Monitoring dust in ducts

Major causes of deodorizer failure

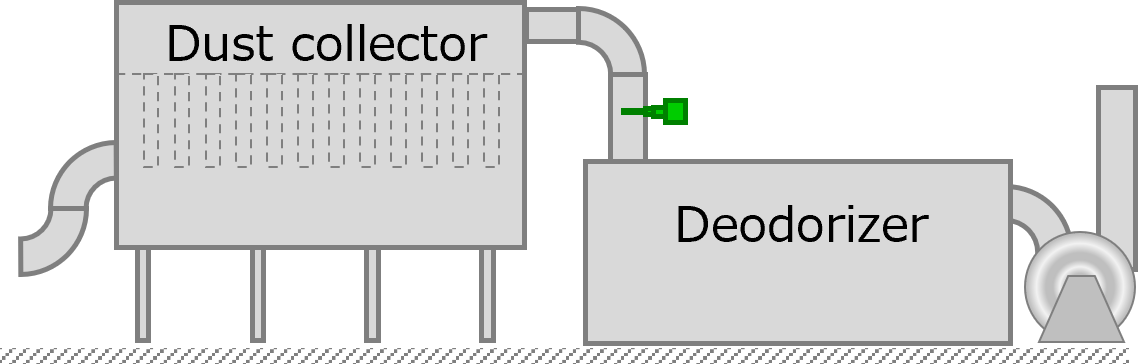

One of the causes of deodorizer failure is dust leakage from dust collector.

When leaked dust adheres to components and mechanisms inside deodorizers, the viscous and chemical properties of the dust, which are microscopic particles, can interfere with the operation of the deodorizer. For example, dust could cover the absorbent material or catalyst in the deodorizer, reducing its effectiveness.

And many factors that cause dust to leak from dust collectors are due to bag filter deterioration or inadequate installation (maintenance errors).

Background of Introduction

At a certain factory, malfunctions of deodorizer occurred frequently. The main cause was dust leakage due to incorrect installation of dust collector bag filter or deterioration of the filter.

Therefore, for predictive maintenance of deodorizer, a dust meter was required to be installed to constantly monitor condition of dust collector filter and dust leakage.

Dust monitor is

the solution!

Visualization of

trace dust leaks

The dust monitor is installed between the dust collector and the deodorizer to constantly monitor dust leakage from the dust collector with a high sensitivity of 0.1 mg/㎥ for 24 hours.

Only three settings are required for adjustment: range, and integration time, alarm time.

Decisive factor for

introduction

Low cost and easy

maintenance

- 24-hour monitoring.

- Compared to other methods of optical dust meters, initial cost is low and easy to introduce.

- Low running cost and easy to maintain.

- Easy to adjust and maintain.

Effects after

introduction

Almost no dust

leakage!

Dust leakage from the dust collector can be detected and foreseen from the minute amount stage, allowing action to be taken before damage occurs.

This eliminates the burden on deodorizers and dramatically reduces breakdowns.

Dust Monitor

Dust Monitor is a dust indicator (dust concentration meter) specialized for monitoring dust emissions from dust collectors.

It detects the beginning of dust leakage, leading to not only predictive maintenance (predictive maintenance) but also labor and cost savings.

Related Articles

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.