Dust Monitor Applications

There are many places where require dust collectors as environmental countermeasures because the production process of steel industry is harsh and generating a lot of dust.

However, despite those countermeasures, it sometimes causes dust leakage due to facility deterioration or inadequate maintenance of machineries and then it causes huge loss in time and cost to recover the facility.

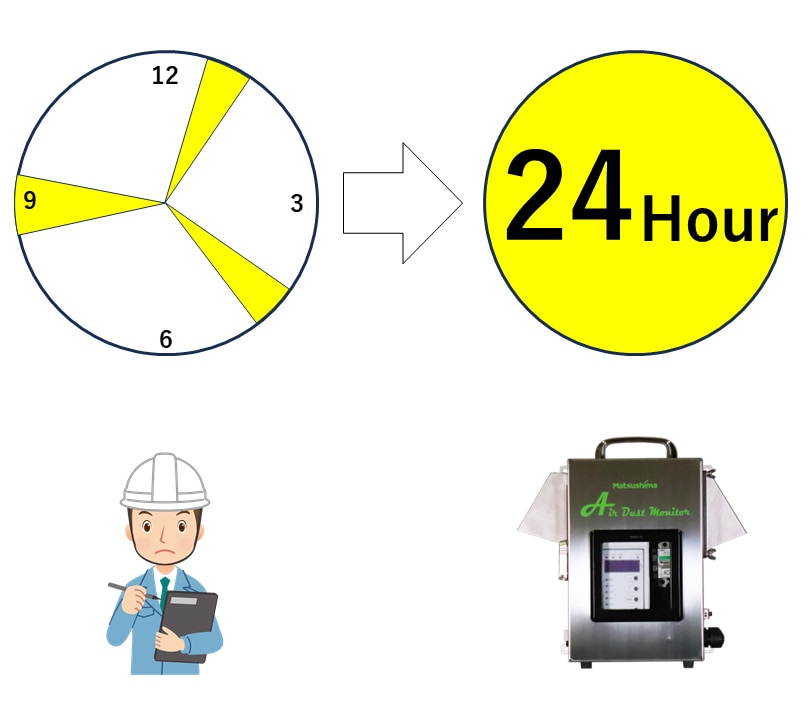

Recently it is recognized that predictive maintenance by continuous monitoring of dust amount is effective to take countermeasure before it causes serious dust leakage.

PFM Series Matsushima Measure Tech Dust Montior provides such 24 hours continous monitoring of dust concentration and contributes to predictive maitenance.

Please refere to the following successful references.

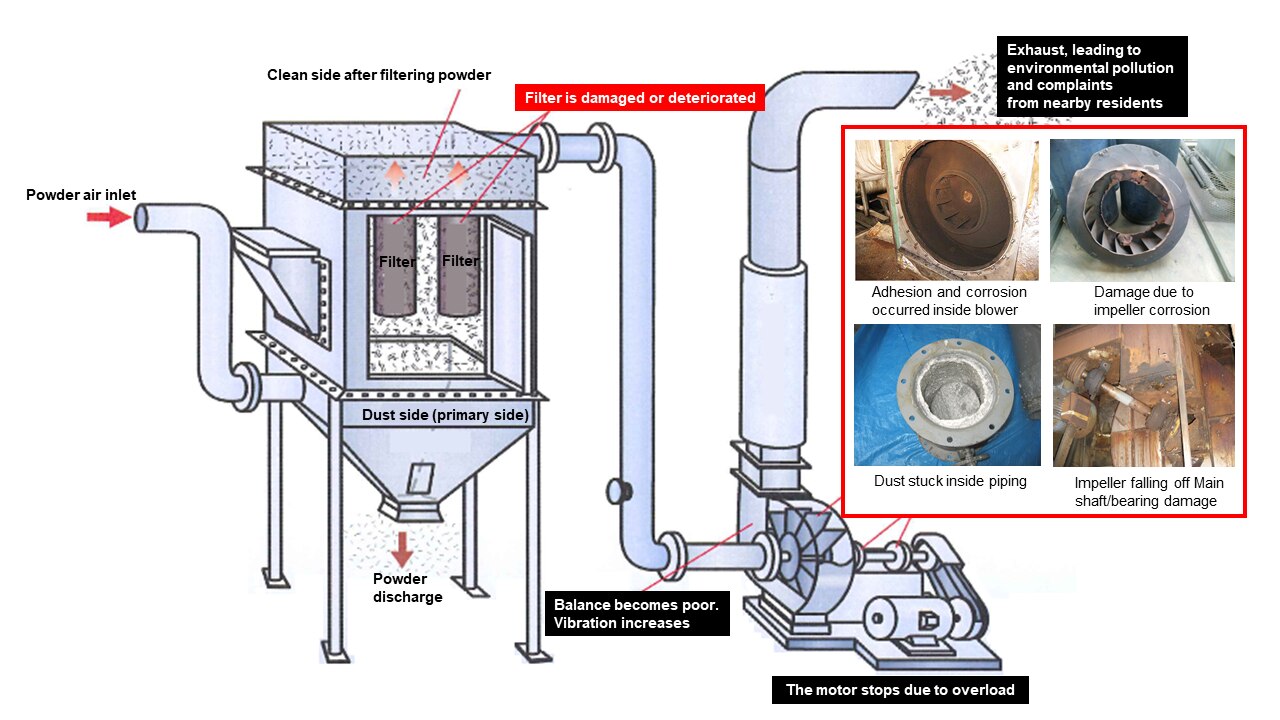

If filter bag of dust collector is damaged...

Genrally filtered clean air comes in the secondary piping side, however, leaked dust may come there in case filter bag is deteriorated.

