Electric Arc Furnace

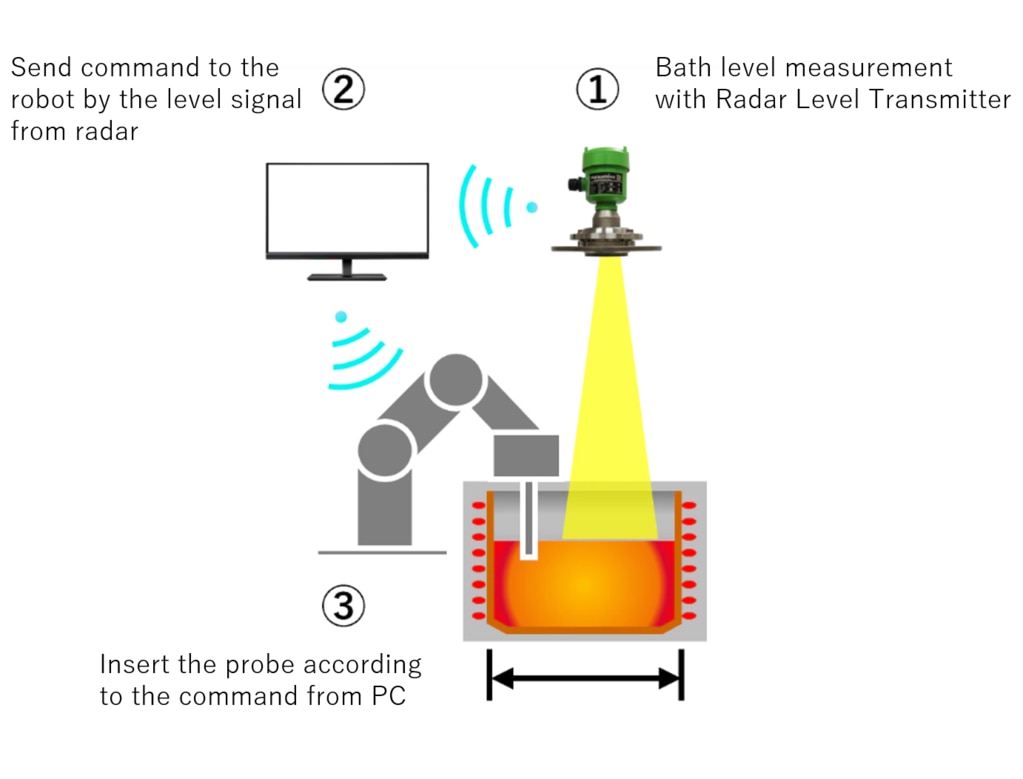

Automating bath level measurement in electric arc furnaces is a revolutionary technology that significantly improves the efficiency and safety of the steelmaking process. Advanced solution like "Matsushima Measure Tech EAF Bath Level Measurement system with Radar" enable accurate measurements even during arc flashes, providing essential real-time data for controlling and optimizing furnace operations.

Overview of Electric Arc Furnaces

The Electric Arc Furnace (EAF) is an innovative steelmaking technology that uses high voltage electric current to melt and refine metals, especially steel. Starting from raw material, mainly scrap iron, the EAF efficiently melts the metal using an electric arc that generates high temperatures of over 3000°C.

The main advantages of the EAF are:

- Compared to the conventional blast furnace method, CO2 emissions are significantly reduced, reducing the environmental impact

- Electricity is the main energy source , making it possible to use renewable energy

- Promoting the recycling of scrap iron and contributing to the effective use of resources

- Flexible production scale adjustment allows for quick response to market demand

- By combining with the latest control technology , we can produce high-quality steel products

As the core of sustainable steelmaking processes, EAFs make a significant contribution to making the steel industry greener and more efficient.

Electric Arc Furnace working environment

The working environment of an electric arc furnace involves many hazards, including high temperatures, harmful dust and the risk of explosion.

