Dust Collector Running Cost Reduction

Problems at the site

Furthermore, because location of the leak inside the dust collector could not be identified, all filters (filter cloths) were replaced .

Due to this situation, they were worried that they wanted to improve the working environment as much as possible and reduce the need for unnecessary filter replacements.

1. Worries difficult to know when dust will leak out

2. Want to use up all filters bags

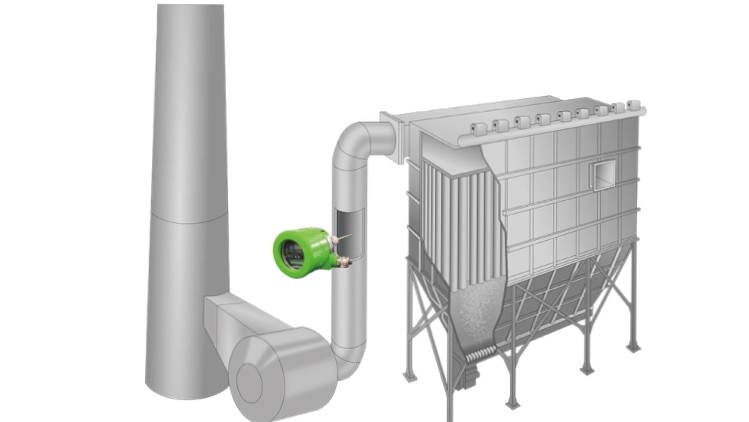

Triboelectric Dust Monitor solves them!

Triboelectric Dust Monitor provides realtime continuous monitoring for dust concentration and detect dust leakage immediately when it happens.

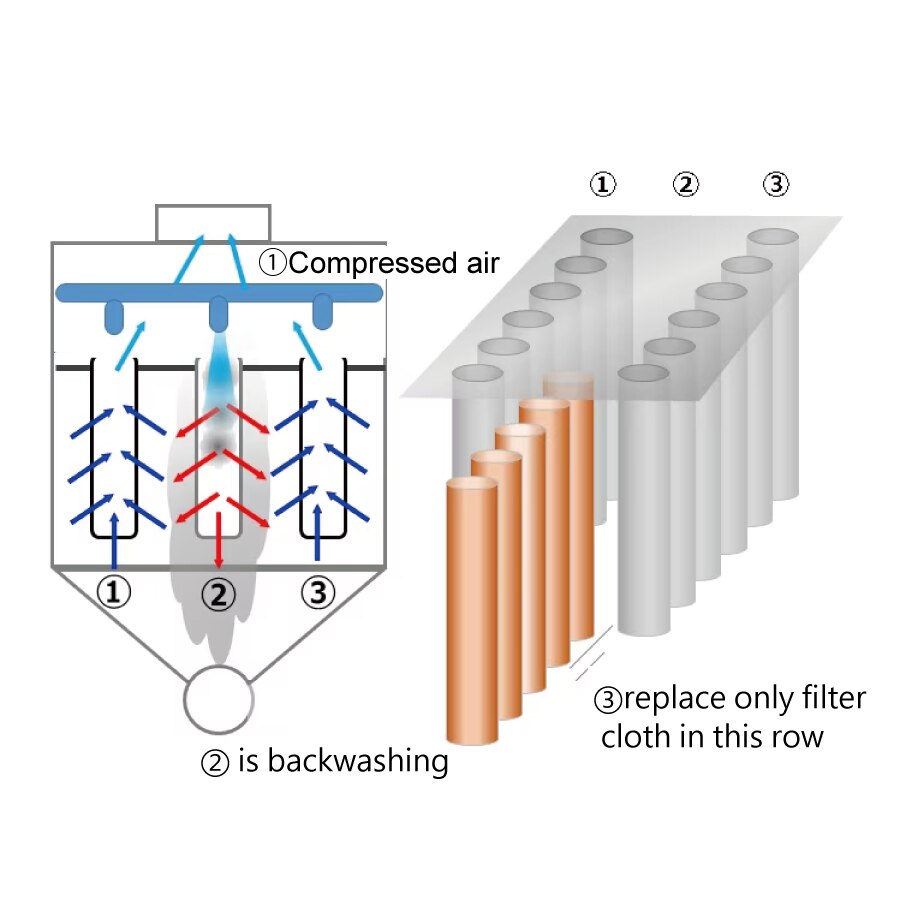

It detects even small amount of dust leaking out from small crack of filter bag and it's possble to identify damaged filter bags where the signal of Dust Monitor and backwash pulse timing is synchronized.

Finally, it is possible to realize running cost because those filter bag can be used at the end of lifetime as predictive maintenance.

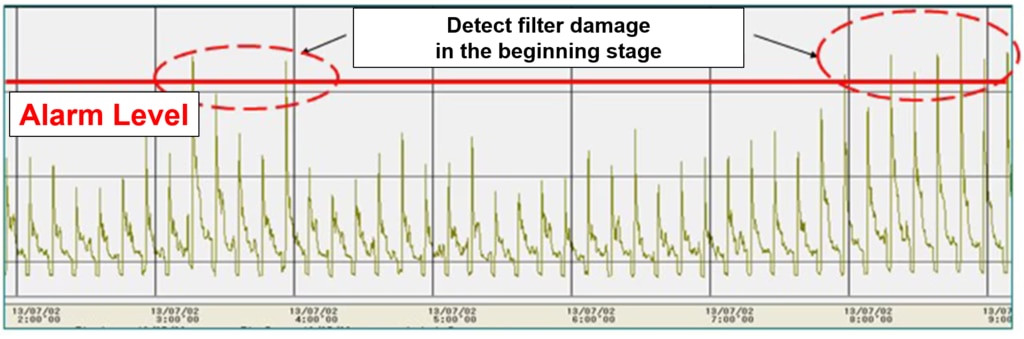

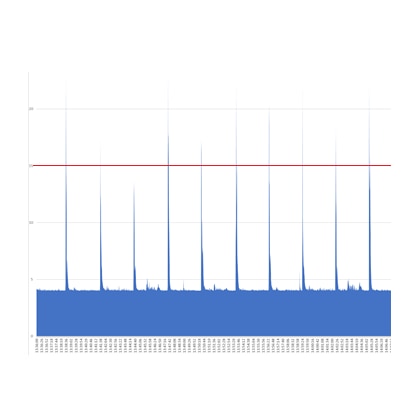

It is possible to observe dust leakage trend by recoding concentration signal output (DC4-20mA) from Dust Monitor.

* Above trend chart is dust concentration signal when backwash pulse is applied.

Featured Functions

24H continuous monitoring

Continuous measurement (0.1-1000mg/cbm) in place of human observation. Alart output before regulated value. Running cost reductoin possible as filter bags can be used until the end of lifetime.

Approximation vaule to absolute measurement

Dust concentration compensation (approximation) function mode available. Aproximated value compensated by input factor can be output. (Compensation factor adjustable from 0.1 to 2.0)

Complied with JIS standard

Matsushima Measure Tech Triboelectric Dust Monitor is automatic measurement instrument complied with JIS standard (JISB7996). Correction coefficient is quite high (0.969) and almost replaceable with isokinetic measurement system.

Benefits

Labor saving

Use filter bags up to the end of lifetime

Running cost reduction

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.