Level Transmitter・Level Switch <Liquid>

Conductive Level Switch is level sensor for detecting level of liquid. When electrode comes into contact with liquid, electrical circuit closes and switch operates.

Please use it for control, alarm, etc.

Advantages

- Achieves multi-contact detection at low cost.

-

Since there are no moving parts, it can be used stably for a long period of time.

-

By cutting electrode part, detection position can be changed freely by the customer.

-

It can be used with various liquids by changing material of electrode part.

\ Download or Request for quote /

Features of Conductive Level Switch

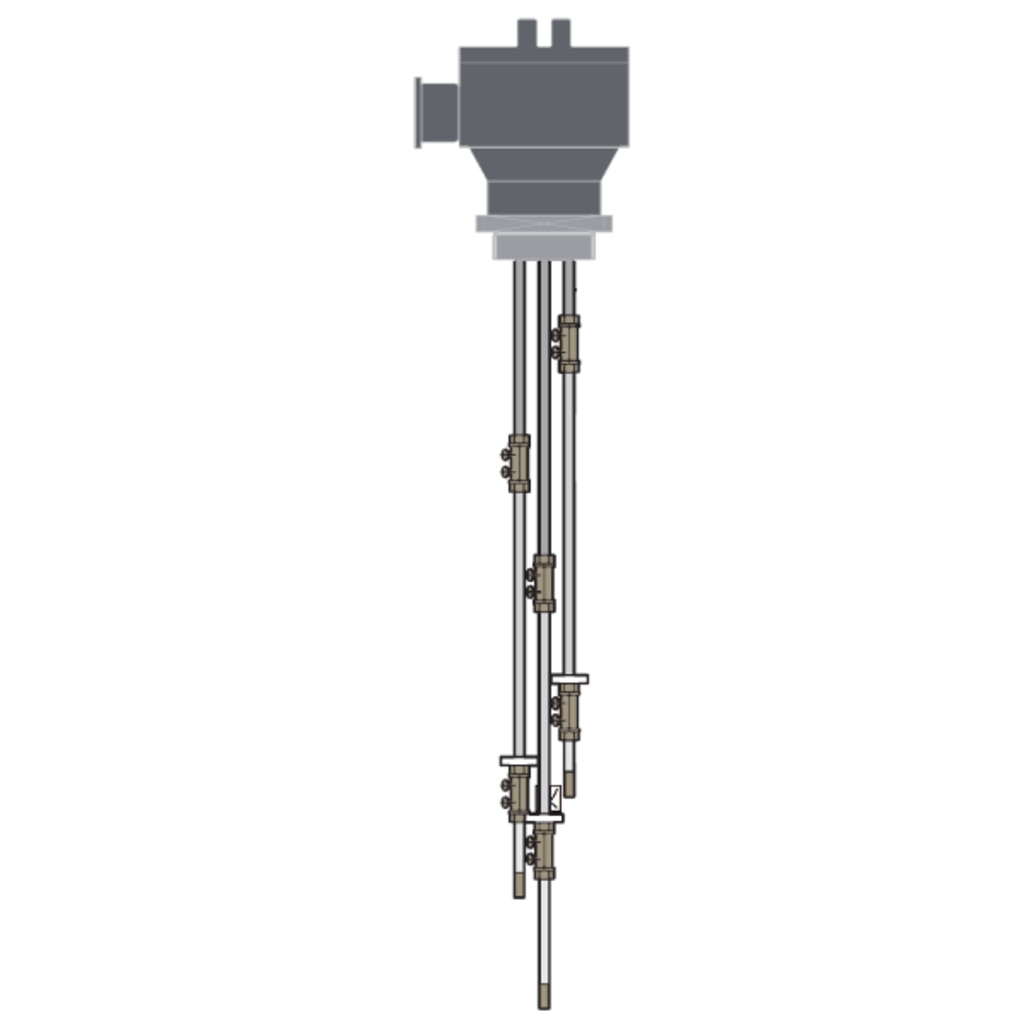

Detect up to 6 points

with one device!

One level switch can output up to 6 points of contact, making it possible to construct level measurements at low cost.