This situation may get damaged the blower and bring the risk of overload at the motor as well as leading to environment pollution or clain from local residents.

In the worst case, such filter bag breakage leads to facility shutdown.

Economic benefits by monitoring dusk leaks

1. Labor saving

Realize predictive maintenance by continuous monitoring 24 hours a day instead of a human. Reduce maintenance work load.

2. Cost reduction

Maintenance costs are saved since filter can be used up to the end.

No periodical replacement (filter bag) required.

3. Energy saving

Energy saving effect expected in case dust collector is controlled according to dust concentration.

Reference applications of Dust Monitor

Dust Monitors are used at various sites in steelworks. The main examples are as follows.

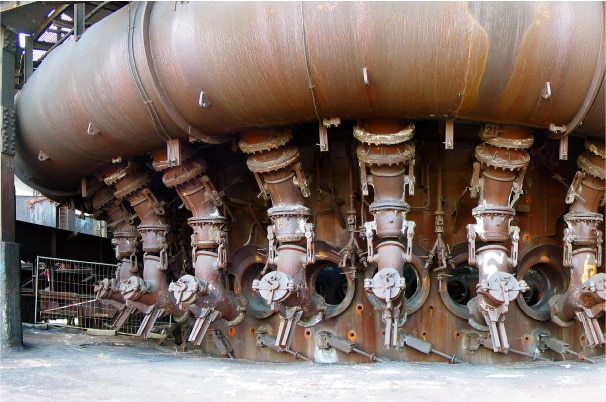

1. Sintering plant

2. PCI facility

3. Coke plant

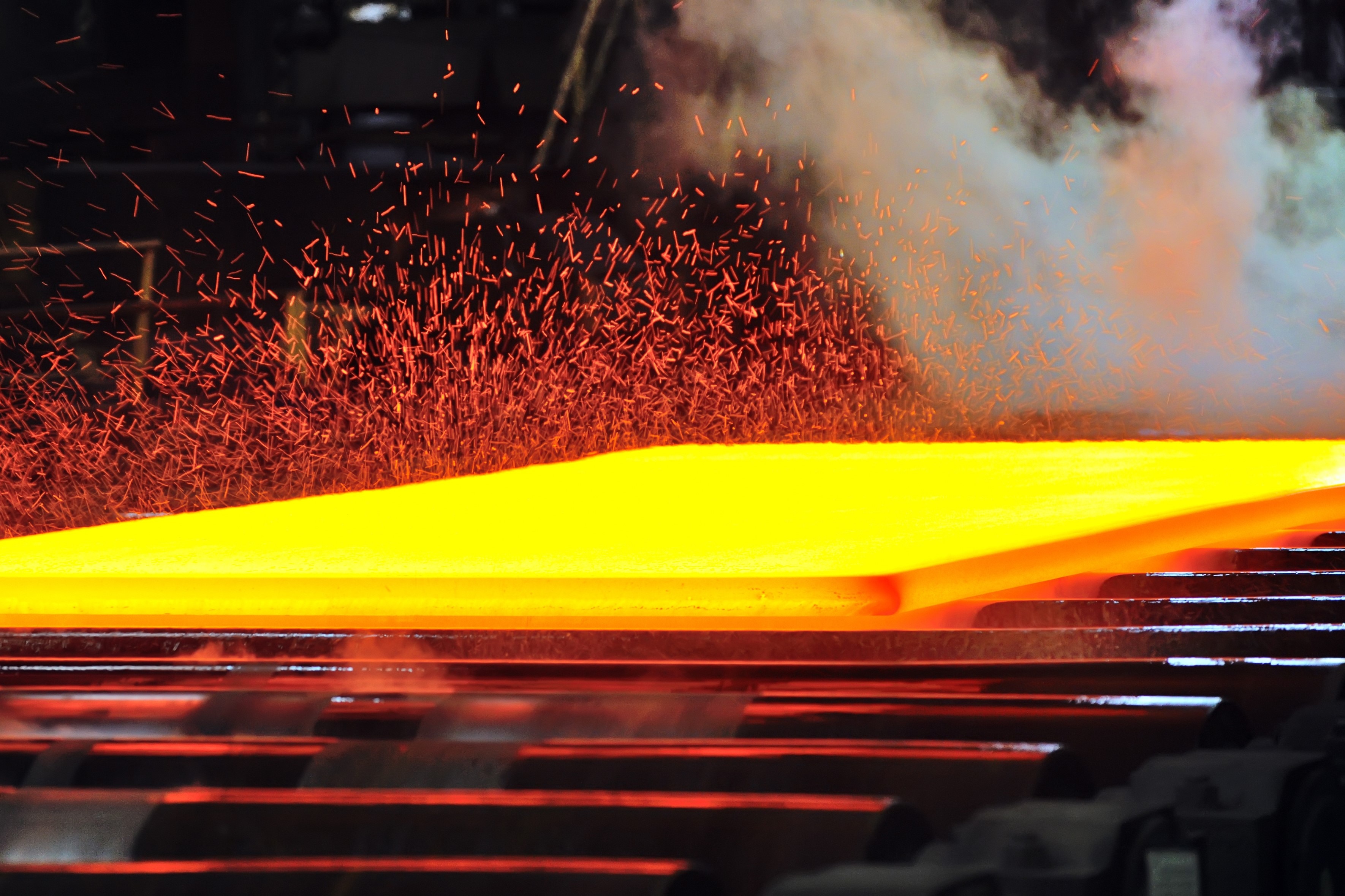

4.Hot rolling mill

5.Converter plant

6. Electric furnace

7. Coal handling

8. Fly ash

9. Welding fume

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.