Predicts leakage of valuable raw materials

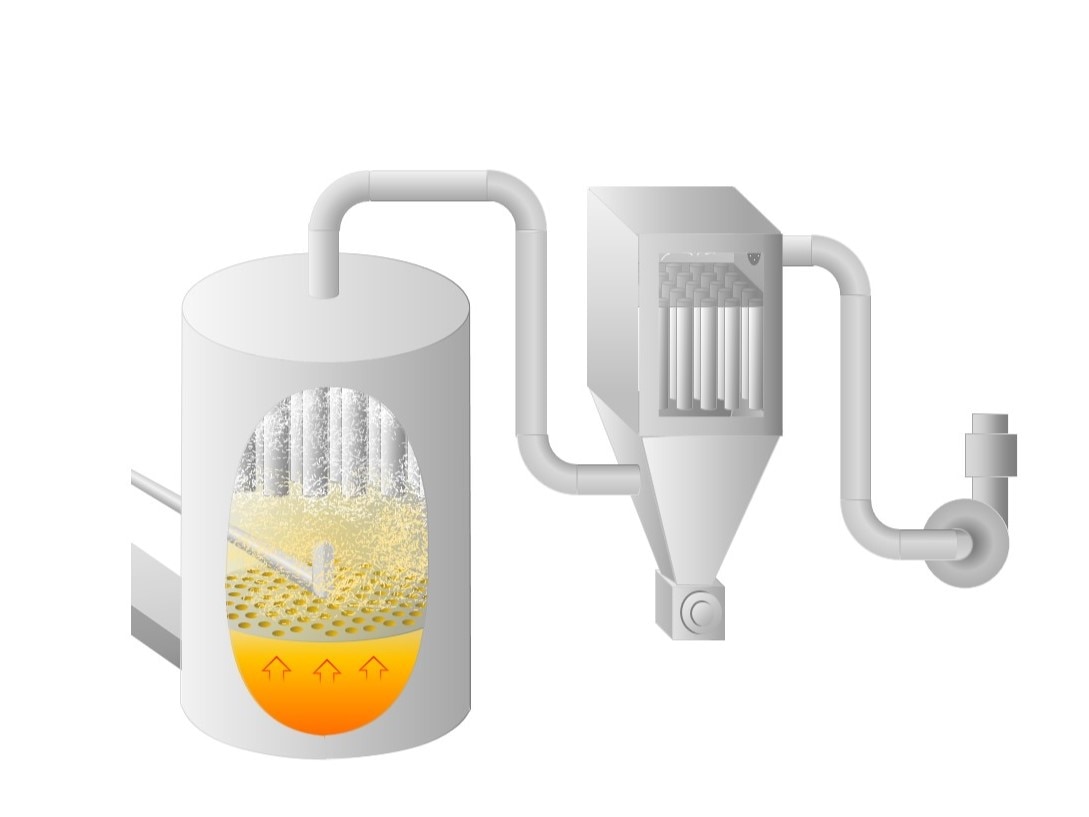

Fluidized bed granulation drying equipment is used to produce granular pharmaceuticals. Raw powder and binding liquid are blown into the equipment and dried with hot air to form granules, which are then collected using a dust collector or cyclone.

On-site issues

At a plant, granular products that should have been collected by a dust collector were occasionally leaking, and it was necessary to take measures to prevent leakage of valuable raw materials.

Sudden leakage from dust collector

is an issue

Dust Monitor is the

solution!

Notification of

Invisible leaks

This is where we propose our Dust Monitor.