Compatible with

various liquids

By changing material of electrode part, it can be used with various liquids.

Structure resistant to

steam inside tank

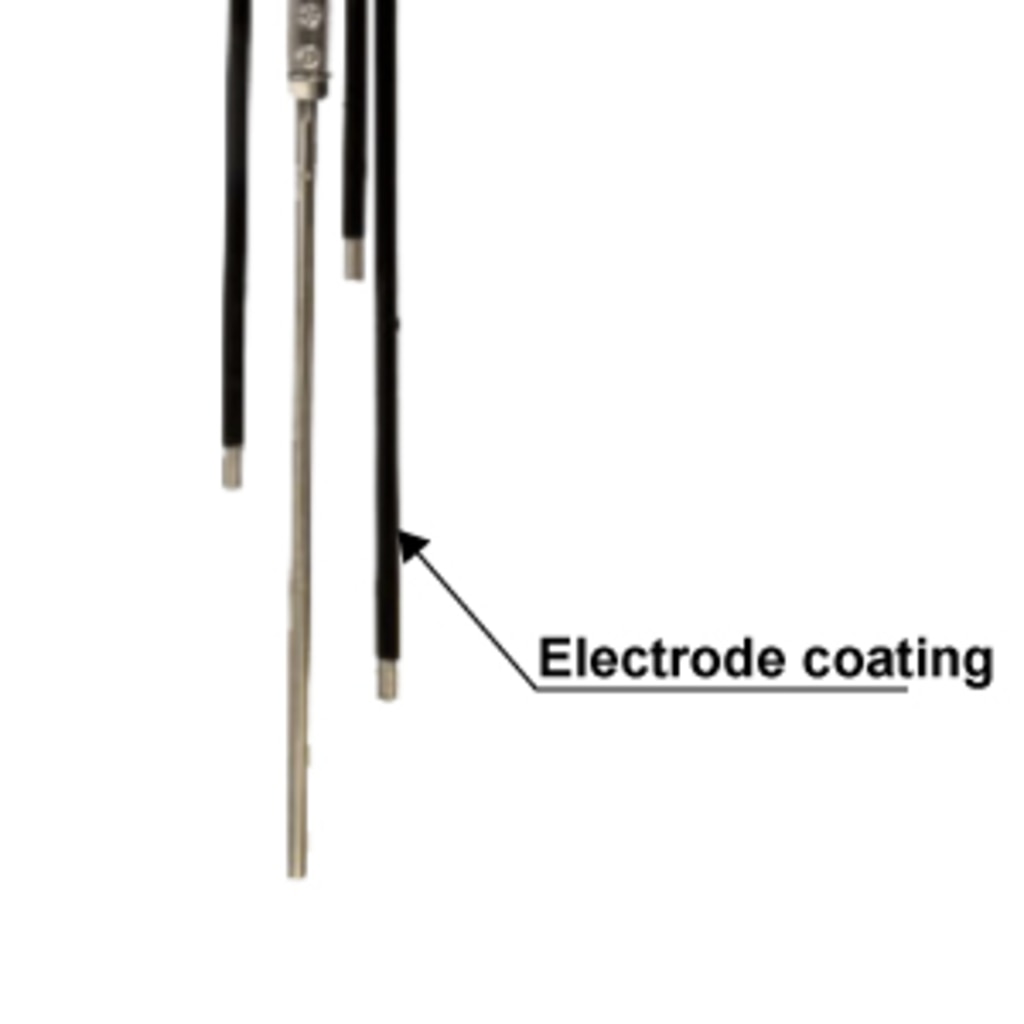

By covering area other than electrode at tip, there will be no malfunction even if floating objects come into contact with it.