To ensure your safety, it is important to take the following precautions:

- Wear appropriate protective gear (heat-resistant clothing, helmet, dust mask)

- Elimination of harmful substances through the implementation of effective dust control systems

- Water-cooled panels prevent furnace overheating and protect workers

- Strict raw material inspection and moisture control to reduce explosion risk

- Installing a carbon monoxide concentration monitoring and alarm system

- Develop clear work procedures that define safe worker positioning

These measures ensure the safety of workers and ensure efficient operation. Compliance with environmental regulations and maintaining a safe working environment are also important issues for electric arc furnace operators.

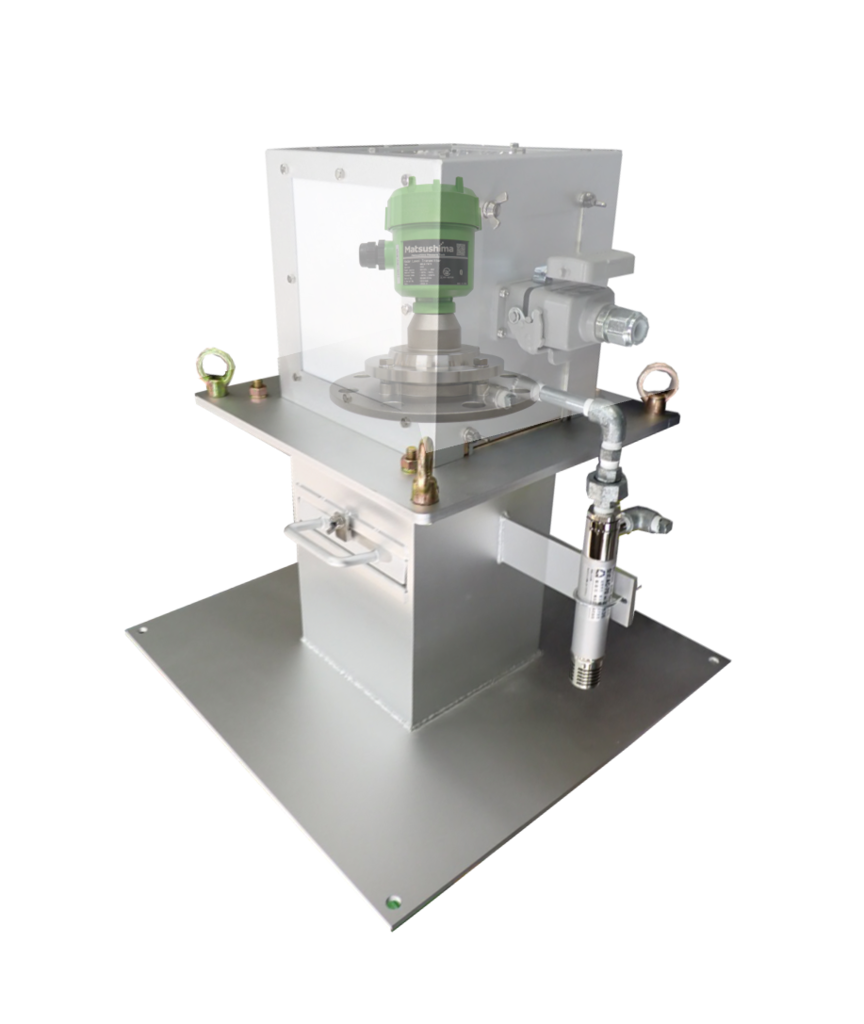

EAF Bath Level Measurement with Radar

Bath level measurement in electric arc furnaces using radar level transmitters is a highly accurate and reliable non-contact measurement method.

The technology has the following features:

- Uses 80GHz frequency modulated continuous wave (FMCW) radar to achieve high accuracy of ±5mm with a measurement range of up to 30m

- Stable measurement is possible even in harsh environments such as high temperature, high pressure, and steam

- Accurate metal bath level detection without being affected by slag thanks to reflection from the metal surface

- Measurements can be made even during arc discharge, allowing real-time understanding of furnace operating conditions

- This technology enables efficient operation management of electric arc furnaces, contributing to improved productivity and safety, and by transmitting measurement data to a process computer, it can also be used to optimize raw material input and reduce fuel costs.

Product Information

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.