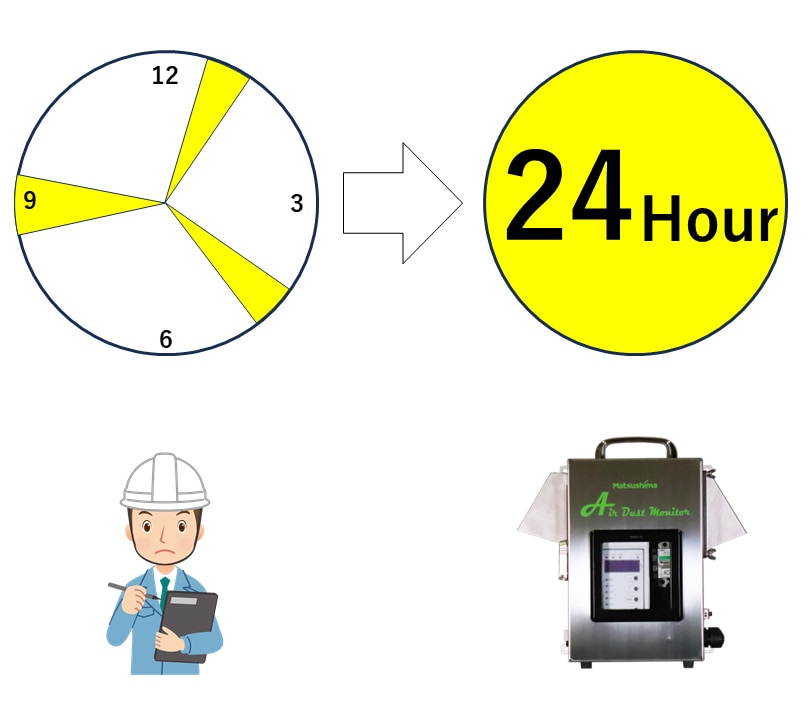

The Dust Monitor continuously monitors dust leaking from dust collectors with a high sensitivity of 0.1 mg/m3 for 24 hours a day.

Only three settings are required for adjustment: range, integration time, and alarm time. Compared to optical dust monitors, it can be installed and maintained at a lower cost in terms of both initial and running costs.

It is easy to maintain, too.

The Dust Monitor continuously monitors dust leaking from dust collectors with a high sensitivity of 0.1 mg/m3 for 24 hours a day.

Only three settings are required for adjustment: range, integration time, and alarm time. Compared to optical dust monitors, it can be installed and maintained at a lower cost in terms of both initial and running costs.

It is easy to maintain, too.

Continuous monitoring

to"visualize"

initial leakage from dust collector

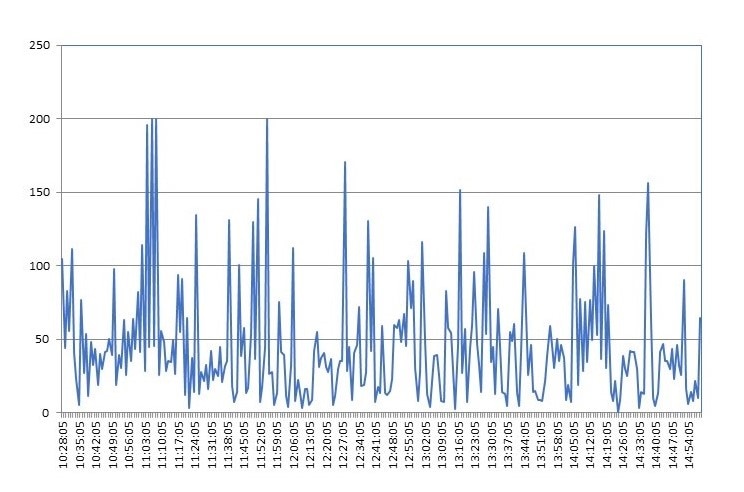

Continuous monitoring allows dust leakage due to initial deterioration or damage of filter to be recorded as a trend.

Effects after introduction

Reduction of

raw material losses

It can detect leaks from minute leakage stage, when filter begins to break, so valuable raw materials are not leaked.

Labor saving

Because it can be dealt with before damage is extensive, cleanup work and other cleanup efforts are reduced.