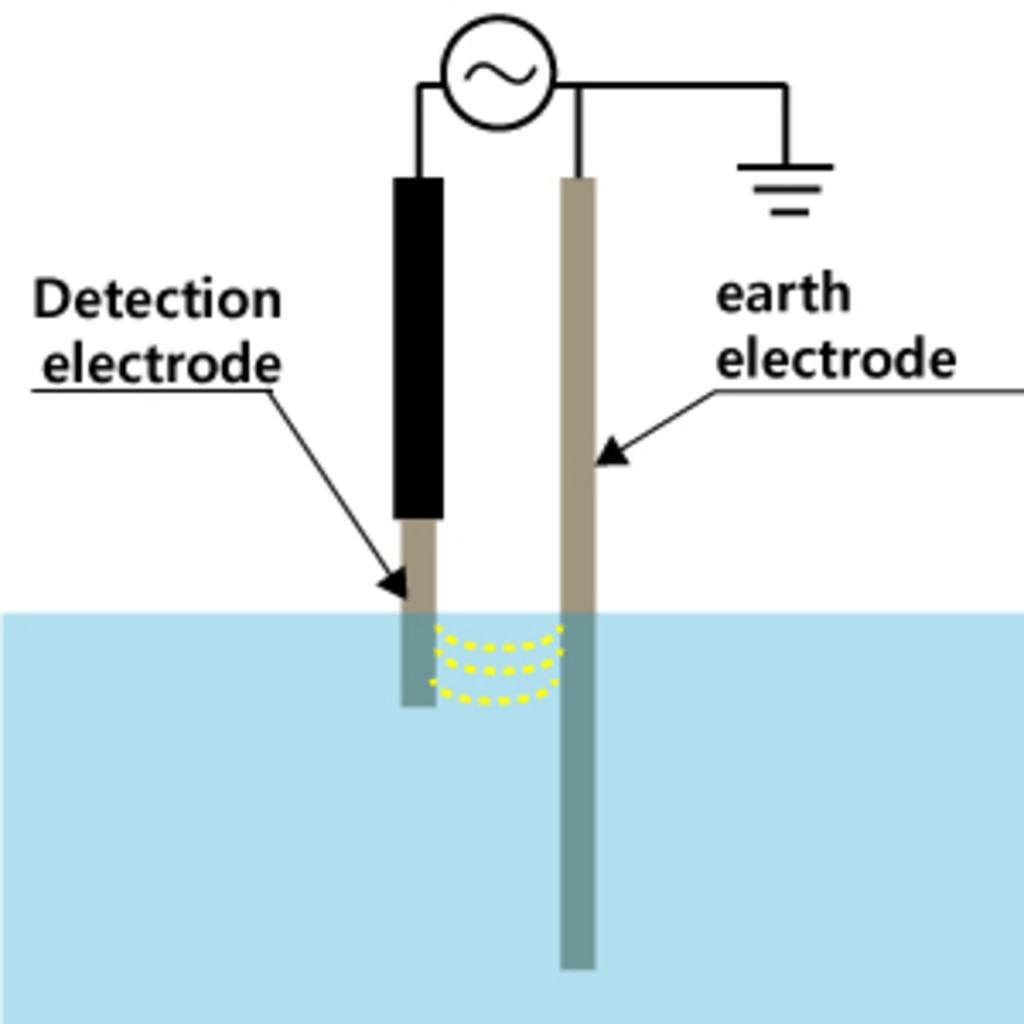

Operating principle

Conductive Level Switch are used in combination with relay units. The relay unit supplies a weak alternating current, so if surface of conductive liquid is not in contact with electrode rod, no current will flow to electrode, and when electrode rod touches liquid surface, current will not flow. It flows.

When current flows, the relay contacts open and close, informing you of detected and undetected areas.

How to use?

1. Installation

Install electrode level switch vertically.

