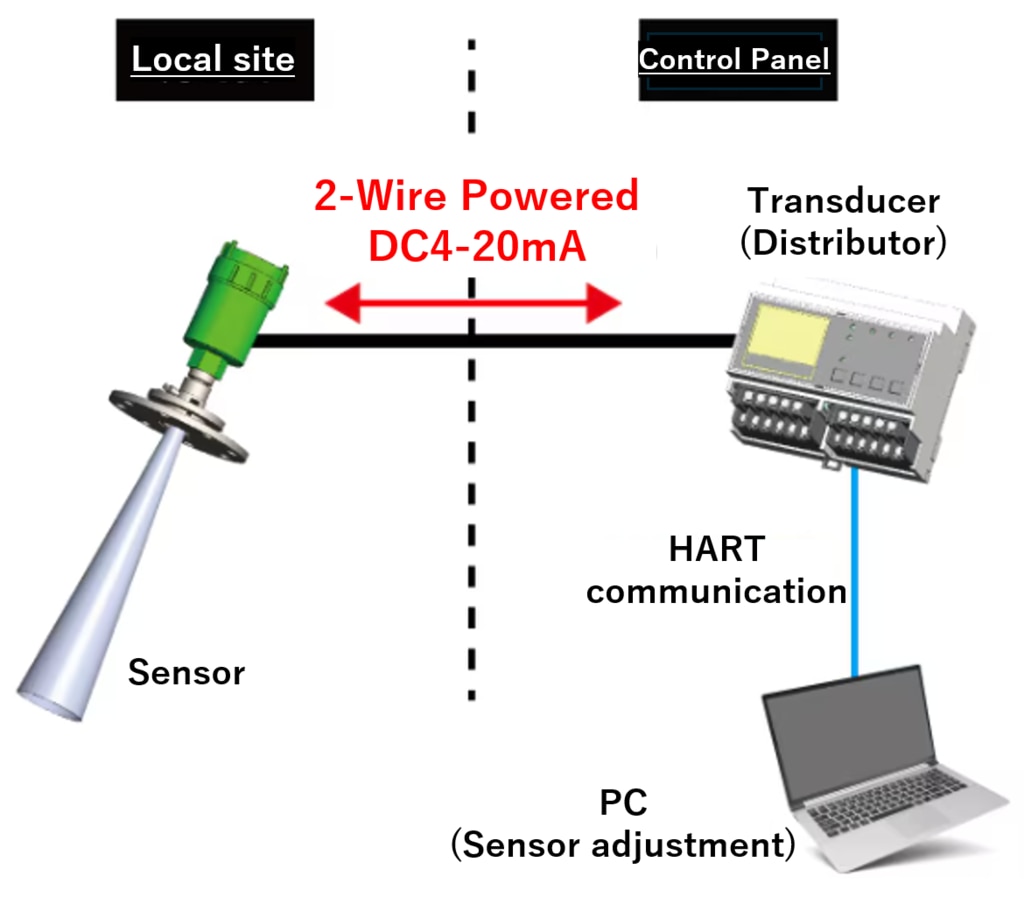

HART communication

Compatible with HART adjustment equipment.

Benefits

Productivity improvements

Productivity improvement is expected because it can reduce down time, troubles or maitenance time due to malfunction (wrong measurement) and stable plant operation is possible.

Cost reduction

Uneccessary cost for supervising, parts replacement or unwanted maintenace work can be reudced.

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.