Reduction of

maintenance costs

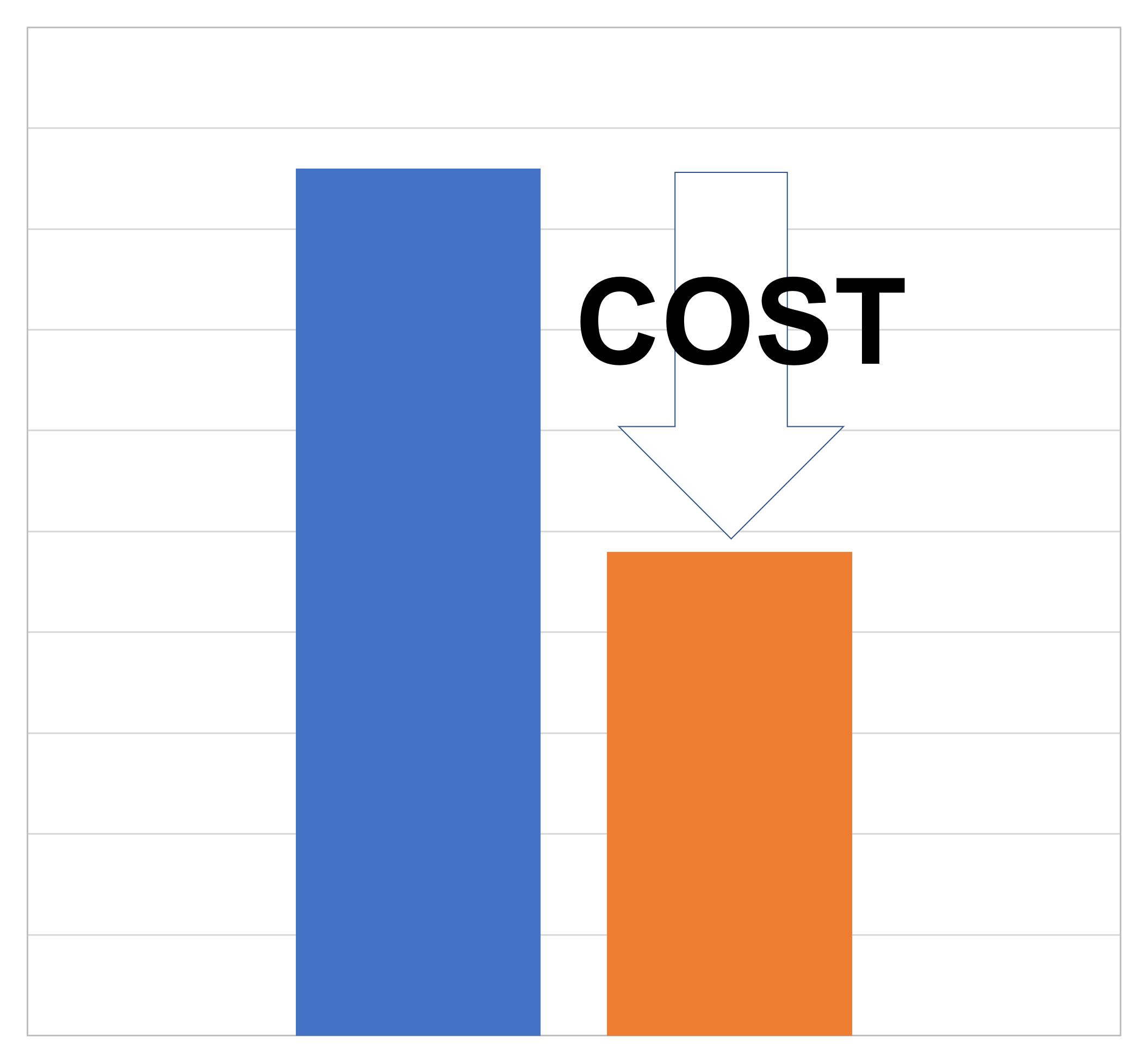

Filter can be used up to the end, eliminating need for periodic filter changes. This leads to cost savings.

Dust Monitor

Dust Monitor is a dust indicator (dust concentration meter) specialized for monitoring dust emissions from dust collectors.

It detects beginning of dust leakage, leading to not only predictive maintenance (predictive maintenance) but also labor and cost savings.

Related articles

Please feel free to ask us if you have any questions

or you want our support. ⇩⇩⇩

Please feel free to contact us if you have any inquiries.

Click here to download documents.

© Matsushima Measure Tech Co., Ltd.