2. Electrode

connection

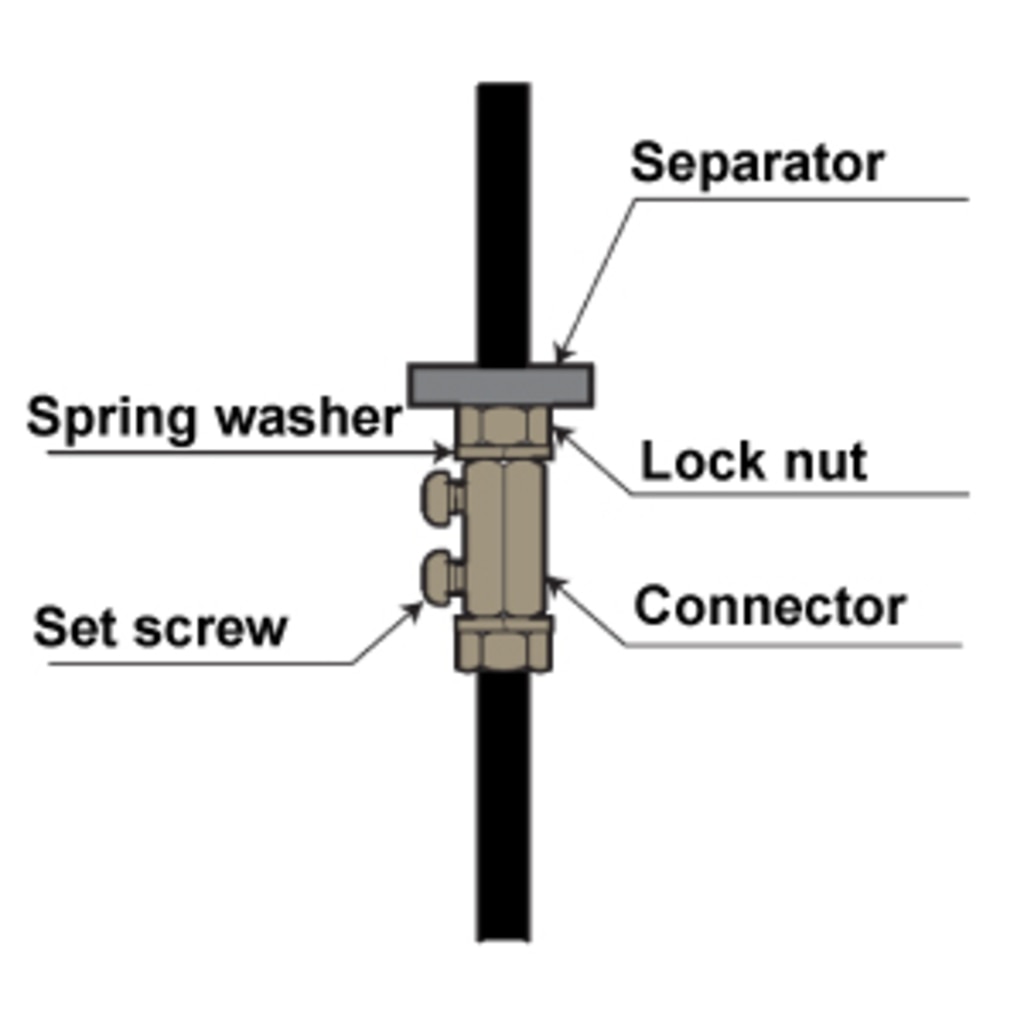

1. Pass separator (if electrode rod is over 1m), lock nut, and spring washer in this order.

2. Loosen the set screw on the connector, screw the electrode rod into the center of the connector, and tighten the set screw again to secure it.

