Cathode material cost saving in the secondary battery manufacturing process

An issue in the secondary battery manufacturing process

Seconcary battery (often called Rechargeable battery) can be repeatedly used because it's rechargeable.

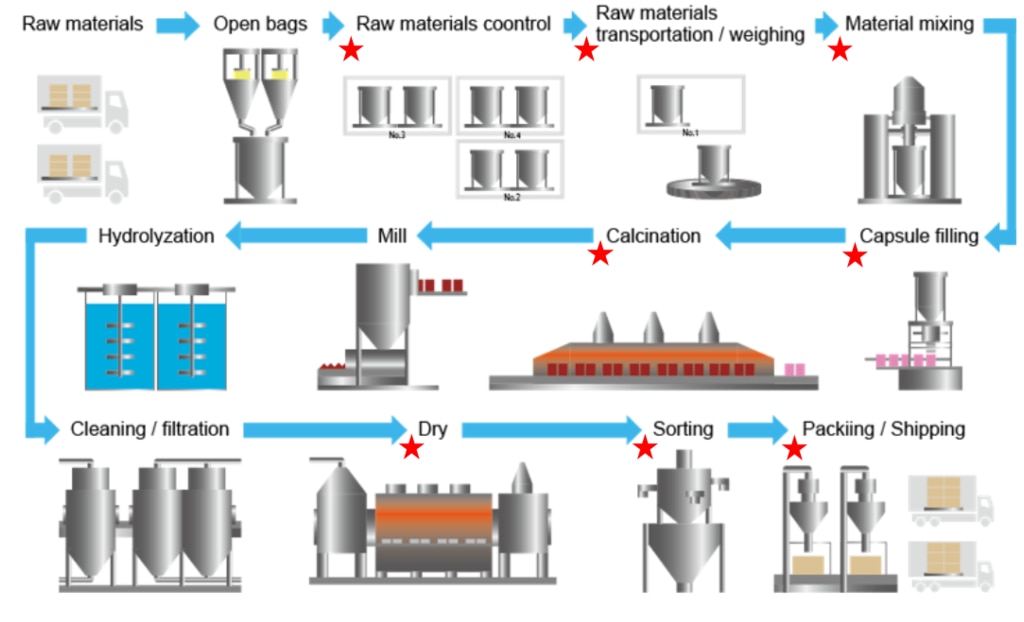

One of the leading cathode material producers for secondary batteries, who has a lot of factories around the world, installs approximately 40 dust collectors in each factory to collect and reuse raw materials because those raw materials for the process are expensive and valuable.

However, the company used to hold a problem of raw materials leakage from the process due to deterioration of dust collectors or insufficient maintenance.

This raw materials loss was about US$200,000 per every month.

Furthermore, it was also concerned about the problem of air polution.

As a result, large losses due to leakage of expensive and valuable raw materials had become an issue.

Important issue is how we can save the losses due to dust leakage.

The dust monitor continuously monitors the exhaust from the dust collector and solves the problem!

By installing a dust monitor in the exhaust duct of a dust collector, it is possible to detect dust leaks from the dust collector at a minute level and predict signs of dust leakage.

Benefits

Prevent damages before it happens

Possible to take measures beforehand and so prevent such damages before it happens.

No losses due to leakage

Loss reduction realized because of no raw material leakage from the dust collector.

Easy maintenance of the facility

No periodical replacement of filter required.

Cleaning work after leakage is drastically reduced.

Reference articles

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.