Wiring cost is reduced to 1/2

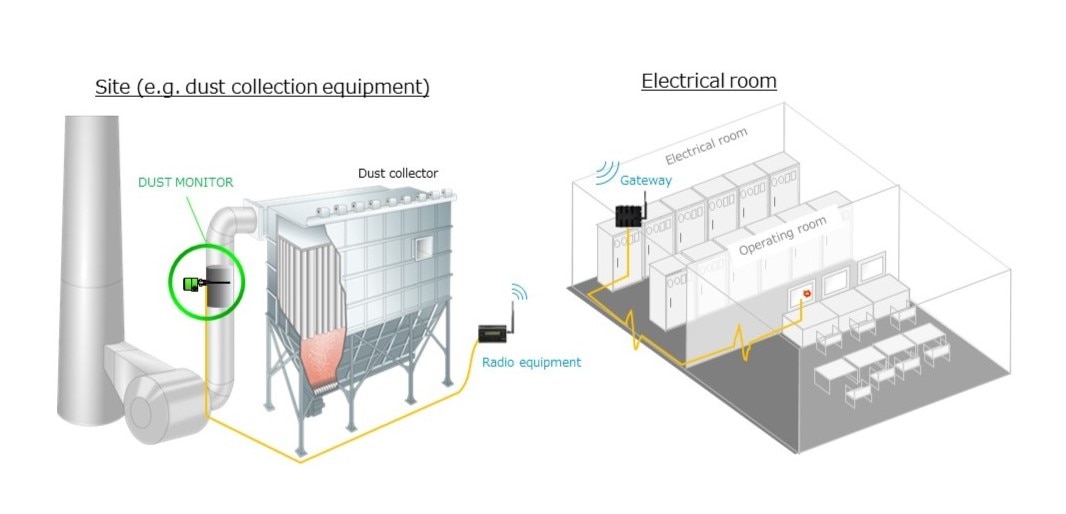

Various sensors and devices are used in factories to automate equipment and for safety measures. However, wiring work tends to cost more than sensors. In this issue, we will introduce an application for reducing wiring costs, using the installation of dust monitors as an example.

On-site Issues

Wiring burden is too large to install Dust monitor

Dust monitor + LoRa wireless solves the problem!

Effects of introduction

Wiring cost 1/2

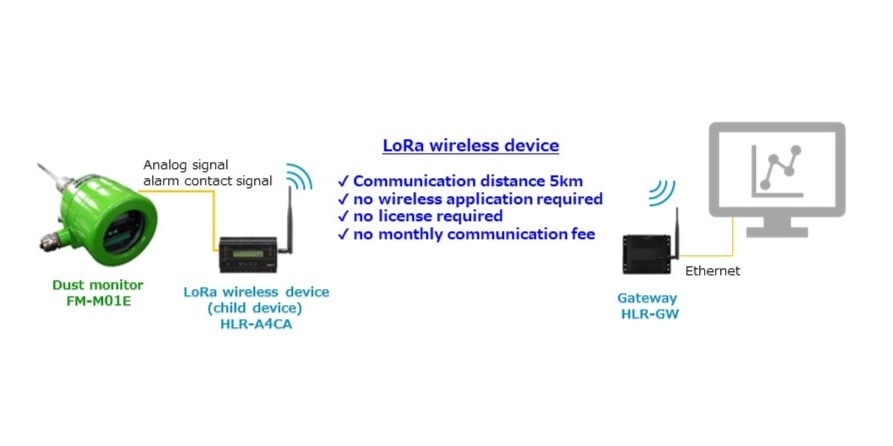

This is a comparison of wiring (wired) and LoRa wireless devices. "Wiring cost 1/2" is a comparison of wiring cost required when distance between Dust monitor installation location and monitoring room is 100m away, minus LoRa wireless cost. Therefore, the further away actual wiring distance is, the greater the effect.

- Not only dust monitors, but also various other sensors can be made wireless to reduce costs.

Dust Monitor

Dust Monitor is a dust indicator (dust concentration meter) specialized for monitoring dust emissions from dust collectors.

It detects the beginning of dust leakage, leading to not only predictive maintenance (predictive maintenance) but also labor and cost savings.

Related Articles

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

© Matsushima Measure Tech Co., Ltd.