3. After fixing, tighten the lock nut to prevent it from falling off.

3. Ensuring

continuity

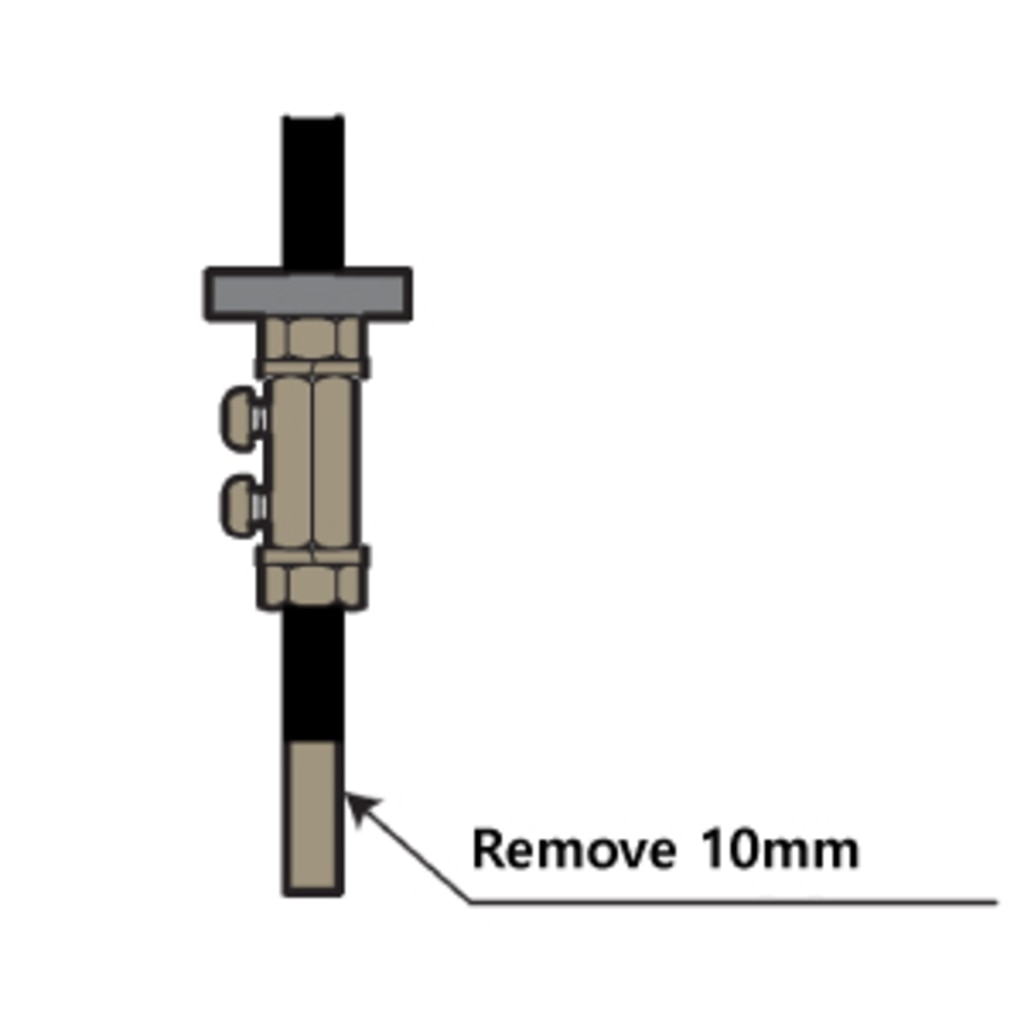

When cutting the electrode rod to match the control level,

remove 10mm of the coating from the tip to ensure continuity. (Above figure) (excluding ground electrode)

4. Wiring

Please use electric wires of approximately 1.25sq. Use M3 screws with a pitch of 7 mm between terminals and crimp terminals.

*Regarding relay unit, please prepare

a product with current protection separately . (Recommended product: OMRON 61F series)

*Please see the instruction manual for details.

\ Download or Request for quote /

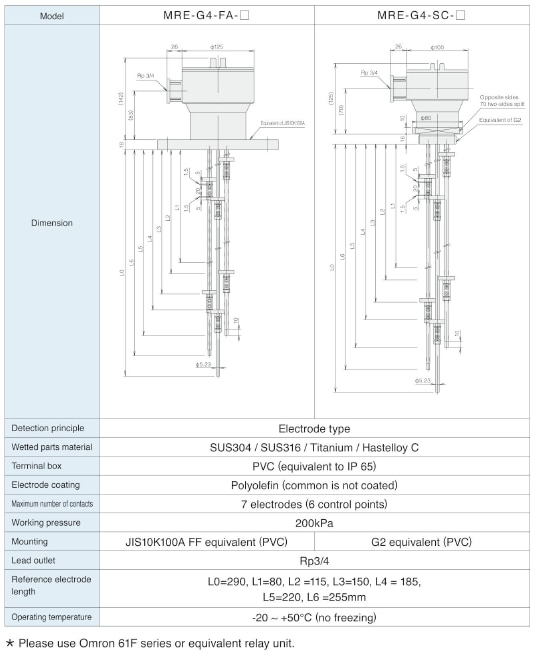

Model lineup

●MRE Series

Specifications/Dimensions

\ Download or Request for quote /

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.