Avoiding risk of dust

What is dust explosions?

Dust explosion is a phenomenon in which a space is filled with flammable dust above a certain concentration, which ignites and explodes if there is a spark. The power of such an explosion is tremendous, causing buildings to collapse and many people to be injured in an instant.

Factories that manufacture a variety of products often use powder as a raw material, and dust tends to fly around. In addition, various electrical equipment and fluorescent lights are installed in the surrounding area, which can become a spark for a fire.

Take a flour mill for example.

Flour is sent to tank by pneumatic conveying. Therefore, top of the tank is filled with highly concentrated flour dust. If a fluorescent light that was lit here breaks in some way, the fluorescent light could spark a fire and cause a dust explosion.

You may be thinking, "How can flour cause an explosion?" However, even a small amount of flour ignited by a dust explosion can cause a chain of ignition in an instant because of the high concentration of dust in the surrounding area. In other words, this instantaneous chain of ignition is an explosion.

Other coal-fired power plants also have a risk of explosions due to the dust and coal powder in the buildings, and countermeasures are in place to prevent such explosions.

Background and Issues

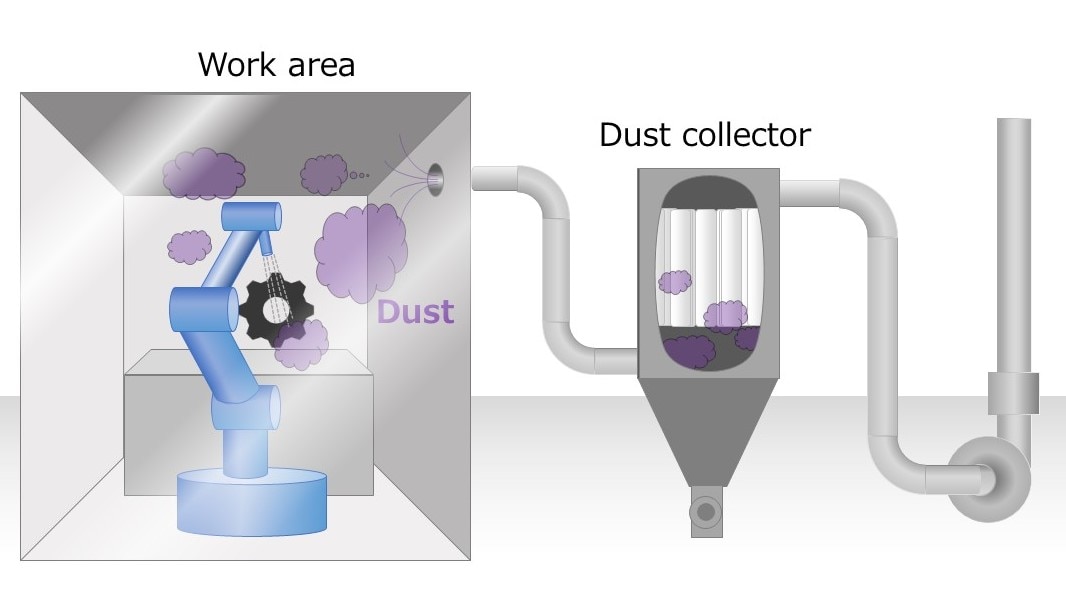

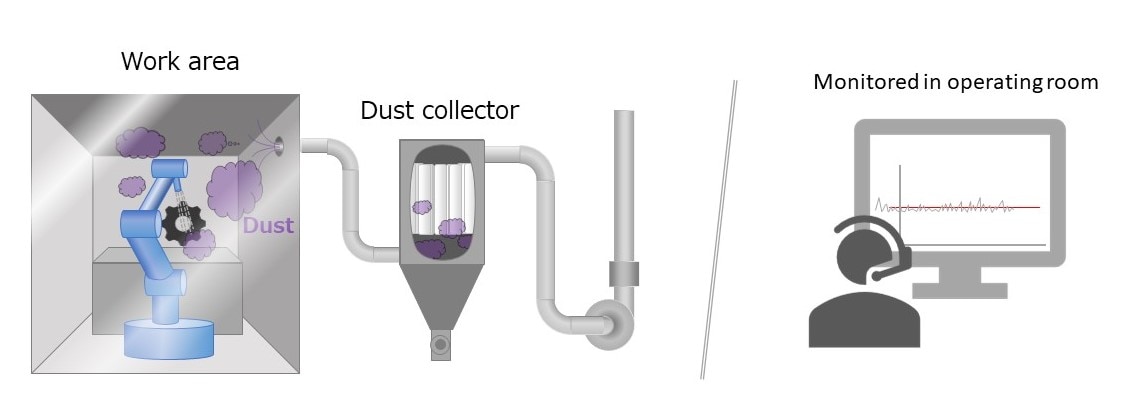

However, if the dust collector were to break down, the booth would be filled with magnesium powder, again posing the danger of a dust explosion.

To solve this problem, it was necessary to measure the dust concentration in the booth.

If the dust collector malfunctions,

there is a risk of dust explosion!

Air dust monitor solves the problem!

Air Dust Monitor is a dust indicator specialized for monitoring dust emissions from machinery and equipment operating indoors and outdoors at factories and construction sites.

It can be used to predict the beginning of dust leakage, prevent dust from being emitted indoors or outdoors, and confirm the effectiveness of dust collection measures.

Features of Air Dust Monitor

Portable

Compact design allows for a wide choice of installation locations.

Self-suction function

Built-in fan self-sufficiently draws air from installation site for measurement.

Equipped with

external output

terminal

Equipped with analog output and contact alarm according to dust concentration. It can be used for alarms and equipment control.

Air Dust Monitor

Air Dust Monitor is a dust indicator specialized for monitoring dust emissions from machinery and equipment operating indoors and outdoors at factories and construction sites.

It can be used to predict beginning of dust leakage, prevent dust emissions indoors and outdoors, and confirm the effectiveness of dust collection measures.

Three lineups are available for various situations.

Related articles

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.